Automated Fast-Flow Synthesis of Peptide-PNA Conjugates: A Transformative Platform for Accelerated Therapeutic Development

The therapeutic potential of peptide nucleic acids (PNAs) is often limited by challenging synthesis and poor cellular delivery.

Automated Fast-Flow Synthesis of Peptide-PNA Conjugates: A Transformative Platform for Accelerated Therapeutic Development

Abstract

The therapeutic potential of peptide nucleic acids (PNAs) is often limited by challenging synthesis and poor cellular delivery. This article explores the emergence of automated, high-temperature fast-flow synthesizers as a transformative solution, enabling the rapid and efficient production of peptide-PNA conjugates (PPNAs). We cover the foundational principles of PNA technology and its inherent challenges, detail the engineering and operation of automated flow platforms, provide strategies for optimizing synthesis and enhancing bioavailability, and validate the platform's utility through compelling biological applications in antivirals and antibacterials. This overview is tailored for researchers, scientists, and drug development professionals seeking to leverage this efficient technology for advanced antisense therapy development.

Peptide Nucleic Acids (PNAs): Unlocking Potential Through Synthesis and Delivery

This application note details the superior biophysical properties of Peptide Nucleic Acids (PNAs), focusing on their enhanced stability and binding affinity compared to natural nucleic acids. PNAs, with their unique N-(2-aminoethyl)glycine backbone, exhibit remarkable resistance to enzymatic degradation and form more stable duplexes with complementary DNA and RNA. Framed within research on automated synthesis platforms, this document provides validated protocols and quantitative data to support the integration of PNA conjugates into modern drug discovery pipelines, offering researchers a practical guide to leveraging these advanced biomolecules.

Peptide Nucleic Acids (PNAs) are synthetic nucleic acid analogs in which the native sugar-phosphodiester backbone is replaced by an uncharged, achiral backbone composed of repeating N-(2-aminoethyl)glycine units [1] [2]. This fundamental structural modification confers several superior properties over natural DNA and RNA. The neutral polyamide backbone eliminates electrostatic repulsion with complementary nucleic acid strands, leading to significantly higher binding affinity and sequence specificity [1]. Furthermore, the PNA backbone is resistant to degradation by both nucleases and proteases, granting it exceptional metabolic stability in biological environments, a critical advantage for therapeutic applications [1] [2].

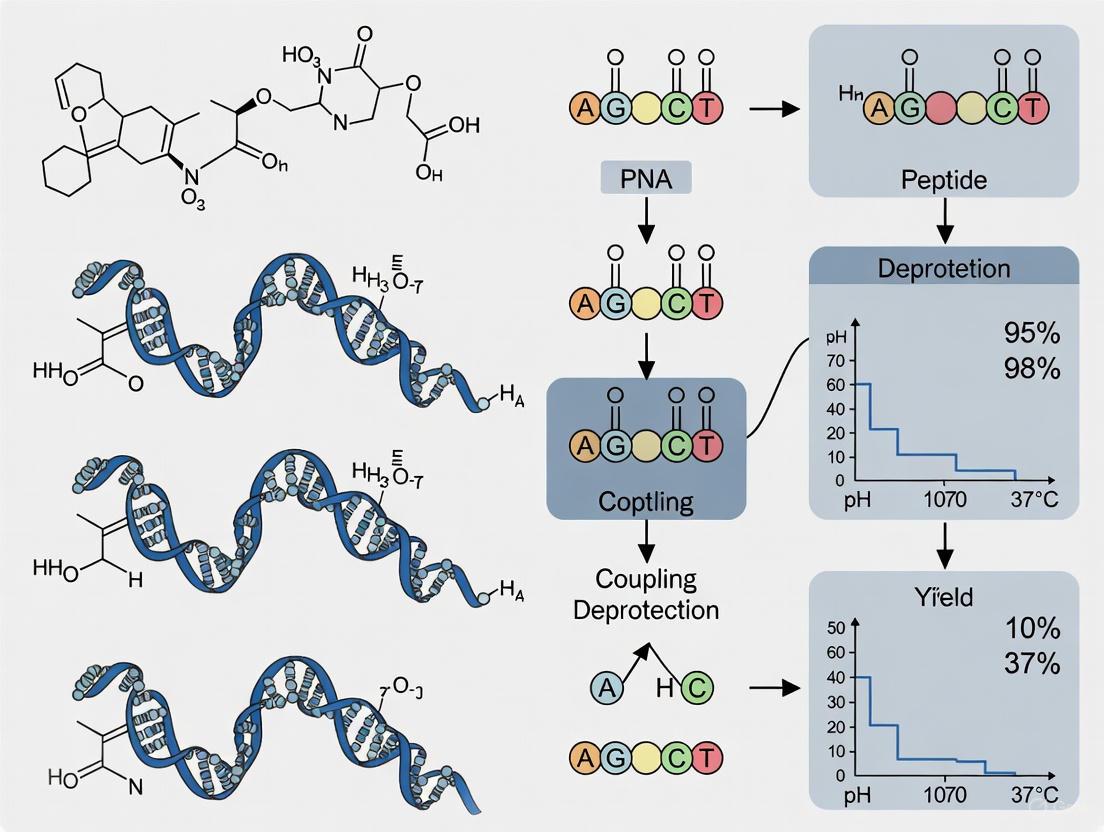

The following diagram illustrates the core structure and binding modes of PNA compared to DNA.

PNA's synthetic nature allows for extensive backbone and nucleobase modifications, enabling fine-tuning of properties like solubility, specificity, and cellular uptake [1] [3]. These characteristics make PNA a powerful tool in antisense therapy, molecular diagnostics, and biotechnology. The recent development of automated, high-throughput synthesis platforms for peptide-PNA conjugates (PPNAs) has further accelerated their application in drug discovery and nanotechnology, making robust protocols for their production and evaluation more essential than ever [4] [5].

Quantitative Analysis: PNA vs. Natural Nucleic Acids

The superior performance of PNA is quantitatively demonstrated through its enhanced thermal stability and binding properties. The data below compare PNA-DNA duplexes with natural nucleic acid duplexes.

Table 1: Comparative Thermal Stability of Nucleic Acid Duplexes (15-mer sequences)

| Duplex Type | Average Melting Temperature (Tm) | Effect of Single Mismatch (ΔTm) | Ionic Strength Dependence |

|---|---|---|---|

| PNA-DNA | ~70 °C [1] | ~ -15 °C [2] | Low [2] |

| DNA-DNA | ~55 °C [1] | ~ -11 °C [2] | High |

| PNA-RNA | Higher than DNA-RNA [5] | More destabilizing [2] | Low |

The elevated melting temperature of PNA-DNA duplexes, a direct result of the lack of inter-strand electrostatic repulsion, underscores PNA's higher binding affinity [1]. The greater destabilization caused by a single base mismatch highlights its exceptional sequence specificity, a crucial feature for diagnostic applications and therapeutic target engagement [2].

Recent advances in synthesis have enabled the production of complex PNA architectures with optimized properties. For instance, automated flow synthesis has been used to produce cyclic PNA and PPNA structures with 2- to 12-residue sequences achieving up to 95% crude purity, while also demonstrating remarkable nuclease resistance and permeability [4] [6].

Experimental Protocols

Protocol 1: Automated Fast-Flow Synthesis of PNA Conjugates

This protocol describes the automated synthesis of peptide-PNA conjugates (PPNAs) using a fast-flow instrument, reducing coupling times to seconds and improving crude purity [5].

- Objective: To synthesize PPNA conjugates in a single, fully automated run with high efficiency and purity.

- Principle: The method utilizes solid-phase synthesis with a flow-based instrument. High-temperature flow chemistry (70 °C) accelerates amide bond formation and reduces on-resin aggregation, enabling the synthesis of longer sequences without capping steps [5].

Materials & Reagents

- Resin: Rink Amide resin (0.5 mmol/g) [5].

- Monomers: Fmoc/Bhoc protected PNA monomers [5] [7].

- Activator: PyAOP ((7-Azabenzotriazol-1-yloxy)trispyrrolidinophosphonium hexafluorophosphate) [5].

- Base: DIEA (N,N-Diisopropylethylamine) [5].

- Solvent: Anhydrous DMF (Dimethylformamide) [5].

- Deprotection Reagent: 20% (v/v) Piperidine in DMF [5].

Procedure

- Reactor Setup: Load 15 mg of Rink Amide resin (0.5 mmol/g) into the reusable reactor body for a 7.5 μmol scale synthesis [5].

- Coupling Cycle:

- Deprotection: Piperidine solution flows through the reactor to remove the Fmoc protecting group. The temperature is maintained at approximately 40 °C for this step to minimize nucleobase adduct formation [5].

- Repetition: Steps 2 and 3 are repeated for each monomer addition. The entire synthesis cycle per residue is completed within 3 minutes [5].

- Cleavage & Purification: After sequence assembly, the crude PPNA is cleaved from the resin using a TFA-based cocktail, precipitated, and purified via reverse-phase HPLC [5] [3].

Protocol 2: Evaluating Cellular Delivery with CPP-PNA Complexes

This protocol outlines a method for forming non-covalent complexes between PNA and cell-penetrating peptides (CPPs) to evaluate and optimize cellular delivery in vitro [7].

- Objective: To establish and optimize non-covalent PNA-CPP complexes for efficient delivery of PNAs to the cell nucleus.

- Principle: Cationic CPPs form complexes with neutral PNA molecules through electrostatic and hydrophobic interactions, facilitating uptake across cell membranes. Incorporating a nuclear localization signal (NLS) further enhances nuclear delivery [7].

Materials & Reagents

- PNA: Synthesized PNA with a C-terminal NLS sequence (e.g., Pro-Lys-Lys-Lys-Arg-Lys-Val-amide) [7].

