Automated Flow Chemistry Platforms: Accelerating Drug Discovery and Synthesis

This article explores the transformative role of automated flow chemistry platforms in modern chemical synthesis, particularly for drug discovery and development.

Automated Flow Chemistry Platforms: Accelerating Drug Discovery and Synthesis

Abstract

This article explores the transformative role of automated flow chemistry platforms in modern chemical synthesis, particularly for drug discovery and development. It provides a comprehensive examination of the core principles, from foundational concepts like 'transformers' and 'generators' to advanced applications in high-throughput experimentation and multi-step synthesis. The content delves into practical methodologies for troubleshooting and optimizing reactions, including the use of AI and machine learning for closed-loop systems. Furthermore, it offers a comparative analysis of the capabilities and limitations of flow versus traditional batch chemistry, highlighting real-world validation through case studies in pharmaceutical manufacturing. This resource is tailored for researchers, scientists, and development professionals seeking to leverage automation for more efficient, safe, and reproducible chemical synthesis.

Flow Chemistry Fundamentals: Core Principles and System Architecture

Defining Flow Chemistry: A Paradigm Shift from Traditional Batch Processing

The field of chemical synthesis is undergoing a profound transformation, catalyzed by the shift from traditional batch processing to continuous flow chemistry. This paradigm shift represents a fundamental rethinking of how chemical reactions are performed, moving away from the centuries-old practice of carrying out reactions in sequential batches within round-bottomed flasks toward a continuous, automated process where reactants are pumped through tubular reactors [1] [2] [3]. Flow chemistry offers enhanced control over reaction parameters, improved safety profiles for hazardous reactions, and more efficient scaling from laboratory research to industrial production [2] [4]. The global flow chemistry market, valued at $70.7 million in 2024 and projected to reach $160 million by 2032, reflects the growing recognition of these advantages across pharmaceutical, fine chemical, and materials science sectors [3]. This article delineates the core principles of flow chemistry, provides a structured comparison with batch methodologies, and presents detailed application notes and protocols to empower researchers in harnessing this transformative technology for automated synthesis research.

Fundamental Principles and Comparative Analysis

Core Definitions and Operating Principles

Flow Chemistry is defined as a manufacturing technique where chemical reactions are performed in a continuously flowing stream within confined channels or tubular reactors. In this system, two or more fluid reagents are precisely pumped through a reactor, where they mix and react under carefully controlled thermal and pressure conditions [3]. The product streams out continuously at the outlet, with the overall output volume limited only by operational time [5].

In contrast, Traditional Batch Processing involves charging a reactor with reactants, allowing the reaction to proceed to completion, then emptying, cleaning, and repeating the cycle for subsequent batches. This process is limited by the volume of the reaction vessel and involves significant downtime between operations [2] [5].

Comparative Advantages: Flow vs. Batch Chemistry

Table 1: Comprehensive Comparison of Flow and Batch Chemistry Attributes

| Attribute | Flow Chemistry | Batch Chemistry |

|---|---|---|

| Process Nature | Continuous process | Sequential discrete batches |

| Scale Limitations | Limited only by operation time | Limited by vessel volume |

| Heat & Mass Transfer | Superior due to high surface-to-volume ratio [6] [2] | Limited by vessel geometry and mixing efficiency |

| Reaction Control | Precise control of residence time, temperature, and pressure [6] [2] | Less precise, gradients can form |

| Safety Profile | Enhanced safety through small reaction volume at any time [6] [5] | Larger volumes pose greater risk |

| Scalability | Easier scale-up without re-optimization [1] [4] | Often requires extensive re-optimization |

| Automation Potential | High, readily integrated with automation and PAT [1] [7] | Limited for multi-step sequences |

| Handling Solids | Challenging, potential for clogging [5] | Excellent, well-established protocols |

| Photochemistry | Excellent due to uniform light penetration in narrow channels [6] [5] | Limited by light penetration depth |

| Initial Setup | Generally more complex | Simpler, more familiar |

The enhanced mass and heat transfer capabilities in flow systems stem from the high surface-area-to-volume ratio of microreactors, which provides more efficient thermal management and mixing compared to batch reactors [6] [2]. This is particularly valuable for exothermic reactions where heat buildup poses safety concerns. Furthermore, the ability to pressurize flow systems enables the use of solvents at temperatures significantly above their atmospheric boiling points, substantially expanding the available reaction windows [6].

Applications in Automated Synthesis and Drug Discovery

High-Throughput Experimentation and Reaction Screening

Flow chemistry has emerged as a powerful tool for high-throughput experimentation (HTE), enabling rapid screening of reaction parameters and conditions [6]. When combined with automation, flow systems significantly accelerate optimization processes, allowing researchers to efficiently identify optimal parameters for target reactions [2]. This approach is particularly valuable for exploring continuous variables such as residence time, temperature, and stoichiometry, which are challenging to investigate systematically in batch-based HTE platforms [6].