- CPPs: TP10, Tat, or TD2.2, each containing an NLS fragment [7].

- Cell Line: Adherent cell line relevant to the study (e.g., human ovarian epithelial cancer cell line SKOV3 [1]).

- Staining Solution: NHS-fluorescein for PNA labeling [7].

- Assay Kits: MTT cell viability assay kit.

Procedure

- Complex Formation:

- Prepare stock solutions of PNA and each CPP (TP10, Tat, TD2.2) in an appropriate buffer (e.g., water or PBS).

- Mix PNA and CPP at various molar ratios (e.g., 1:1 to 1:20) and incubate for 15-30 minutes at room temperature to allow complex formation [7].

- Cell Seeding and Treatment:

- Seed cells in a 24-well or 96-well plate and culture until they reach 60-80% confluency.

- Replace the medium with fresh medium containing the pre-formed PNA-CPP complexes. Include untreated cells as a control.

- Incubation and Analysis:

- Incubate cells for a predetermined period (e.g., 4-24 hours) at 37°C and 5% CO₂.

- Efficiency Analysis: For fluorescently labeled PNA, analyze cellular uptake using flow cytometry (e.g., FACS) and confocal microscopy [7] [3].

- Viability Assessment: Perform an MTT assay according to the manufacturer's instructions to assess potential cytotoxicity of the complexes [7].

- Optimization: Compare delivery efficiency of different CPPs and molar ratios to identify the optimal conditions, typically indicated by high fluorescence intensity (efficient delivery) and high cell viability.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents for PNA Synthesis and Application

| Reagent / Material | Function / Application | Examples & Notes |

|---|---|---|

| Fmoc/Bhoc PNA Monomers | Building blocks for solid-phase PNA synthesis. | Commercially available from suppliers like Panagene; Bhoc protects the nucleobase [7]. |

| Diaminonicotinic Acid (DAN) Linker | Enables on-resin head-to-tail cyclization for cyclic PNA/PPNA synthesis [4]. | Critical for constructing cyclic architectures with improved stability and permeability. |

| Cell-Penetrating Peptides (CPPs) | Enhance cellular uptake of PNA conjugates. | TP10, Tat, TD2.2; often include an NLS for nuclear delivery [7]. |

| PyAOP / HATU | Coupling agents for efficient amide bond formation during synthesis. | Used in automated flow and manual synthesis protocols [5] [3]. |

| Cyclopentane-Modified Monomers | Backbone modification to enhance brightness in FIT-PNA RNA sensors and improve binding [3]. | e.g., cpG; introduces conformational constraint. |

| Forced Intercalation (FIT) Probes | Surrogate bases (e.g., BisQ) used in FIT-PNA for fluorescent RNA detection [3]. | Fluorescence increases upon hybridization with complementary RNA target. |

| Acetyl-pepstatin | Acetyl-pepstatin, CAS:56093-98-2, MF:C31H57N5O9, MW:643.8 g/mol | Chemical Reagent |

| Decanoyl-RVKR-CMK | Decanoyl-RVKR-CMK, MF:C34H66ClN11O5, MW:744.4 g/mol | Chemical Reagent |

Application Workflow: From Design to Functional Analysis

The following diagram summarizes the integrated workflow for developing and evaluating a functional PNA-based molecule, from design through synthesis to activity validation.

This end-to-end workflow, powered by automated synthesis, enables the rapid generation and testing of PNA constructs, significantly accelerating the development cycle for research and therapeutic applications [4] [5].

Peptide Nucleic Acids (PNAs) are synthetic oligonucleotide mimics where the sugar-phosphate backbone is replaced by an uncharged N-(2-aminoethyl)glycine backbone [8] [1]. This structure confers superior binding affinity and specificity for complementary DNA and RNA, along with high metabolic stability against nucleases and proteases [8] [9]. Despite these advantages, the translation of PNA technology into clinical and widespread practical use has been hampered by three persistent challenges: inherently poor aqueous solubility, limited cellular permeability, and difficulties in synthesizing certain sequences [8] [9] [10]. This application note details these hurdles and frames them within the context of modern solutions, particularly automated synthesis platforms for peptide-PNA conjugates (PPNAs), which are pivotal for advancing PNA-based research and drug development.

The Solubility Challenge

The neutral and relatively hydrophobic nature of the PNA backbone significantly limits its solubility in aqueous solutions, a problem exacerbated for purine-rich sequences, particularly those with consecutive guanines (G) [8] [11]. This can lead to molecular aggregation and handling issues during synthesis and application [10] [12].

Strategies for Solubility Enhancement

- Terminal Modifications: Incorporating a lysine residue at the C-terminus (or both termini) introduces a positive charge, improving water solubility without significantly affecting hybridization properties [8] [12].

- Chemical Linkers: Incorporating hydrophilic spacers, such as the AEEA linker (2-(2-aminoethoxy)ethoxy acetic acid), between the PNA sequence and any conjugated moiety (e.g., a peptide or label) can dramatically improve solubility [11] [12].

- Backbone Engineering: Incorporating cationic groups into the PNA backbone itself, or using γ-substituted chiral PNA monomers, can minimize self-aggregation and enhance water solubility [1] [10].

Table 1: Strategies to Overcome PNA Solubility and Permeability Challenges

| Challenge | Specific Issue | Proposed Solution | Mechanism of Action | Key Benefit(s) |

|---|---|---|---|---|

| Poor Solubility | General hydrophobic aggregation | C-terminal Lysine | Introduces a positive charge | Electrostatic stabilization in aqueous buffer [8] [12] |

| Purine-rich sequence aggregation | Incorporation of AEEA Spacers | Increases hydrophilicity and steric separation | Reduces intermolecular stacking and aggregation [11] [12] | |

| Folding & compact structures | γ-PNA Backbone Modification | Imparts conformational control and introduces chirality | Minimizes self-aggregation; enhances binding affinity and specificity [1] [10] | |

| Cellular Permeability | Poor membrane penetration | Conjugation to Cell-Penetrating Peptides (CPPs) | Utilizes energy-dependent/independent translocation mechanisms | Actively facilitates cellular uptake across lipid bilayers [9] [5] |

| Negatively charged targets | Use of Cationic CPPs (e.g., (KFF)3K) | Promotes electrostatic interaction with anionic cell surfaces | Enhances initial adhesion and concentration at membrane interface [9] | |

| Endosomal entrapment | Exploration of novel cyclic PPNAs | Alters internalization mechanism and intracellular trafficking | Potential for improved endosomal escape and bioavailability [4] |

The Cellular Permeability Hurdle

A major bottleneck for in vivo PNA applications is poor cellular uptake. Unmodified PNAs are not efficiently internalized by eukaryotic cells and are rapidly cleared from the body, primarily through renal excretion, with a half-life as short as 17 minutes in rats [8] [9].

Conjugation as the Primary Strategy

The most prevalent and successful strategy to overcome the delivery barrier is the covalent conjugation of PNA to carrier molecules, with Cell-Penetrating Peptides (CPPs) being the most prominent [9] [5]. CPPs are short, often cationic, peptides that facilitate transport across cellular membranes.

Table 2: Efficacy of CPP-PNA Conjugates in Antimicrobial Applications

| CPP-PNA Conjugate | PNA Target Gene | Target Organism | Minimal Inhibitory Concentration (MIC) | Reference |

|---|---|---|---|---|

| (KFF)3K-PNA | acpP |

E. coli K-12 | 0.5 - 1 µM | [9] |

| (KFF)3K-PNA | acpP |

E. coli MDR | 25 µM | [9] |

| (KFF)3K-PNA | acpP |

K. pneumoniae ATCC 13883 | 2 µM | [9] |

| (KFF)3K-PNA | rpoA |

L. monocytogenes clinical isolates | 2 - 32 µM | [9] |

| (KFF)3K-PNA | gyrA |

S. pyogenes M49 | 10 µM | [9] |

Troubles in PNA Synthesis

PNA oligomers are synthesized using Solid-Phase Peptide Synthesis (SPPS) methodologies [10]. However, the process is often more challenging than conventional peptide synthesis due to the poor solubility of monomers, and the tendency for the growing PNA chain to form intra- and inter-chain aggregates on the resin, leading to inefficient coupling and low yields of full-length product [10] [11]. These issues are particularly pronounced for longer sequences (>15-mers) and purine-rich sequences [5] [12].

Automated High-Temperature Flow Synthesis: A Modern Solution

Recent advances in automated flow synthesis present a robust solution to these synthetic challenges [4] [5]. This technology platform offers several critical advantages over traditional batch synthesis methods:

- Dramatically Reduced Coupling Times: Each amide bond formation is completed in approximately 10 seconds [5].

- High-Temperature Operation: Synthesis is performed at elevated temperatures (e.g., 70°C), which reduces on-resin aggregation and side reactions, improving crude purity [5].

- Single-Shot Conjugation: The high coupling efficiency enables the direct, fully automated synthesis of long PNA sequences conjugated to peptides (PPNAs) in a single, uninterrupted run [4] [5].

- Rapid Production: This platform can synthesize a library of PPNAs in a single day, significantly accelerating structure-activity relationship studies [5].

Integrated Experimental Protocols

Protocol: Automated Flow Synthesis of PPNA Conjugates

This protocol is adapted from the automated high-purity fast-flow synthesis method for cyclic peptide-PNA conjugates [4] and the synthesis of anti-SARS-CoV-2 PPNAs [5].

Resin Preparation

- Solid Support: Use a Rink Amide Am resin (e.g., XAL-PEG-PS or PAL-PEG-PS) with a loading capacity of ~0.5 mmol/g.

- Reactor Loading: Load 15 mg of resin into a dedicated flow reactor designed for a 7.5 μmol scale synthesis.

Synthesis Cycle Programming The automated flow synthesizer should be programmed to execute the following cycle for each monomer addition, with a total cycle time of approximately 3 minutes:

- Deprotection: Pump 20% (v/v) piperidine in DMF through the reactor at a flow rate of 2.5 mL/min for 1 minute, maintaining the reactor temperature at 40°C.

- Washing: Flush the reactor with dry DMF or NMP.

- Coupling:

- Activation: Merge separate streams of 0.2 M PNA monomer in NMP, 0.2 M activator (e.g., HATU or PyAOP) in DMF, and 0.6 M base (e.g., DIEA) in DMF.

- The merged mixture passes through a heating loop at 70°C to form the activated ester.

- Reaction: The activated ester solution flows through the resin-packed reactor, maintained at 70°C, for 10 seconds to complete the coupling.

- Washing: Flush the reactor with solvent to remove excess reagents. Note: The high efficiency of this process typically eliminates the need for a capping step [5].

Final Cleavage and Deprotection

- Cleave the crude PPNA from the resin and remove permanent protecting groups (e.g., Bhoc on nucleobases) by treating with a cocktail of TFA:m-cresol (95:5) for 5-90 minutes (time depends on the resin linker).

- Precipitate the product in cold diethyl ether.

- Purify the PPNA by reverse-phase HPLC (C18 column, 0.1% TFA in water/acetonitrile gradient) and characterize by LC-MS.

Protocol: Evaluating Cellular Permeability and Efficacy

Parallel Artificial Membrane Permeability Assay (PAMPA)

- Purpose: A high-throughput method to screen the passive permeability of synthesized PNA/PPNA libraries [4].

- Procedure:

- Dilute test compounds in a pH 7.4 buffer.

- Add the donor solution to the membrane filter, which is coated with a phospholipid mixture mimicking the cell membrane.

- Place the donor plate over an acceptor plate containing blank buffer.

- Incubate the assembly for several hours.

- Analyze the concentration of compound in the acceptor well using UV spectroscopy or HPLC to calculate the apparent permeability (Papp).

Cell-Based Splice-Correction Assay

- Purpose: To functionally validate the intracellular activity and delivery efficiency of antisense PPNAs [5].

- Procedure (e.g., using an Enhanced Green Fluorescence Protein (EGFP) reporter system):

- Transfert cells (e.g., HeLa) with a reporter gene (e.g., β-thalassemia IVS2-654 mutant) harboring a mutated intron that causes incorrect splicing and loss of EGFP fluorescence.

- Treat the cells with the test PPNA, which is designed to bind the mutant splice site and restore correct splicing.

- Include controls: untreated cells and transfected PNA (without CPP) complexed with a standard transfection reagent.

- After 24-48 hours, measure the fluorescence intensity. A successful, cell-permeant PPNA will produce a dose-dependent increase in EGFP fluorescence, indicating successful internalization, correct target engagement, and functional splice correction.

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for PNA Synthesis and Conjugation

| Item | Function in Research | Specific Example / Note |

|---|---|---|

| Fmoc/Bhoc PNA Monomers | Building blocks for solid-phase synthesis using Fmoc chemistry. Most common and compatible with DNA/peptide synthesizers [11] [12]. | A, C, G, T monomers (e.g., LK5001-LK5004). |

| AEEA Spacer (LK5005) | Hydrophilic linker to improve solubility and conjugation efficiency between PNA and peptides/labels [11] [12]. | Essential for N-terminal labelling. |

| Cell-Penetrating Peptides | Carrier molecules covalently conjugated to PNA to enable cellular uptake. | (KFF)3K; various cationic and amphipathic peptides [9] [5]. |

| Activators / Coupling Reagents | To activate the PNA monomer's carboxylic acid for amide bond formation with the growing chain. | HATU, PyAOP, PyBOP [5] [12]. |

| Orthogonally Protected Lysine | Allows for site-specific attachment of multiple labels or functional groups via its side chain. | Fmoc-Lys(Dde)-OH or Fmoc-Lys(Mtt)-OH for selective deprotection [11]. |

| Rink Amide Resin (PAL/XAL) | Solid support that yields a C-terminal carboxamide upon cleavage. Low loading (<0.2 mmol/g) is recommended to avoid aggregation [12]. | XAL-PEG-PS enables faster cleavage (~5 min) [12]. |

| Cleavage Cocktail | To simultaneously cleave the PNA from the resin and remove permanent base protections (Bhoc). | TFA with scavengers (e.g., 5% m-cresol) [12]. |

| Izumenolide | Izumenolide, MF:C40H74O14S3, MW:875.2 g/mol | Chemical Reagent |

| Griselimycin | Griselimycin, MF:C57H96N10O12, MW:1113.4 g/mol | Chemical Reagent |

Strategic Workflow and Visualization

The following diagram illustrates the integrated strategic workflow for overcoming the key hurdles in PNA therapeutic development, from design and synthesis to functional validation.

Diagram 1: Integrated strategy for PNA development

The synthesis of these complex molecules on an automated platform can be visualized as a highly efficient, sequential process, as shown in the workflow below.

Diagram 2: Automated flow synthesis workflow

The hurdles of solubility, permeability, and synthesis are significant but surmountable. Strategic molecular design, conjugation to carrier peptides, and leveraging cutting-edge automated synthesis platforms provide a cohesive and powerful strategy to overcome these challenges. The protocols and data summarized herein provide a roadmap for researchers to efficiently produce and test functional PNA conjugates, thereby accelerating the development of PNA-based therapeutics and diagnostics.

The efficacy of many modern therapeutic and diagnostic agents is fundamentally constrained by the impermeable nature of the cellular membrane. This barrier poses a significant challenge for the intracellular delivery of macromolecular cargoes such as peptides, proteins, and nucleic acids. Cell-penetrating peptides (CPPs) have emerged as a powerful solution to this delivery imperative. These short peptides (typically fewer than 30 amino acids) facilitate the cellular uptake of diverse cargoes, ranging from small chemical compounds to large fragments of DNA, through covalent linkage or non-covalent interactions [13] [14]. Their ability to operate in a often receptor- and energy-independent manner makes them exceptionally versatile tools [14]. The integration of CPP functionality into therapeutic and diagnostic agents is particularly relevant within the context of automated platforms for peptide-PNA (Peptide Nucleic Acid) conjugate synthesis. This document outlines the core principles of CPPs, provides detailed protocols for their application, and explores their use in advanced, automated research workflows.

CPP Fundamentals and Classification

Cell-penetrating peptides are categorized based on their physical and chemical properties, which directly influence their interaction with biological membranes and their mechanism of internalization. The table below summarizes the primary classes of CPPs.

Table 1: Classification of Cell-Penetrating Peptides

| Class | Key Characteristics | Example Sequences | Origin/Type |

|---|---|---|---|

| Cationic | Rich in positively charged amino acids (e.g., Arg, Lys); strong affinity for negatively charged membrane components [13] [15]. | TAT (GRKKRRQRRRPPQ) [15], Polyarginine (Rn) [15], Penetratin (RQIKIWFQNRRMKWKK) [15] | HIV-1 TAT protein [13], Synthetic [15], Antennapedia protein [15] |

| Amphipathic | Contain alternating polar/charged and non-polar/hydrophobic residues; can form secondary structures [13] [15]. | MAP (KLALKLALKALKAALKLA) [15], Transportan (GWTLNSAGYLLGKINLKALAALAKKIL) [15], CADY (GLWRALWRLLRSLWRLLWRA) [13] | Model Amphipathic Peptide [15], Chimeric (Galanin–Mastoparan) [15], ppTG11 derivative [13] |

| Hydrophobic | Contain only apolar residues or crucial hydrophobic groups; low net charge [13]. | Information not specific in results | Synthetic/Natural [13] |

The cellular uptake of CPPs occurs through multiple, often concurrent, pathways. The precise mechanism can depend on factors such as the peptide's sequence, the type of cargo, and the target cell [13] [16]. The main mechanisms are categorized into two broad groups: endocytosis-mediated entry and direct penetration [16].

Application Note: CPPs for Nucleic Acid Delivery

Nucleic acid-based therapeutics, including siRNA, antisense oligonucleotides, and plasmid DNA, represent a promising frontier for treating genetic disorders, cancer, and viral infections. However, their high molecular weight and negative charge impede efficient cellular uptake [13]. CPPs overcome this barrier, facilitating the intracellular delivery of these macromolecules.

Key Considerations for CPP-Nucleic Acid Formulations

The formation of CPP-nucleic acid complexes can be achieved through two primary strategies:

- Covalent Conjugation: The cargo is linked to the CPP via stable (e.g., amide, thiazolidine) or cleavable (e.g., disulfide) bonds. While disulfide linkages are common due to their susceptibility to cleavage in the reductive intracellular environment, a concern is that the covalent bond may alter the biological activity of the nucleic acid [13].

- Non-Covalent Complexation: This strategy uses electrostatic and hydrophobic interactions to form nanoparticles. Short amphipathic CPPs like MPG and Pep-1 are effective carriers for this purpose. A significant advantage is that cargoes can be delivered efficiently while maintaining full biological activity, and this method avoids the need for chemical modification of the cargo [13].

For siRNA delivery, non-covalent strategies have demonstrated a more significant biological response. For instance, MPG/siRNA complexes form stable nanoparticles that protect the siRNA, show a low degradation rate, and can be easily functionalized for specific targeting. This system has been successfully used both in cultured cells and in vivo in mouse blastocytes for robust gene regulation [13].