The integration of Process Analytical Technology (PAT) with inline sensors (e.g., UV-VIS, IR, NIR) enables real-time reaction monitoring, forming the basis for closed-loop feedback systems that can automatically adjust process conditions to optimize reaction outcomes [2]. This capability is transforming how researchers approach reaction development and optimization.

Pharmaceutical Synthesis and Compound Library Generation

Flow chemistry is making substantial impacts in drug discovery programs, particularly in the generation of compound libraries for biological screening [1] [4]. The technology addresses critical challenges in early drug discovery by enabling efficient serial library generation and rapid exploration of diverse chemical space [4]. Automated flow platforms facilitate the integration of chemical synthesis with purification and analysis, ensuring a constant and rapid supply of pure compounds ready for biological testing [4].

Specific benefits for drug discovery include:

- Access to challenging chemistry that is restricted or impossible with traditional batch techniques

- Improved safety profiles through in-situ creation of reactive intermediates and handling of hazardous reagents

- Efficient scale-up where reactions optimized on small scale can be directly scaled without re-optimization

- Multi-step synthesis using modular approaches that enable direct synthesis of complex molecules [4]

Advanced Reaction Modalities in Flow Systems

Flow chemistry platforms provide exceptional capabilities for harnessing specialized activation methods that are challenging to implement in batch systems:

Photochemistry: Flow reactors minimize light path length and enable precise control of irradiation time, addressing the fundamental limitations of batch photochemistry where poor light penetration and non-uniform irradiation lead to suboptimal selectivities and conversions [6]. Commercially available and bespoke photochemical flow reactors have been successfully implemented for various transformations [6] [5].

Electrochemistry: The precise control of residence time and electrode positioning in flow electrochemical reactors enables improved selectivity and efficiency compared to batch electrochemical cells [1] [4].

Multi-Step Synthesis: Integrated flow systems allow for the telescoping of multiple reaction steps, including in-line separations and purifications, enabling complex multi-step syntheses in a continuous operation [7] [8]. This capability is particularly valuable for pharmaceutical synthesis where intermediates may be unstable or hazardous.

Experimental Protocols

Protocol 1: High-Throughput Screening and Optimization of Photoredox Fluorodecarboxylation

This protocol adapts and expands upon the methodology reported by Jerkovic et al. for the flavin-catalyzed photoredox fluorodecarboxylation reaction [6].

Research Reagent Solutions and Materials

Table 2: Essential Research Reagents and Equipment

| Item | Function/Application |

|---|---|

| Flow Photoreactor (e.g., Vapourtec UV150 or equivalent) | Provides controlled irradiation for photochemical transformations [6] |

| Precision HPLC/Syringe Pumps | Delivers precise, pulse-free flow of reagents |

| Temperature-Controlled Microreactor | Maintains precise reaction temperature |

| Back Pressure Regulator (BPR) | Maintains system pressure, prevents degassing |

| In-line Analytical Module (e.g., FlowIR, UV) | Enables real-time reaction monitoring |

| Carboxylic Acid Substrate Solution (0.1-0.5 M in anhydrous solvent) | Reactant stream |

| Flavin Photocatalyst Solution (1-5 mol% in anhydrous solvent) | Photoredox catalyst |

| Fluorinating Agent Solution (e.g., Selectfluor, 1.0-2.0 equiv) | Source of electrophilic fluorine |

| Base Solution (e.g., K₂CO₃, 2.0-3.0 equiv) | Promotes substrate decarboxylation |

| Anhydrous Acetonitrile | Reaction solvent |

Step-by-Step Procedure

Reagent Preparation: Prepare separate solutions of the carboxylic acid substrate (0.2 M), flavin photocatalyst (2 mol%), Selectfluor (1.5 equity), and base (2.5 equity) in anhydrous acetonitrile. Ensure complete dissolution and degas if necessary.

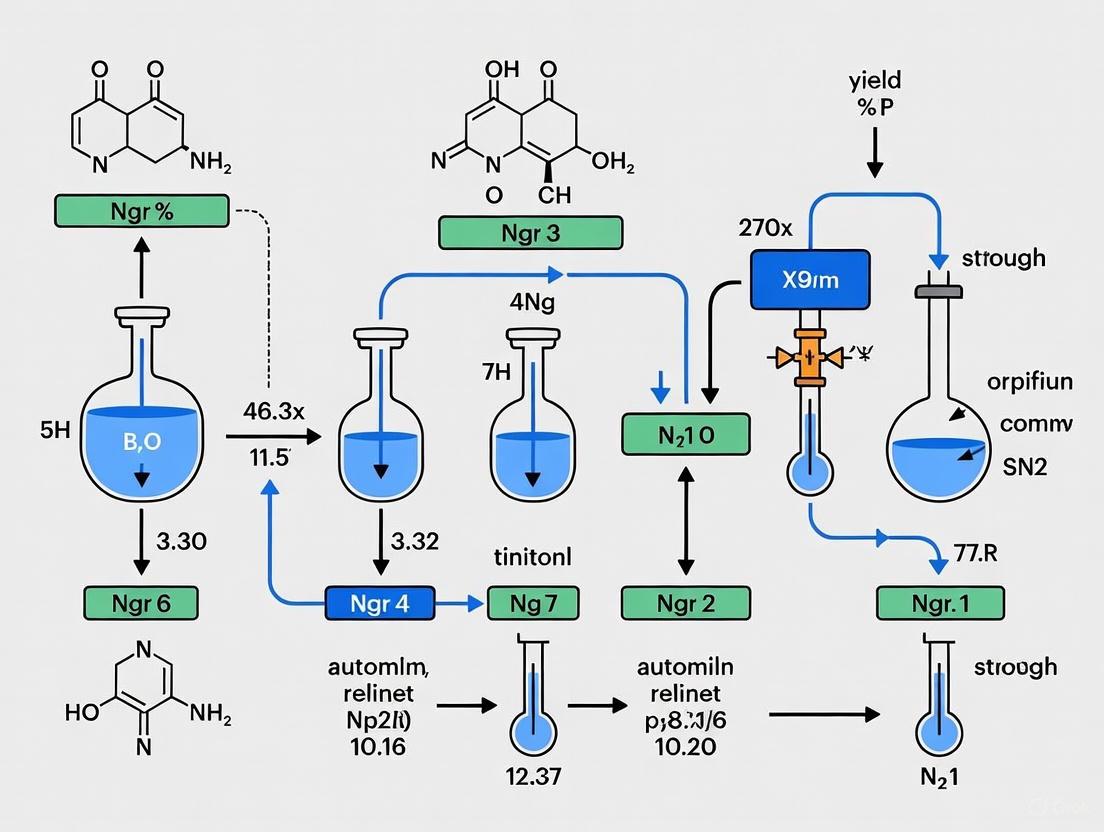

System Configuration and Priming: Configure the flow system for a two-feed approach as illustrated in Figure 1. Connect Feed A (substrate, photocatalyst, and base) and Feed B (fluorinating agent) to their respective pumps. Prime all fluidic paths with solvent to eliminate air and ensure homogeneous mixing.

Initial Screening Conditions: Set the system to initial screening conditions: combine Feed A and Feed B using a T-mixer, direct the combined stream through the photochemical reactor (equipped with 365-400 nm LEDs), maintain residence time of 5-10 minutes, set reactor temperature to 25°C, and apply back pressure of 50-100 psi using the BPR.

High-Throughput Parameter Screening: Implement a Design of Experiments (DoE) approach to systematically vary critical parameters:

- Residence time: 2-20 minutes

- Reaction temperature: 20-60°C

- Catalyst loading: 1-5 mol%

- Stoichiometry of fluorinating agent: 1.0-2.0 equity

Real-Time Monitoring and Analysis: Utilize in-line PAT (e.g., FlowIR, UV-Vis) to monitor reaction progress and conversion. Collect fractions corresponding to different conditions for off-line validation by NMR and LC-MS.

Process Intensification: Once optimal conditions are identified, progressively increase flow rate to reduce residence time while maintaining high conversion. For scale-up, run the optimized process continuously to accumulate product.

Work-up and Isolation: Direct the output stream into a collection vessel containing aqueous quenching solution. For multi-gram production, consider in-line liquid-liquid separation. Concentrate the organic phase and purify by flash chromatography or recrystallization.

Experimental Workflow Visualization

Protocol 2: Automated Multi-Step Synthesis of Pharmaceuticals

This protocol outlines a generalized approach for automated multi-step synthesis in flow, based on systems capable of producing pharmaceutical compounds such as diphenhydramine hydrochloride, lidocaine hydrochloride, and diazepam [7].

Research Reagent Solutions and Materials

Table 3: Equipment and Reagents for Multi-Step Flow Synthesis

| Item | Function/Application |

|---|---|

| Modular Flow System | Multi-reactor platform with separate temperature zones |

| Multiple Feed Stock Solutions | Reactants for sequential transformations |

| In-line Separators (e.g., membrane-based) | Continuous phase separation |

| In-line Dryer Cartridges (e.g., MgSOâ‚„) | Continuous drying of organic streams |

| In-line Purification Modules | Continuous purification (e.g., scavenger resins) |

| Multi-port Switching Valves | Enables reagent selection and system reconfiguration |

| Control Software with Scheduling | Coordinates complex multi-step operations |

Step-by-Step Procedure

System Configuration: Design the flow setup as a sequence of modular units: feeding system → reaction module 1 → in-line separator → reaction module 2 → in-line purification → product collection. Configure temperature zones appropriate for each transformation.