Table 2: CPP Applications in Nucleic Acid Delivery

| Cargo Type | CPP/Delivery System | Conjugation Method | Key Application & Outcome |

|---|---|---|---|

| siRNA | Transportan, Penetratin | Covalent (disulfide linkage) | Delivery of siRNA targeting luciferase or eGFP reporters [13]. |

| siRNA | MPG | Non-covalent complexation | Efficient gene silencing in vitro and in vivo; high stability and low degradation rate [13]. |

| siRNA | CADY | Non-covalent complexation | Secondary amphipathic peptide based on tryptophan and arginine; effective siRNA delivery [13]. |

| Plasmid DNA, Oligonucleotides | S413-PV | Not specified | Exploration for intracellular delivery of nucleic acids in a therapeutic context [16]. |

Experimental Protocols

Protocol 1: Automated Solid-Phase Synthesis of a Cationic CPP (e.g., TAT)

This protocol is adapted for an automated programmable platform like the SPPS Chemputer, which uses the Chemical Description Language (χDL) to digitize and execute synthetic procedures [17].

1. Resin Swelling

- Material: Appropriate solid support (e.g., PAL-PEG-PS or XAL-PEG-PS resin, load <0.2 mmol/g).

- Procedure: In the SPPS reactor, swell the resin in a suitable solvent (e.g., DMF) for 30-60 minutes under gentle nitrogen bubbling [17] [12].

2. Peptide Chain Assembly (Repeat for each amino acid)

- Fmoc Deprotection: Treat the resin with 20% piperidine in DMF (e.g., 2 x 9 mL, 15 min total). This can be monitored in real-time via UV monitoring to verify completion [17] [18] [19].

- Washing: Wash the resin multiple times with DMF.

- Amino Acid Coupling:

- Activation: Pre-activate the Fmoc-protected amino acid (0.5 M in DMF) with HATU (0.45 M in DMF) and DIPEA for a set time (e.g., 2.5 min).

- Coupling: Transfer the activated amino acid to the SPPS reactor and couple for a defined period (e.g., 1 x 30 min). Induction heating can be applied to accelerate coupling and improve crude purity [17] [18].

- Washing: Wash the resin with DMF to remove excess reagents.

3. Cleavage and Side Chain Deprotection

- Cleavage Cocktail: Transfer the peptide-bound resin to the precipitating unit. Add a cleavage cocktail such as TFA/Water/TIPS (90:5:5, v/v/v) and mix with low-pressure nitrogen flow for 2 hours [17].

- Alternative for PNA: For PNA conjugates, use TFA containing 5% m-cresol as a scavenger. Cleavage time is dependent on the support (90 min for PAL-PEG-PS, 5 min for XAL handle) [12].

4. Precipitation and Isolation

- Precipitation: In the precipitating unit, add the TFA/peptide mixture to pre-chilled diethyl ether (-20°C) and mix via nitrogen bubbling for 30 min.

- Washing: Filter the precipitate and wash several times with cold diethyl ether.

- Drying: Dry the peptide precipitate under vacuum, then dissolve in MeCN/Hâ‚‚O (1:1, v/v) for analysis [17].

Protocol 2: Forming Non-Covalent CPP-siRNA Complexes for Delivery

This protocol describes the formation of nanocomplexes using amphipathic CPPs like MPG or CADY for siRNA delivery [13].

1. Preparation of Solutions

- CPP Stock: Dissolve the CPP (e.g., CADY) in nuclease-free water or an appropriate buffer at a stock concentration of 100 µM.

- siRNA Stock: Dilute the siRNA to a stock concentration of 20 µM in nuclease-free water.

2. Complex Formation

- Mixing: In a microcentrifuge tube, rapidly mix the CPP and siRNA solutions at a predetermined molar ratio (e.g., 10:1 to 40:1 CPP:siRNA). The optimal ratio should be determined empirically for each CPP-siRNA pair.

- Incubation: Incubate the mixture for 15-30 minutes at 37°C to allow for stable nanoparticle formation.

3. Cellular Assay

- Cell Seeding: Seed cells in a 24-well plate to reach 50-70% confluency at the time of transfection.

- Transfection: Replace the growth medium with fresh medium. Add the CPP-siRNA complexes directly to the cells.

- Incubation: Incubate the cells for 1-4 hours at 37°C, then replace the transfection medium with fresh growth medium.

- Analysis: Assess gene silencing efficiency (e.g., via qRT-PCR or Western Blot) 48-72 hours post-transfection.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for CPP and Peptide-PNA Conjugate Research

| Item | Function/Description | Example/Note |

|---|---|---|

| Fmoc-PNA Monomers | Building blocks for automated PNA synthesis on DNA/peptide synthesizers [12]. | Supplied as 0.2M solutions in N-methylpyrrolidone (NMP); may require gentle heating to dissolve [12]. |

| Solid Support (Resin) | A universal support for Fmoc-based synthesis, producing a C-terminal amide [12]. | PAL-PEG-PS or XAL-PEG-PS (low load, <0.2 mmol/g) to avoid aggregation [12]. |

| Coupling Reagents | Activates the carboxylic acid of the monomer for coupling to the growing chain. | HATU or PyBOP, used with a base mixture of DIPEA and lutidine [17] [12]. |

| Cleavage Cocktail | Cleaves the peptide from the resin and removes acid-labile protecting groups. | TFA-based cocktails with scavengers (e.g., TIPS, water, m-cresol, phenol) [17] [12]. |

| Spacer Monomers (e.g., AEEA) | Improves solubility and provides a flexible spacer for labeling [12]. | Incorporation of two or more spacers between the PNA oligomer and a label (e.g., fluorescein, biotin) is recommended [12]. |

| Amphipathic CPPs (MPG, CADY) | For non-covalent delivery of cargoes like siRNA and proteins [13]. | Forms stable, non-covalent complexes that maintain full biological activity of the cargo [13]. |

| AD-8007 | AD-8007, MF:C22H26N2O, MW:334.5 g/mol | Chemical Reagent |

| SPL-IN-1 | SPL-IN-1, MF:C31H42N2O6S2, MW:602.8 g/mol | Chemical Reagent |

Workflow Integration: CPP-PNA Conjugates on an Automated Platform

The synthesis of peptide-PNA conjugates, which combine the gene-targeting ability of PNA with the delivery capability of CPPs, is a prime application for automated synthesizers. These platforms can integrate SPPS with valuable transformations like native chemical ligation (NCL) into a single, uninterrupted protocol [17]. The software's capability to flexibly control reagent movement allows for the automation of novel chemistry, including the synthesis of peptide-nucleic acids [18].

Cell-penetrating peptides are indispensable tools for overcoming the critical barrier of cellular membrane permeability. Their ability to ferry diverse cargoes into cells, combined with advanced automated synthesis platforms, unlocks new possibilities for research and drug development. The protocols and workflows outlined here provide a foundation for the reliable production and application of CPPs and CPP-PNA conjugates, facilitating the advancement of intracellular therapeutics and diagnostics.

Peptide Nucleic Acids (PNAs) represent a powerful class of synthetic oligonucleotide analogs with exceptional binding affinity and specificity toward complementary DNA and RNA sequences [9]. Their unique N-(2-aminoethyl)glycine backbone replaces the sugar-phosphodiester moiety of natural nucleic acids, conferring superior chemical, thermal, and enzymatic stability [5]. These properties make PNAs particularly valuable for antisense therapeutic development, molecular diagnostics, and biomedical research [9]. However, the transition of PNA-based technologies from research tools to clinical applications has been hampered by significant synthetic challenges inherent to manual and standard batch methods. These limitations constitute a critical bottleneck in PNA research and development, particularly for complex constructs like peptide-PNA conjugates (PPNAs) that require enhanced cellular delivery [5] [9].

The fundamental obstacle in PNA synthesis stems from the inherent properties of the PNA backbone itself. Unlike traditional peptides or oligonucleotides, PNA oligomers exhibit poor solubility and a strong tendency for aggregation, especially for purine-rich sequences [11]. This aggregation problem is exacerbated in standard batch synthesis protocols, where on-resin aggregation leads to decreased coupling efficiency and increased formation of deletion sequences and side products [5]. Additionally, longer PNA sequences (>15-mers) that are often necessary for optimal target affinity and specificity present particular challenges for conventional methods [5]. This application note examines these limitations through quantitative data and presents automated flow synthesis as a transformative solution.

Quantitative Analysis of Synthesis Limitations

Table 1: Comparative Performance of PNA Synthesis Methods

| Synthesis Parameter | Manual Batch Synthesis | Standard Automated Batch | Automated Fast-Flow |

|---|---|---|---|

| Coupling Time per Amide Bond | ~4 hours (for a 4-mer) [5] | 10 minutes (at 45°C) [5] | 10 seconds [5] |

| Crude Purity (4-mer Example) | 57% [5] | Not specified | 70% [5] |

| Typical Maximum Length | <15 monomers [5] [11] | <15 monomers [5] [11] | >15 monomers reliably [5] |

| Key Side Products | ~15% isomers, ~4% deletions, ~2% nucleobase adducts [5] | Higher deletion rates and nucleobase adducts at elevated temperatures [5] | Significantly reduced side products with optimized protocols [5] |

| Compatibility with Conjugate Synthesis | Requires multi-step, off-line conjugation strategies [20] | Limited by on-resin aggregation during extended sequences [5] | Single-shot synthesis of PNA-peptide conjugates [5] |

Table 2: Common Side Reactions in Standard Fmoc-Based PNA Synthesis

| Side Reaction | Cause | Impact on Product Quality | Common Mitigation Strategies |

|---|---|---|---|

| Base-Catalyzed Rearrangement | Extended exposure to piperidine during Fmoc deprotection [11] | ~0.3-0.4% contamination with 2-minute deprotection [11] | Minimize deprotection time; use microwave assistance [11] |

| Aspartimide Formation | Base-mediated side reaction during deprotection [5] | Sequence deletion and isomerization [5] | Addition of formic acid to deprotection solutions [5] |

| Nucleobase Adducts | Particularly problematic during high-temperature synthesis [5] | 7% observed in non-optimized flow synthesis [5] | Optimized deprotection temperature (~40°C) and base [5] |

| On-Resin Aggregation | Inter-chain hydrogen bonding of the PNA backbone [5] | Reduced coupling efficiency, increased deletion sequences [5] | Capping and double-couplings (often insufficient) [5] |

Experimental Protocols for Method Comparison

Protocol A: Manual Solid-Phase PNA Synthesis (Fmoc/Bhoc Chemistry)

This protocol outlines the traditional manual synthesis of a PNA oligomer, highlighting the time-intensive and laborious steps that contribute to the synthesis bottleneck.

- Resin Preparation: Use 100 mg of Rink Amide resin (loading capacity ~0.18 mmol/g). Pre-swell the resin in DMF or NMP for 30 minutes [5] [11].

- Deprotection Cycle: Treat the resin with 20% piperidine in DMF or NMP (2 x 5-10 minutes) to remove the Fmoc protecting group. Monitor deprotection by in-line UV-vis if available [5] [11].

- Coupling Cycle:

- Reagent Preparation: Dissolve 6 equivalents of Fmoc-PNA monomer in NMP. In a separate vessel, prepare a solution of 5.8 equivalents PyAOP activator and 6 equivalents each of DIEA and 2,5-lutidine in NMP [5].

- Reaction: Mix the activated monomer solution with the resin and agitate for 30-60 minutes to complete the coupling reaction [11].

- Capping: Introduce a capping solution (typically acetic anhydride) to block any unreacted chain ends to prevent deletion sequences [5] [11].

- Repetition: Repeat the deprotection and coupling cycles for each monomer in the sequence.

- Cleavage and Global Deprotection: Treat the resin with a cleavage cocktail containing 20% m-cresol in TFA for 2-4 hours to simultaneously cleave the product from the resin and remove Bhoc protecting groups from nucleobases [11].

- Precipitation and Purification: Precipitate the crude PNA in cold diethyl ether, isolate by centrifugation, and purify by reverse-phase HPLC (C18 column) using a water/acetonitrile gradient with 0.1% TFA [11].

Protocol B: Automated Fast-Flow Synthesis of a Peptide-PNA Conjugate

This protocol describes the automated, continuous-flow method that dramatically accelerates the synthesis of PNA and its conjugates.

- Instrument Setup: Utilize a fully automated flow synthesizer (e.g., iChemAFS) equipped with a central control computer, solution storage system, HPLC pumps, multiposition valves, heated reaction zones, and an in-line UV-vis detector [5] [4].

- Reactor Preparation: Pack a reusable reactor with 15 mg of 0.5 mmol/g Rink Amide resin (7.5 μmol scale) [5].

- Automated Synthesis Cycle (3 minutes per monomer):

- Activation and Coupling: Three HPLC pumps simultaneously draw PNA monomer (10 equiv), activator (PyAOP, 9.6 equiv), and base (DIEA, 30 equiv) from storage. The solutions are merged at a valve and passed through a 70°C heating loop to form the activated ester, which then flows through the 70°C resin-packed reactor. Amide bond formation is completed within 10 seconds at a flow rate of 2.5 mL/min [5].

- Deprotection: A piperidine solution is pumped through a room-temperature loop and mixed with the 70°C reactor, creating an optimal ~40°C environment for efficient Fmoc removal while minimizing nucleobase adducts [5].

- Monitoring: The in-line UV-vis detector monitors the Fmoc-piperidine adduct in the spent reagent stream to provide real-time feedback on deprotection efficiency [5].

- Direct Peptide Conjugation: Following PNA chain assembly, switch the reagent reservoirs to Fmoc-amino acids and continue synthesis in the same automated run to covalently attach a cell-penetrating peptide (CPP) sequence, creating the PPNA conjugate in a "single-shot" without intermediate cleavage or purification [5].

- Final Cleavage and Analysis: Cleave the final conjugate from the resin using standard TFA cocktail, precipitate, and characterize by HPLC and LC-MS [5].

Synthesis Method Comparison Diagram

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for PNA Synthesis

| Reagent/Material | Function/Purpose | Application Notes |

|---|---|---|

| Fmoc/Bhoc PNA Monomers | Building blocks for chain assembly; Fmoc protects backbone, Bhoc protects nucleobases [11]. | Most common chemistry for automated synthesizers; compatible with peptide synthesisers [11]. |

| Rink Amide Resin (XAL-PEG-PS) | Solid support for synthesis; provides amide terminus upon cleavage [11] [7]. | Universal support for both PNA and peptide synthesis; PEG spacer improves solvation and yield [11]. |

| PyAOP Activator | Peptide coupling reagent forming active esters for amide bond formation [5]. | Used with DIEA base; preferred for efficient coupling in both manual and flow systems [5]. |

| AEEA Linker (eg1) | Spacer molecule incorporated between PNA and peptide sequences [11]. | Crucial for reducing steric hindrance and improving conjugation efficiency and final yield [11]. |

| Cell-Penetrating Peptides (CPPs) | Peptide vectors (e.g., (KFF)3K, TP10) conjugated to PNA to enable cellular uptake [5] [9] [7]. | Covalently attached to PNA to overcome innate poor membrane permeability [9]. |

| Neostenine | Neostenine, MF:C17H27NO2, MW:277.4 g/mol | Chemical Reagent |

| Tenacissoside G | Tenacissoside G, MF:C42H64O14, MW:792.9 g/mol | Chemical Reagent |

The limitations of manual and standard batch methods for PNA synthesis—characterized by excessively long cycle times, low crude purity, limited access to therapeutically relevant longer sequences, and inefficient conjugate production—represent a significant impediment to the advancement of PNA-based therapeutics and research tools. The data and protocols presented herein quantitatively define this synthesis bottleneck. The adoption of fully automated, high-temperature flow synthesis platforms directly addresses these challenges, reducing coupling times from hours to seconds, enabling the single-shot production of complex PNA-peptide conjugates, and providing researchers with a robust and scalable method to accelerate the discovery and development of next-generation PNA agents.

Inside the Automated Flow Synthesizer: Engineering and Workflow for Rapid PPNA Production

Architecture of a Fully Automated Fast-Flow Instrument

The synthesis of complex biomolecules like peptide-PNA conjugates (PPNAs) presents significant challenges in modern therapeutic development, including low yields, long synthesis times, and sequence limitations. Automated fast-flow synthesis technology has emerged as a transformative approach to overcome these hurdles, enabling rapid production of high-purity compounds for drug discovery applications. This technical note details the architecture and operation of a fully automated fast-flow instrument specifically designed for the synthesis of PPNA conjugates, framing this technology within the broader context of an automated platform for peptide-PNA conjugate research. The platform significantly accelerates the development timeline for antisense therapeutics, particularly relevant for rapid response to emerging viral pathogens such as SARS-CoV-2 [21] [5].

Instrument Architecture and Modules

The automated microscale flow synthesizer is constructed from commercially available components and a machined reaction vessel, employing a design philosophy similar to previously reported fast-flow peptide synthesizers [21]. The instrument architecture comprises six or seven interconnected modules that work in concert to enable fully automated synthesis.

Table 1: Core Modules of the Automated Fast-Flow Synthesizer

| Module Number | Module Name | Key Components | Primary Function |

|---|---|---|---|

| 1 | Reagent Storage | Glass containers, nitrogen atmosphere | Storage and preservation of liquid reagents and PNA monomers |

| 2 | Valve System | Two chemically inert multiposition valves | Selection and direction of reagents from storage |

| 3 | Pump System | Two or three HPLC pumps | Precise delivery and metering of reagent streams |

| 4 | Reaction Zone | Heated metal tube, aluminum core, reactor chamber | Housing solid-phase resin and facilitating coupling reactions |

| 5 | In-line Monitoring | UV-Vis detector | Real-time analysis of spent reagent composition |

| 6 | Control System | Computer, Mechwolf programming environment [21] [5] | Coordination and control of all instrument modules |

The synthesis process begins with reagents stored in Module 1. Module 2 valves select the required reagents, which are then pumped (Module 3) to a T-mixer. The combined flow travels through Module 4, where it is preheated in a metal tube before passing through the resin-packed reactor chamber. The solid-phase resin, typically Rink Amide resin with a loading of 0.5 mmol/g, is contained in a removable reactor chamber with a 1 mL volume, designed for a 4.4-7.5 μmol-scale synthesis [21] [5]. Module 5 monitors the process, and Module 6 orchestrates the entire operation via a modular Python script in the Mechwolf environment [21] [5].

The logical workflow of the synthesis process is controlled by a central script that defines the sequence of operations for each module. The relationship between the command script and the instrument's physical response is critical for achieving high-fidelity synthesis.

Performance Data and Optimization

The transition from traditional manual synthesis to automated fast-flow systems has yielded dramatic improvements in synthesis efficiency. The following table quantifies these performance gains.