Reagent Preparation: Prepare stock solutions of all starting materials and reagents in compatible solvents at predetermined concentrations (typically 0.1-1.0 M). Ensure solutions are homogeneous and particle-free to prevent clogging.

Residence Time Optimization: For each synthetic step, determine optimal residence times by varying flow rates while monitoring conversion via in-line analytics (e.g., FlowIR, HPLC).

In-line Processing Integration: Incorporate appropriate in-line processing between steps:

- For liquid-liquid extraction: Implement membrane-based separators

- For drying: Incorporate packed cartridges containing desiccants

- For purification: Use scavenger resins or catch-and-release columns

Automated Sequence Programming: Program the automated control system to coordinate:

- Sequential activation of different reagent pumps

- Switching of multi-port valves to direct flow paths

- Timing of collection vessels for fractionation

- Response to in-line analytical triggers

Process Monitoring and Control: Utilize in-line PAT to monitor key intermediates and endpoints throughout the multi-step sequence. Implement feedback control loops where possible to automatically adjust parameters based on analytical data.

Continuous Operation and Collection: Initiate the automated sequence and collect product fractions continuously. For unstable intermediates, minimize hold times between steps through careful scheduling.

Emerging Trends and Future Directions

The field of flow chemistry continues to evolve rapidly, with several emerging trends shaping its future development and application in automated synthesis research:

AI and Machine Learning Integration: The combination of flow chemistry with artificial intelligence represents a frontier in autonomous chemical synthesis. Machine learning algorithms can use data from initial runs to predict reaction behavior and optimize parameters without human intervention [2] [7]. Closed-loop optimization systems incorporate real-time analytical feedback to dynamically adjust reaction conditions, accelerating reaction discovery and optimization [1] [8].

Generative Design of Reactor Components: Advanced computational approaches, including evolutionary algorithms and generative AI, are being employed to design novel reactor geometries and mixing elements optimized for specific transformations [9]. This approach has yielded bespoke mixers with performance exceeding state-of-the-art commercial designs by 45%, demonstrating the potential for computational design to unlock new capabilities in flow chemistry [9].

Miniaturization and Modular Platforms: The trend toward miniaturized, modular microreactor platforms with high surface-area-to-volume ratios continues to enhance heat transfer efficiency and reaction control [2]. These modular systems facilitate rapid reconfiguration for different chemical transformations, increasing flexibility and reducing development time.

Advanced Additive Manufacturing: 3D printing technologies enable the production of complex reactor geometries with customized features such as integrated tempering channels for improved thermal management [9]. As materials compatible with chemical synthesis continue to develop, additive manufacturing is expected to play an increasingly important role in flow reactor fabrication.

Digital Integration and Automation: The digitization of chemical synthesis encompasses the entire experimental workflow, from automated synthesis planning to robotic execution and data management [7]. The development of standardized data formats and communication protocols (e.g., OPC UA) enables seamless integration of diverse laboratory equipment, facilitating the creation of fully automated synthesis platforms [1].

These emerging directions highlight the ongoing convergence of flow chemistry with digital technologies, advanced manufacturing, and computational design, positioning flow chemistry as a cornerstone of modern, automated chemical synthesis research.

Flow chemistry, characterized by performing chemical reactions in a continuously flowing stream, represents a foundational shift from traditional batch processing for automated synthesis research. Within a flow chemistry platform, the precise interplay of components like pumps, reactors, mixers, and pressure regulators enables enhanced control, improved safety, and greater reproducibility in chemical synthesis [1]. These automated systems are pivotal in accelerating drug discovery, allowing for the rapid exploration and optimization of reaction conditions and the generation of compound libraries with minimal human intervention [1] [7]. The digitization and automation of these platforms facilitate closed-loop optimization, where machine learning algorithms can direct experiments, thereby redefining the pace of chemical synthesis [10] [7]. This application note details the core components, their functions, and practical protocols for leveraging flow systems in automated synthesis research.

Core Components of a Flow System

A flow chemistry system is a modular assembly of specialized components that work in concert to deliver reagents, facilitate reactions, and manage the fluid stream. Understanding the anatomy and function of each unit is crucial for effective system design and operation.

Table 1: Core Components of a Flow Chemistry System.

| Component | Symbol | Description | Key Function |

|---|---|---|---|

| Pump | Drives fluid flow into the reactor. Types include syringe, gear, HPLC, and peristaltic pumps. [11] | Precise delivery of reagents at a defined flow rate, ensuring consistent residence time. | |

| Pipe/Tubing | Carries fluid between flow equipment. Commonly 1/8†or 1/16†OD tubing (e.g., PTFE). [11] | Conduit for transporting reagent and product streams throughout the system. | |

| Tubular Reactor | A coil of tubing where the reaction takes place. [11] | Provides a defined volume and residence time for single-phase reactions; mixing via diffusion. | |

| Inline Mixer | A device with a tortuous path (often with inserts) to create mixing. [11] | Ensures rapid and efficient mixing of reagent streams before they enter the reaction zone. | |

| Mixing Tee/Cross | A fitting used to merge multiple reagent streams. [11] | Point of initial contact and mixing for reagents; can serve as a reactor for very fast reactions. | |

| Continuous Stirred Tank Reactor (CSTR) | A single stirred tank with fluid inlets and outlets. [11] | Active mixing for multiphasic reactions (e.g., solid-liquid, liquid-liquid). | |

| Cascade CSTR | A chain of 'n' CSTRs. [11] | Provides consistent processing conditions and allows for intermediate reagent addition. | |

| Packed Bed Reactor | A tube filled with a fixed bed of particles (e.g., catalyst). [11] | Houses heterogeneous catalysts or reagents for catalytic reactions. | |

| Back Pressure Regulator (BPR) | A spring-loaded valve to maintain an elevated pressure within the reactor. [11] | Prevents boiling of solvents by maintaining system pressure above the boiling point at the reaction temperature. | |

| Valves | Includes 2-way, 3-way, and 4-way valves. [11] | Controls and diverts flow within the system, enabling stream selection and system reconfiguration. | |

| Injection Loop | A loop of pipe for sample storage or collection. [11] | Allows for introduction of precise reagent volumes or collection of product samples. |

Technical Specifications of Key Components

Selecting components with appropriate specifications is vital for system performance. The following table summarizes key parameters for a high-precision pump and backpressure regulator system.

Table 2: Technical Specifications for a High-Precision Pump and Backpressure Regulator System. [12]

| Parameter | UI-32 Intelligent Pump | BP-11 Auto Backpressure Regulator |

|---|---|---|

| Flow Rate Range | 0.001 – 9.999 mL/min (Low); 0.01 – 99.99 mL/min (Medium) | Compatible Flow Rate: 0.1 – 100 mL/min |

| Maximum Pressure | 40 MPa (Stainless Steel flow path); 20 MPa (PEEK flow path); 5 MPa (PCTFE flow path) | Pressure Range: 0.10 – 5.00 MPa |

| Flow Accuracy | <0.3% RSD (within 0.1 - 5 mL/min) | Control Accuracy: ± 0.1 MPa |

| Key Features | Dual-plunger linear drive for low pulsation; real-time pressure sensor; multiple wetted materials (SS, PEEK, PCTFE) | Real-time pressure feedback; mechanical force regulation via a membrane; automated pressure management |

| Communication | RS232C, RS485 | RS232C, RS485 |

System Workflow and Integration

The integration of individual components into a cohesive, automated platform is what enables advanced applications in synthesis and optimization. A typical automated flow chemistry platform follows a logical sequence from reagent introduction to product collection, with integrated analytics and control.

Diagram 1: Automated Flow Chemistry Workflow. This diagram illustrates the logical flow of material and data in a typical automated flow chemistry system. Reagents are delivered by precision pumps, mixed, and reacted in a controlled reactor. Inline analysis provides real-time data to the control software, which can adjust parameters for closed-loop optimization. The back-pressure regulator maintains a consistent system pressure.

Experimental Protocols

Protocol: Automated Optimization of a Reaction using Design of Experiments (DoE)

This protocol outlines the steps for using an automated flow platform to efficiently optimize reaction conditions, a common task in medicinal chemistry.

Research Reagent Solutions & Materials

Table 3: Essential Materials for Reaction Optimization.

| Item | Function / Specification |

|---|---|

| High-Precision Pump(s) | e.g., Dual-plunger pump with RS232 communication for precise reagent delivery. [12] |

| Tubular Reactor | Coil of PTFE or stainless-steel tubing; volume chosen based on desired residence time. [11] |

| Heating/Cooling Unit | Thermostatted jacket or bath for accurate temperature control of the reactor. [1] |

| Back Pressure Regulator | Automated BPR to prevent solvent boiling at elevated temperatures. [12] [11] |

| Inline Spectrometer | e.g., FlowIR or UV for real-time reaction monitoring. [7] |

| Control Software | Software capable of importing and executing DoE files (e.g., via OPC UA). [1] |

Methodology

- System Setup and Calibration: Assemble the flow system as per the workflow diagram (Diagram 1). Prime pumps with reagents and calibrate the inline analyzer. Establish communication between all hardware modules and the control software.