Table 2: Performance Comparison of PNA Synthesis Methods

| Synthesis Parameter | Manual Batch Synthesis | Automated Fast-Flow Synthesis |

|---|---|---|

| Coupling Time per Amide Bond | ~10 minutes (45°C microwave) [5] to 180 minutes (PMO, room temp) [21] | 10 seconds [5] to 8 minutes (PMO) [21] |

| Total Synthesis Cycle Time | Several hours for a 4-mer [5] | ~3 minutes per cycle [5], ~3.5 hours for a full therapeutic PMO [21] |

| Typical Crude Purity | ~57% for a 4-mer PNA [5] | Up to 92-95% [21] [4] |

| Synthesis Scale | ~100 mg resin [5] | 4.4-7.5 μmol scale (e.g., 15 mg of 0.5 mmol/g resin) [21] [5] |

| Key Enabler | - | High-temperature (70-90°C) flow chemistry [21] |

Optimization of the synthesis process was achieved through iterative changes in flow variables. A major focus was determining the maximum allowable temperature to accelerate reactions without degrading synthetic intermediates. Initial screens at 70°C provided the desired material but with sub-optimal crude purity of 72%. Further optimization of the instrument command recipe, monomer equivalents, and coupling catalysts improved crude purity to 92% [21]. The use of in-line UV-vis monitoring combined with LC-MS and HPLC product characterization was crucial for this rapid optimization, allowing for direct feedback on deprotection efficiency and mass transfer rates [5].

Experimental Protocol: Fully Automated Flow Synthesis of PPNA

Reagent Preparation and Instrument Setup

Research Reagent Solutions and Essential Materials

Table 3: Key Research Reagents and Materials for PPNA Synthesis

| Reagent/Material | Specification/Function |

|---|---|

| PNA Monomers | Fmoc-protected; building blocks for oligomer synthesis. |

| Activator | e.g., PyAOP ((7-Azabenzotriazol-1-yloxy)trispyrrolidinophosphonium hexafluorophosphate); facilitates amide bond formation [5]. |

| Base | e.g., DIEA (N,N-Diisopropylethylamine); acts as a proton scavenger [5]. |

| Deprotection Solution | Piperidine in DMF; removes the Fmoc protecting group [5]. |

| Solid Support | Rink Amide Resin (0.5 mmol/g loading); provides the solid phase for chain elongation [5]. |

| Solvent | Anhydrous DMF (Dimethylformamide); primary solvent for reagents. |

- Resin Loading: Load 15 mg of Rink Amide resin (0.5 mmol/g loading) into the removable reactor chamber. This establishes a 7.5 μmol scale synthesis [5].

- Reagent Preparation: Prepare and load all reagent solutions into the designated glass containers in Module 1 under a nitrogen atmosphere:

- System Initialization: Power on the HPLC pumps (Module 3), heating elements for the reaction zone (Module 4), and the UV-vis detector (Module 5). Initialize the control computer (Module 6) and load the synthesis script.

Synthesis Execution and Cyclic Operation

The following workflow details a single synthesis cycle for the addition of one PNA monomer. This cycle is repeated iteratively for each base in the target sequence.

Fmoc Deprotection

- Action: The control script activates the valve (Module 2) to select the deprotection solution (piperidine in DMF). The HPLC pump (Module 3) delivers the solution through the reaction zone (Module 4). For high-temperature synthesis, the piperidine solution may flow through a room-temperature loop before meeting the preheated reactor to create an optimal ~40°C deprotection environment [5].

- Purpose: Removes the Fmoc (fluorenylmethyloxycarbonyl) protecting group from the terminal amine of the growing PNA chain, enabling the next coupling reaction.

- Monitoring: The UV-vis detector (Module 5) monitors the characteristic absorbance of the removed Fmoc group, providing data on deprotection efficiency [5].

Washing

- Action: The system switches to deliver a wash solvent (e.g., DMF) to flush the reactor and resin bed clean of the deprotection solution and by-products. A wash volume of at least 1.6 mL (20 pump strokes) is typically used to ensure complete clearance [21].

Monomer Coupling

- Action: The valve system (Module 2) simultaneously selects the streams for the PNA monomer, activator (e.g., PyAOP), and base (e.g., DIEA). The three HPLC pumps (Module 3) deliver these reagents, which are merged at a T-mixer. The mixture flows through a preheater, forming an activated ester, and then through the resin-packed reactor chamber maintained at high temperature (70-90°C) [21] [5].

- Critical Parameters: The coupling reaction is completed in as little as 10 seconds per amide bond at a flow rate of 2.5 mL/min [5]. The high temperature is a key factor in achieving this dramatic rate enhancement.

Washing

- Action: The system performs another wash cycle with an appropriate solvent to remove excess monomer and coupling reagents from the resin bed.

Cycle Repetition and Completion

- Steps 1-4 constitute one coupling cycle and are repeated automatically for each monomer in the target PNA sequence.

- Peptide Conjugation (for PPNAs): Following PNA chain assembly, a cell-penetrating peptide (CPP) can be synthesized directly on the PNA chain in a "single-shot" process using the same instrument and coupling protocol, without intermediate cleavage [5].

- Final Cleavage: Once the full sequence is assembled, the flow of a cleavage cocktail (e.g., Trifluoroacetic acid-based solutions) through the reactor severs the completed PPNA from the solid support and removes any remaining protecting groups, yielding the crude product in solution.

Post-Synthesis Analysis

- Product Analysis: Analyze the crude product using Liquid Chromatography-Mass Spectrometry (LC-MS) and High-Performance Liquid Chromatography (HPLC) to determine purity and identity. The optimized flow synthesis protocol achieves crude purities of up to 92-95% for target sequences [21] [4].

- Bioactivity Testing: For therapeutic candidates, perform relevant biological assays. For example, anti-SARS-CoV-2 PPNAs synthesized with this technology have been evaluated in live virus infection assays, demonstrating over 95% reduction in viral titer [5].

The fully automated fast-flow synthesizer represents a significant advancement in the architecture for biomolecule synthesis. Its modular design, integration of high-temperature flow chemistry, and comprehensive computer control enable the rapid and efficient production of challenging molecules like peptide-PNA conjugates. This platform reduces synthesis times from days to hours, provides high crude purity, and facilitates the direct "single-shot" synthesis of complex conjugates. By automating and accelerating the construction of these potential therapeutics, this technology serves as a powerful tool in an automated peptide-PNA research platform, significantly accelerating the drug discovery pipeline for applications from genetic diseases to antiviral agents.

Within the field of peptide-peptide nucleic acid (PNA) conjugate research, the synthesis of these complex molecules has been a significant bottleneck. Traditional solid-phase synthesis methods are time-consuming, often requiring 60 to 100 minutes to incorporate a single amino acid residue [22]. This technical limitation has severely restricted the rapid investigation and development of PNA-based therapeutics, including antisense agents for applications such as antiviral and anticancer therapies [5]. However, recent advances in automated flow chemistry have revolutionized this landscape, enabling the formation of amide bonds in as little as 10 seconds under optimized high-temperature conditions [5]. This application note details the protocols and quantitative data supporting this transformative methodology, providing researchers with the tools to implement accelerated synthesis within their automated platforms for peptide-PNA conjugate production.

Key Principles and Quantitative Performance Data

The foundation of ultra-rapid amide bond formation lies in the precise application of elevated temperature and continuous flow dynamics. At room temperature, amide bond formation using activated amino acid solutions is already rapid, with a reaction half-life of approximately 4.6 seconds [22]. The application of high-temperature flow chemistry intensifies this process dramatically; at 60°C, amide bond formation is complete in less than 10 seconds, and Fmoc removal occurs in less than 20 seconds [22]. Further optimization has demonstrated that a temperature of 70°C is optimal for PNA synthesis specifically, enabling each amide bond to be formed in precisely 10 seconds [5]. This represents an order-of-magnitude acceleration compared to commercial microwave synthesizers (10 minutes/amide bond) or traditional DNA synthesizers (32 minutes/coupling cycle) [5].

Table 1: Comparative Performance of Amide Bond Formation Methodologies

| Synthesis Method | Temperature | Time per Amide Bond | Relative Speed |

|---|---|---|---|

| Traditional Fmoc SPPS [22] | Room Temperature | 60-100 minutes | 1x |

| Microwave-Assisted SPPS [5] | 45°C | 20 minutes | 3-5x |

| Early Flow-Based SPPS [22] | 60°C | 12 minutes | 5-8x |

| High-Temperature Flow Chemistry (PNA) [5] | 70°C | 10 seconds | 360-600x |

The accelerated kinetics are not solely temperature-dependent. Flow-based systems maintain a maximal concentration of reagents in the reaction vessel, quickly exchange reagents, and eliminate the time needed to heat reagents after they have been added to the vessel [22]. This integrated approach of high temperature and optimized fluidics enables the complete solid-phase PNA synthesis cycle, including washing and deprotection steps, to be accomplished within 3 minutes per monomer [5].

Table 2: Impact of High-Temperature Flow Synthesis on Complete PNA Production

| Metric | Traditional Synthesis | High-Temperature Flow | Improvement |

|---|---|---|---|

| Cycle Time per Residue | ~90 minutes [22] | ~3 minutes [5] | 30x faster |

| Synthesis Time for 18-mer PPNA | ~27 hours | ~54 minutes | 30x faster |

| Daily Output (Theoretical) | <1 complete PPNAs | 8 anti-SARS-CoV-2 PPNAs [5] | 8x higher throughput |

| Crude Purity (Exemplary 4-mer) | 57% [5] | 70% [5] | Significant enhancement |

Experimental Protocols

Automated Flow Synthesis Apparatus Configuration

The automated flow platform for high-speed PNA synthesis consists of an integrated system with specific components that work in concert to achieve the rapid amide bond formation.

Step-by-Step Synthesis Protocol

Protocol: Automated High-Temperature Flow Synthesis of PNA-Peptide Conjugates

Materials and Equipment:

- Automated flow synthesizer (e.g., iChemAFS platform or equivalent) [4] [5]

- Rink Amide resin (0.5 mmol/g loading) [5]

- Fmoc/Bhoc protected PNA monomers

- Activator: PyAOP or HATU/HBTU

- Base: DIEA (N,N-Diisopropylethylamine)

- Deprotection reagent: 50% (v/v) piperidine in DMF

- Anhydrous DMF solvent

Procedure:

Reactor Setup

- Load 15 mg of Rink Amide resin (0.5 mmol/g) into the custom reactor designed for 7.5 μmol scale synthesis [5].