- DoE Experimental Design: Using dedicated software, design a set of experiments to screen critical continuous parameters such as residence time (controlled by total flow rate), reaction stoichiometry (controlled by relative flow rates of reagent pumps), reaction temperature, and system pressure. [1]

- Automated Experiment Execution: Import the DoE file into the flow system's control software. The software will automatically execute the sequence of experiments, adjusting the setpoints for each parameter and allowing sufficient time for the system to stabilize at new conditions before measurement. [1]

- Data Collection and Analysis: The control software logs all setpoint parameters and the corresponding output from the inline analyzer (e.g., conversion or yield) for each experiment. This data is then analyzed to build a model of the reaction space and identify the optimum conditions. [1] [7]

- Closed-Loop Integration (Optional): For advanced platforms, the output data can be fed into a machine learning algorithm. The algorithm then decides the next most informative set of conditions to run, creating a closed-loop optimization system that converges on the optimum rapidly and with minimal human input. [1] [7]

Protocol: Library Generation using an Automated Flow Platform

This protocol describes the synthesis of a compound library by varying starting materials under pre-optimized reaction conditions, a key application in early drug discovery.

Research Reagent Solutions & Materials

Table 4: Essential Materials for Library Generation.

| Item | Function / Specification |

|---|---|

| Automated Reagent Injector | Module for automatically switching between different reagent vials. [1] |

| Multi-Position Collection Module | Fraction collector for directing the product stream to specific vials. [1] |

| All components from Table 3 | For the core flow synthesis. |

Methodology

- Route and Condition Definition: Design the synthetic route and establish robust reaction conditions on the flow platform using a single set of starting materials, as verified in Protocol 4.1. [1]

- Reagent and Collection Preparation: Load the automated reagent injector with vials containing diverse starting materials. Program the collection module to assign a unique collection vial for each compound in the library.

- Automated Sequential Synthesis: Initiate the automated sequence. The platform will perform a series of experiments: for each compound, it will select the appropriate starting materials from the injector, run the reaction under the fixed, pre-optimized conditions (e.g., temperature, residence time), and direct the output to the designated collection vial. [1] This process repeats until all starting material combinations are exhausted.

- Scale-Up of Hits: Once "hit" compounds are identified from the library screening, the same flow methodology can be used with longer run-times to synthesize gram or even kilogram quantities without re-optimization, demonstrating a key advantage of flow chemistry. [1]

The Scientist's Toolkit: Essential Research Reagents & Materials

Beyond the core hardware, specific reagents and materials are fundamental to executing experiments on flow chemistry platforms.

Table 5: Key Research Reagent Solutions for Flow Chemistry.

| Category | Item | Function / Application Notes |

|---|---|---|

| Reagents & Solvents | Anhydrous Solvents | Essential for air- and moisture-sensitive reactions; compatibility with pump seals and tubing must be considered. |

| Heterogeneous Catalysts | Used in packed bed reactors; particle size should be controlled to avoid clogging and high backpressure. [11] | |

| Diverse Building Blocks | A range of commercially available starting materials for library generation in drug discovery campaigns. [1] | |

| System Components | PCTFE Flow Paths | For compatibility with a wide range of liquids, including aggressive solvents. [12] |

| Stainless Steel Flow Paths | For high-pressure applications (up to 40 MPa). [12] | |

| PEEK Flow Paths | Good chemical resistance and transparency for visible inspection of the stream. [12] | |

| Software & Data | OPC UA Connectivity | An industry-standard, open-source communication protocol that is essential for integrating flow platforms with machine learning applications and third-party software. [1] |

| Python Scripts / LabVIEW | Common programming environments used to control automated flow systems and implement closed-loop optimization. [1] [7] | |

| Benzylacyclouridine | Benzylacyclouridine, CAS:82857-69-0, MF:C14H16N2O4, MW:276.29 g/mol | Chemical Reagent |

| Kethoxal | Kethoxal, CAS:27762-78-3, MF:C6H12O4, MW:148.16 g/mol | Chemical Reagent |

The advancement of automated synthesis research is increasingly reliant on three pivotal technological classes: Transformer-based models for accurate chemical reaction prediction, chemical structure generators for exploring molecular space, and Chemical Assembly Systems (CAS) for the physical execution of reactions. When integrated within flow chemistry platforms, these technologies create a powerful, closed-loop environment for rapid molecular design, discovery, and production. This document outlines detailed application notes and experimental protocols for leveraging these tools, specifically framed for research scientists and professionals in drug development.

Transformers: Intelligent Prediction of Reaction Outcomes

Transformer models, adapted from natural language processing (NLP), have demonstrated superior capabilities in understanding and predicting chemical reactions by treating molecular representations as a language to be translated [13].

Technical Basis and Architecture

At its core, the Transformer architecture consists of an encoder and a decoder, both utilizing a self-attention mechanism [13]. This mechanism allows the model to dynamically weigh the importance of different atoms and bonds in an input molecular sequence, capturing complex, long-range dependencies that are crucial for understanding chemical reactivity [13]. In chemical applications, molecules and reactions are typically represented as text strings using the Simplified Molecular Input Line-Entry System (SMILES) or the pattern-based SMARTS notation [14] [13].

Key Models and Performance Benchmarks

Recent specialized Transformer models have set new benchmarks in predictive accuracy across multiple chemistry tasks. The table below summarizes the performance of leading models.

Table 1: Performance Benchmarks of Advanced Transformer Models for Chemical Tasks

| Model Name | Core Architecture | Key Tasks | Reported Performance | Training Data |

|---|---|---|---|---|

| ReactionT5 [15] | Text-to-text Transfer Transformer (T5) | Product Prediction, Retrosynthesis, Yield Prediction | • 97.5% Accuracy (Product Prediction)• 71.0% Accuracy (Retrosynthesis)• R² = 0.947 (Yield Prediction) | Open Reaction Database (ORD) |

| ProPreT5 [14] | T5-based | Product Prediction with SMARTS templates | High generalization to unseen reactions using generic templates. | Broad Reaction Set (BRS), USPTO MIT |

Application Protocol: Fine-tuning a Transformer for Yield Prediction

Objective: To adapt a pre-trained model like ReactionT5 for accurate yield prediction on a proprietary dataset of Pd-catalyzed coupling reactions.

Materials:

- Hardware: NVIDIA RTX A6000 GPU or equivalent.

- Software: Python, PyTorch or TensorFlow, Hugging Face Transformers library.

- Model: Pre-trained ReactionT5 weights [15].

- Data: In-house reaction dataset (SMILES format with measured yields).

Procedure:

- Data Preprocessing: Format reactions with special role tokens (e.g.,

REACTANT:,REAGENT:,PRODUCT:). Numerical yields should be normalized [15]. - Tokenization: Use the model's native tokenizer (e.g., a SentencePiece unigram tokenizer trained on SMILES) to convert input text into tokens [15].

- Model Configuration: Load the pre-trained ReactionT5 base model. Replace the final output layer to suit the regression task (single continuous neuron for yield).

- Fine-tuning: Train the model using the following representative hyperparameters [15]:

- Learning Rate: 0.005

- Optimizer: Adafactor

- Batch Size: 5

- Weight Decay: 0.001

- Validation: Monitor performance on a held-out validation set using the Coefficient of Determination (R²) to assess fit.

Fine-tuning Workflow for Reaction Yield Prediction

Generators: Exploring Constitutional Isomer Space

Chemical structure generators are computational tools that enumerate every possible constitutional isomer for a given molecular formula, providing a comprehensive map of chemical space for discovery and elucidation.

Technical Basis and Key Tools

Generators operate on principles of algorithmic group theory and combinatorial algorithms to systematically build molecular graphs that are canonical (unique) and isomorphism-free [16]. The leading open-source tool for this task is MAYGEN, which uses an orderly generation algorithm to build molecules from their adjacency matrices, leveraging Young subgroups for symmetry and canonical checking [16].

Table 2: Capabilities of Constitutional Isomer Generators

| Generator | License | Language | Example Benchmark (Câ‚â‚€Hâ‚₆O) | Key Principle |

|---|---|---|---|---|

| MAYGEN [16] | Open-source | Java | 452,458 isomers in ~10 seconds | Orderly Generation |

| MOLGEN [16] | Closed-source | C | 452,458 isomers in ~3 seconds | Proprietary |

| PMG [16] | Open-source | - | 452,458 isomers in ~45 seconds | Parallelized OMG Algorithm |

Application Protocol: Enumerating Isomers with MAYGEN

Objective: To generate all constitutional isomers for the molecular formula C₇Hâ‚â‚€Oâ‚‚.

Materials:

- Software: MAYGEN (Java JAR file).

- Hardware: Standard computer with Java Runtime Environment (JRE).

Procedure:

- Environment Setup: Download MAYGEN from GitHub and ensure JRE v8+ is installed.

- Input Preparation: The molecular formula is the direct input.

- Execution Command:

java -jar maygen-1.4.jar C7H10O2 - Output and Analysis: The tool will output all valid constitutional isomers in SMILES format. These structures can be used for virtual screening or as input for a reaction predictor to plan syntheses.

MAYGEN Isomer Generation Workflow

Chemical Assembly Systems (CAS): The Physical Execution Layer

Chemical Assembly Systems refer to the integrated hardware and software platforms that automate the physical synthesis of molecules, most effectively implemented in continuous flow chemistry.