- Ensure the reactor is properly packed to create a packed bed with low backpressure.

System Pre-conditioning

- Pre-heat the entire system, including the heat exchanger and reactor, to the target temperature of 70°C [5].

- Purge all fluidic pathways with anhydrous DMF to eliminate moisture and ensure solvent compatibility.

Coupling Cycle (10 seconds per amide bond)

- Prepare the coupling solution containing 10 equivalents of PNA monomer, 9.6 equivalents of activator (PyAOP), and 30 equivalents of DIEA base in anhydrous DMF [5].

- Deliver the coupling solution through the pre-heat loop (70°C) at a flow rate of 2.5 mL/min.

- Pass the activated monomer through the heated reactor (70°C) for precisely 10 seconds to complete amide bond formation [5].

- Monitor the process using in-line UV-vis detection to verify reagent delivery.

Washing Step

- Wash the resin with 20 mL of DMF delivered over 2 minutes at a flow rate of 10 mL/min [22].

- Ensure complete removal of excess coupling reagents before proceeding to deprotection.

Fmoc Deprotection

- Deliver 50% (v/v) piperidine in DMF through a room temperature loop, which then meets the 70°C reactor to create an approximate 40°C environment [5].

- Maintain deprotection conditions for the optimized time (determined empirically, typically 30-60 seconds).

- Monitor the deprotection efficiency via UV absorbance at 304 nm, tracking the formation of the dibenzofulvene-piperidine adduct [22] [5].

Repeat Cycle

- Repeat steps 3-5 for each additional monomer in the sequence.

- For peptide-PNA conjugates (PPNAs), continue synthesis seamlessly by switching to Fmoc-protected amino acids after completing the PNA sequence [5].

Cleavage and Purification

The Scientist's Toolkit: Essential Research Reagents

Successful implementation of high-temperature flow synthesis for PNA conjugates requires specific reagents and materials optimized for these accelerated conditions.

Table 3: Essential Research Reagent Solutions for High-Temperature PNA Flow Synthesis

| Reagent/Material | Function | Optimized Concentration/Type | Notes |

|---|---|---|---|

| PNA Monomers | Building blocks for PNA synthesis | Fmoc/Bhoc protected [7] | Bhoc protection of nucleobases prevents side reactions during synthesis |

| Activator | Activates carboxylic acid for amide coupling | PyAOP, HATU, or HBTU [5] | 9.6 equivalents relative to monomer; PyAOP particularly effective for PNA |

| Base | Facilitates activation and coupling | DIEA (N,N-Diisopropylethylamine) [5] | 30 equivalents in DMF; critical for maintaining coupling efficiency |

| Deprotection Reagent | Removes Fmoc protecting group | 50% (v/v) piperidine in DMF [22] [5] | Higher concentration than standard 20% for faster deprotection at elevated temperature |

| Solid Support | Platform for solid-phase synthesis | Rink Amide resin (0.5 mmol/g) [5] | Higher loading resin (0.5 mmol/g) enables microscale synthesis (7.5 μmol) |

| Coupling Solvent | Reaction medium | Anhydrous DMF [5] | Must be rigorously anhydrous to prevent premature hydrolysis of activated esters |

| DAN Linker | Enables on-resin cyclization | Diaminonicotinic acid (DAN) [4] [6] | Critical for head-to-tail cyclization of cyclic peptide-PNA conjugates |

| AT1R antagonist 3 | AT1R antagonist 3, MF:C22H16N6O2S, MW:428.5 g/mol | Chemical Reagent | Bench Chemicals |

| Coenzyme FO | Coenzyme FO, MF:C16H17N3O7, MW:363.32 g/mol | Chemical Reagent | Bench Chemicals |

Applications and Case Studies

The implementation of this high-temperature flow synthesis platform has enabled significant advances in PNA research and therapeutic development. A primary demonstration involved the synthesis of an 18-mer PPNA targeting the β-thalassemia gene sequence (IVS2-654) conjugated to a 12-mer cell-penetrating peptide in a single, automated operation [5]. The resulting conjugate exhibited threefold higher activity in splice-correction assays compared to transfected PNA, demonstrating that the rapid synthesis method produces biologically active molecules [5].

Perhaps the most compelling validation of the platform's throughput came during the SARS-CoV-2 pandemic, when researchers synthesized eight different anti-SARS-CoV-2 PPNAs in a single day [5]. One of these conjugates, targeting the 5' untranslated region of the SARS-CoV-2 genomic RNA, reduced viral titer by over 95% in live virus infection assays (IC₅₀ = 0.8 μM) [5] [23]. This case study highlights how the accelerated synthesis capability enables rapid response to emerging health threats by facilitating the quick production and screening of multiple therapeutic candidates.

Beyond linear conjugates, the methodology has been extended to cyclic peptide-PNA conjugates using an automated on-resin head-to-tail cyclization strategy with a diaminonicotinic acid (DAN) linker [4] [6]. This approach has achieved 2- to 12-residue cyclic sequences with up to 95% crude purity and has been used to construct libraries of 22 PNA/PPNA structures for membrane permeability screening [4]. The technology has also been applied to synthesize cyclic PPNA nanotubes with high aspect ratios, characterized by TEM and AFM, demonstrating applications in nanotechnology as well as biomedicine [4] [6].

The development of antisense oligonucleotide-based therapeutics represents a rapidly advancing frontier in biomedical science, particularly for treating genetic, viral, and acquired diseases [5]. Among these emerging biologics, peptide nucleic acids (PNAs) offer unique advantages due to their charge-neutral pseudopeptide backbone, which confers superior binding affinity and enzymatic stability compared to natural nucleic acids [5]. However, the clinical translation of PNAs has been hampered by challenges including poor cellular uptake, limited solubility, and rapid elimination [5]. While conjugation to cell-penetrating peptides (CPPs) can mitigate these limitations, the synthesis of these complex conjugates—particularly longer PNA sequences (>15-mer)—remains inefficient using conventional methods [5].

Traditional batch synthesis approaches often struggle with on-resin aggregation, deletion sequences, and various side reactions, making robust production of long PNA sequences difficult [5]. The established workaround of stepwise synthesis via click chemistry adds complexity and reduces overall efficiency [5]. This application note details a transformative fully automated fast-flow synthesis platform that enables single-shot manufacturing of CPP-PNA conjugates (PPNAs) with dramatically improved speed and purity, effectively overcoming previous synthetic limitations and accelerating therapeutic development.

Automated Fast-Flow Synthesis Platform

Instrument Design and Workflow

The automated flow PNA synthesizer represents a significant engineering advancement, comprising seven integrated modules: a central control computer, solution storage system, three HPLC pumps, three multiposition valves, heating elements, reaction zone, and an in-line UV–vis detector [5]. The system operates under the control of a modular script in the Mechwolf programming environment, coordinating all synthetic processes with precision [5].

During the coupling reaction, three HPLC pumps simultaneously draw reagents (PNA monomer, activator, and base solutions) from nitrogen-purged storage reservoirs [5]. These solutions merge via a valve assembly and pass through a 70°C heating module, where the PNA monomer rapidly forms an activated ester. This activated species then flows through the reaction zone—a packed bed of solid-phase resin maintained at 70°C—where amide bond formation completes within merely 10 seconds [5]. The deprotection step utilizes a temperature-gradient approach, with piperidine solution flowing through a room temperature loop before meeting the 70°C reactor to create an optimal ~40°C deprotection environment that minimizes nucleobase adduct formation [5].

The synthesizer employs a reusable reactor body designed for 7.5 μmol scale synthesis, typically loaded with 15 mg of 0.5 mmol/g Rink Amide resin [5]. This microscale approach significantly reduces expensive monomer consumption while yielding sufficient product (milligrams) for comprehensive biological characterization. The complete synthetic cycle for each amide bond formation requires approximately 3 minutes, representing a substantial improvement over conventional methods [5].

The following workflow diagram illustrates the automated synthesis process:

Synthesis Optimization and Efficiency

Extensive optimization efforts have established the superior performance of the automated flow synthesis platform compared to manual methods. The evaluation of reaction conditions revealed significant improvements in crude purity and reduction of side products [5].

Table 1: Optimization of Automated Flow PNA Synthesis Conditions

| Entry | Synthesis Method | Temperature | Deprotection Base | Crude Purity | Major Side Products |

|---|---|---|---|---|---|

| 1 | Manual | ~25°C | Piperidine | 57% | ~15% isomers, ~4% deletions, ~2% nucleobase adducts |

| 2 | Automated Flow | 70°C | Piperidine | 70% | ~10% deletions, ~7% nucleobase adducts |

| 3 | Automated Flow | 70°C | Piperazine | <60% | Increased deletion sequences |

| 4 | Automated Flow | 70°C | Morpholine | <60% | Increased deletion sequences |

Note: PNA sequence ACTG-Gly-CONHâ‚‚ used for optimization study. Automated conditions: 15 mg Rink Amide resin (0.5 mmol/g), 10 equiv PNA monomer, 9.6 equiv activator, 30 equiv DIEA in DMF, flow rate: 2.5 mL/min. Crude purity determined by HPLC UV absorbance at 280 nm [5].

The high-temperature (70°C) flow conditions significantly accelerate amide bond formation while reducing on-resin aggregation—a major limitation in traditional PNA synthesis [5]. Through systematic screening of deprotection bases, piperidine was identified as optimal for Fmoc-removal at elevated temperatures [5]. A key focus during optimization was preventing piperidine adduct formation during deprotection steps, which was achieved through precise temperature control in the reaction zone [5].

Research Reagent Solutions

The successful implementation of single-shot PPNA synthesis requires specific high-quality reagents and materials. The following table details essential components for establishing this automated platform in a research setting.

Table 2: Essential Research Reagents for Automated PPNA Synthesis

| Reagent/Material | Function/Application | Specifications/Notes |

|---|---|---|

| Rink Amide Resin | Solid support for synthesis | 0.5 mmol/g loading capacity; 15 mg per 7.5 μmol synthesis [5] |

| PNA Monomers | Building blocks for chain elongation | N-(2-aminoethyl)glycine backbone with nucleobase attachments; 10 equivalents per coupling [5] |

| PyAOP Activator | Amide bond formation | (7-Azabenzotriazol-1-yloxy)trispyrrolidinophosphonium hexafluorophosphate; 9.6 equivalents per coupling [5] |

| DIEA Base | Coupling reaction base | N,N-Diisopropylethylamine; 30 equivalents in DMF [5] |

| Piperidine Solution | Fmoc-deprotection | 20-30% in DMF; optimized for high-temperature deprotection [5] |

| DMF Solvent | Primary reaction solvent | Anhydrous, amine-free quality for optimal coupling efficiency [5] |

| Cell-Penetrating Peptides | Conjugation for enhanced delivery | Covalently attached to PNA; improves cellular uptake and solubility [5] |

Experimental Protocols

Single-Shot PPNA Synthesis Protocol

Objective: To synthesize CPP-conjugated PNAs (PPNAs) in a single, fully automated process using fast-flow technology.

Materials Preparation:

- Resin Preparation: Load 15 mg of Rink Amide resin (0.5 mmol/g capacity) into the reusable reactor body [5].

- Reagent Preparation: Transfer the following solutions to nitrogen-purged reservoirs:

- PNA monomer solutions: 100 mM in DMF (10 equivalents per coupling)

- Activator solution: 96 mM PyAOP in DMF (9.6 equivalents per coupling)

- Base solution: 300 mM DIEA in DMF (30 equivalents per coupling)

- Deprotection solution: 30% (v/v) piperidine in DMF [5]

- System Priming: Prime all fluidic pathways with appropriate solvents, ensuring bubble-free operation.

Synthetic Procedure:

- Initialization: Initiate the Mechwolf control script to begin the automated synthesis sequence [5].

- Deprotection Cycle: Flow piperidine solution through the resin bed at ~40°C for efficient Fmoc removal (monitored via in-line UV-vis at 280 nm) [5].

- Washing: Flush the system with DMF to remove deprotection byproducts completely.

- Coupling Cycle: Simultaneously pump PNA monomer, activator, and base solutions through the 70°C heating module, then through the 70°C reactor for amide bond formation (10 seconds per coupling) [5].

- Repetition: Repeat steps 2-4 for each monomer addition in the target sequence.

- CPP Conjugation: Following PNA chain assembly, proceed with CPP coupling using the same optimized conditions without intermediate cleavage.

- Cleavage and Deprotection: Upon sequence completion, cleave the finished PPNA from the resin using standard TFA-based cocktails.

- Purification: Purify crude products via reversed-phase HPLC and verify by LC-MS analysis.

Critical Parameters:

- Maintain precise temperature control (70°C for coupling, ~40°C for deprotection)

- Ensure complete dissolution of all reagents in high-purity DMF

- Monitor UV chromatograms for consistent Fmoc-removal efficiency throughout synthesis

- Maintain nitrogen atmosphere over reagent solutions to prevent degradation

PPNA Solubilization and Handling

Following synthesis, proper handling of PPNA products is essential for maintaining stability and functionality:

- Reconstitution: Dissolve purified PPNA oligomers in pure deionized water. For difficult sequences, heat the aqueous solution to 60°C for 10 minutes to improve solubility [24].

- Alternative Solvents: If water alone proves insufficient, add 0.1% TFA or 10-20% acetonitrile to the aqueous solution. For particularly challenging cases, DMF or NMP may be used, though these should be avoided if the PNA is intended for PCR applications [24].

- Storage: Prepare stock solutions at 0.1-1 mM concentrations in appropriate solvents, aliquot, and store at -20°C for long-term preservation.

Applications and Biological Validation

The utility of single-shot synthesized PPNAs has been demonstrated across multiple biological applications, establishing this platform as a robust method for producing therapeutically relevant oligonucleotides.

Splice-Correction Application

A synthesized 18-mer PPNA targeting the β-thalassemia IVS2-654 gene sequence displayed threefold enhanced activity compared to transfected unmodified PNA in a splice-correction assay using an enhanced green fluorescence protein (EGFP) reporter system [5]. This demonstrates the significant biological advantage conferred by the CPP conjugation and optimized synthesis.

Experimental Protocol for Splice-Correction Assay:

- Cell Culture: Maintain HeLa pLuc705 cells (which harbor an aberrantly spliced luciferase gene) under standard conditions.

- Transfection: Seed cells in 24-well plates at appropriate density and incubate for 24 hours.

- PPNA Treatment: Apply single-shot synthesized PPNA (1-10 μM range) using commercial transfection reagents or via direct uptake.

- Incubation: Continue culture for 24-48 hours to allow splice correction.

- Analysis: Harvest cells and measure luciferase activity using standard luminescence assays. Normalize data to protein content or control transfection.

Antiviral Application Against SARS-CoV-2

The platform's capability for rapid therapeutic development was demonstrated through the synthesis of eight anti-SARS-CoV-2 PPNAs within a single day [5]. From this library, a PPNA targeting the 5' untranslated region (5'UTR) of SARS-CoV-2 genomic RNA achieved over 95% reduction in viral titer (IC₅₀ = 0.8 μM) in live virus infection assays [5].

Experimental Protocol for Antiviral Assessment:

- Virus and Cells: Culture Vero E6 cells and maintain SARS-CoV-2 virus stocks under appropriate biosafety containment.

- Infection Model: Pre-treat cells with PPNA (0.1-10 μM range) for 4-6 hours before infection with SARS-CoV-2 at low MOI.

- Post-Infection: Maintain PPNA in medium throughout the infection period.

- Viral Titer Quantification: At 48 hours post-infection, collect supernatants and quantify viral titers by plaque assay or TCIDâ‚…â‚€.

- Cytotoxicity Assessment: Perform parallel MTT or similar assays to confirm PPNA treatments do not affect cell viability at active concentrations.

The following diagram illustrates the therapeutic mechanism of antisense PPNAs against viral targets:

Comparative Performance Data

The automated flow synthesis platform demonstrates remarkable efficiency gains compared to conventional methods, as quantified through direct comparison of synthesis metrics and biological outcomes.

Table 3: Performance Comparison of PNA Synthesis Technologies

| Parameter | Manual Batch Synthesis | Commercial Microwave Synthesizer | Automated Fast-Flow Platform |

|---|---|---|---|

| Coupling Time per Amide Bond | ~4 hours for 4-mer [5] | 10 minutes [5] | 10 seconds [5] |

| Typical Crude Purity (15-mer) | ~57% (4-mer) [5] | Not specified | >70% [5] |

| Long Sequence Capability | Challenging (>15-mer) [5] | Limited | Enabled (>15-mer) [5] |

| CPP Conjugation Approach | Stepwise via click chemistry [5] | Stepwise | Single-shot direct synthesis [5] |

| Library Production Time | Days-Weeks | Days | 8 PPNAs in 1 day [5] |

| Biological Activity | Baseline | Not specified | 3-fold enhancement over transfected PNA [5] |

Platform Extensions: Cyclic PNA Synthesis

The automated flow synthesis approach has been successfully extended to cyclic PNA and PPNA structures, which offer enhanced nuclease resistance and binding affinity [4]. Using an automated on-resin head-to-tail cyclization strategy with a diaminonicotinic acid (DAN) linker, researchers have achieved 2- to 12-residue cyclic sequences with up to 95% crude purity [4]. This methodology supports extensive functionalization with natural and non-natural amino acids, enabling construction of diverse libraries for drug discovery and nanotechnology applications [4].

A library of 22 cyclic PNA/PPNA structures has been successfully synthesized and screened for membrane permeability using parallel artificial membrane permeability assays (PAMPA), demonstrating the platform's utility in structure-activity relationship studies [4]. Additionally, the synthesis of cyclic PPNA nanotubes with high aspect ratios highlights the material science applications enabled by this versatile technology [4].

Peptide Nucleic Acids (PNAs) are synthetic oligonucleotide analogues featuring a neutral N-(2-aminoethyl)glycine backbone that confers superior binding affinity, nuclease resistance, and enzymatic stability compared to natural nucleic acids [5] [25] [7]. The conjugation of PNAs with various functional moieties, particularly cell-penetrating peptides (CPPs), creates multifunctional hybrids that overcome inherent limitations of native PNAs, including poor cellular uptake and limited aqueous solubility [5] [26] [7]. Automated synthesis platforms, especially those utilizing fast-flow technology, have revolutionized the production of these conjugates, enabling rapid exploration of their applications across antiviral therapy, antimicrobial interventions, and advanced nanomaterials [5] [27]. This document provides detailed application notes and experimental protocols for leveraging peptide-PNA conjugates (PPNAs) in these diverse research domains.

The following tables summarize key quantitative data demonstrating the efficacy of PNA conjugates across various applications, providing researchers with benchmark performance metrics.

Table 1: Antiviral Efficacy of Selected PNA Conjugates

| Target Virus | PNA Conjugate Type | Target Genomic Region | Efficacy (Viral Titer Reduction/ICâ‚…â‚€) | Citation |

|---|---|---|---|---|