The Flow Chemistry Advantage

Compared to traditional batch processing, flow chemistry offers enhanced safety, superior heat/mass transfer, better reproducibility, and easier scalability [7]. When automated, these systems can execute multi-step syntheses end-to-end with minimal human intervention, digitally storing optimized recipes for on-demand production [17] [7].

Protocol: On-Demand Reagent Synthesis in a Cartridge-Based Flow System

Objective: To synthesize the oxidant Dess-Martin Periodinane (DMP) on-demand from stable precursors in a cartridge-based flow reactor [17].

Materials:

- Flow Chemistry Platform: A modular system (e.g., Syrris Asia) with pumps, heaters, and cartridge reactors [1].

- Precursor Cartridge: Loaded with 2-iodobenzoic acid and potassium bromate.

- Reagent Solutions: Acetic anhydride, acetic acid.

Procedure:

- System Priming: Prime the flow system with the solvent (acetic acid).

- Reaction Execution: Pump the precursor solution and acetic anhydride through the heated reaction cartridge. The system performs the two-step synthesis (oxidation to IBX, then conversion to DMP) telescopically without isolation of intermediates [17].

- In-line Monitoring: Use an integrated FlowIR or NMR to monitor reaction progress [7].

- Product Collection: The output stream containing DMP in solvent is collected, ready for immediate use, eliminating stability concerns associated with storage [17].

Table 3: Research Reagent Solutions for Flow-Based Synthesis

| Item | Function/Description | Application Example |

|---|---|---|

| Modular Flow Reactor | Cartridge-based, reconfigurable units for multi-step synthesis. | Synthesis of Pd₂(dba)₃, DMP, NHS-diazirine [17]. |

| In-line Spectrometer | Real-time reaction monitoring (e.g., FTIR, UV-Vis). | Provides data for closed-loop optimization [7]. |

| Automated Liquid Handler | Precises injection of reagents into the flow stream. | Enables reagent screening and library generation [1]. |

| Digital Synthesis Blueprint | A digitally stored, executable reaction protocol. | Allows infinite, precise reproduction of synthetic protocols [17]. |

Integration for Autonomous Discovery: A Closed-Loop Protocol

The true power of these technologies is realized when they are integrated into a single, autonomous workflow for molecular discovery.

Objective: To automatically discover and optimize a novel small-molecule catalyst.

Materials: Integrated platform with ML driver, structure generator, predictive transformer, and automated flow assembly system.

Procedure:

- Target Definition: The machine learning (ML) driver defines a target based on desired properties.

- Structure Generation: MAYGEN generates a candidate set of isomers fitting a given formula.

- Reaction Prediction: ReactionT5 predicts viable synthetic routes to the candidates.

- Synthesis & Testing: The CAS (flow platform) executes the highest-confidence synthesis and tests the product's performance.

- Feedback and Iteration: Results are fed back to the ML driver, which refines the search and initiates the next cycle.

Closed-Loop Autonomous Discovery Workflow

The integration of modular reconfigurable platforms represents a paradigm shift in automated chemical synthesis, directly addressing the critical "Make" bottleneck in the Design-Make-Test-Analyse (DMTA) cycle within drug discovery [18]. Unlike static, purpose-built automation, these systems feature hardware and software architectures that can be rapidly reconfigured to perform a wide range of chemical transformations and multi-step sequences. This adaptability enables research teams to explore broader chemical space without the traditional time and resource penalties associated with re-tooling dedicated systems.

The core advantage lies in creating a universal execution layer between high-level synthesis planning and physical robotic operations. Platforms such as the Chemputer implement this through a chemical description language (χDL) that abstracts hardware-specific commands, allowing the same synthetic procedure to be executed across different modular configurations [19] [20]. This technical foundation enables the digitization and reproducible execution of diverse chemistry protocols, from simple coupling reactions to complex multi-step syntheses of chiral organocatalysts and pharmaceutical targets.

Platform Performance & Quantitative Assessment

Automated synthesis platforms demonstrate measurable performance advantages across critical metrics including synthesis time, yield, and reproducibility. The quantitative benefits are particularly evident in complex, multi-step synthetic sequences where traditional manual methods introduce significant operational variability.

Table 1: Performance Metrics of Automated Synthesis Platforms

| Platform / Application | Synthesis Type | Key Performance Metrics | Comparative Advantage |

|---|---|---|---|

| Chemputer Platform [19] | 3-step synthesis of chiral diarylprolinol catalysts | 34-38 hours continuous operation; 46-77% yield over 3 steps; multi-gram quantities (2.1-3.5 g) | Yields comparable to expert manual synthesis (e.g., 77% auto vs 83% manual for Cat-2) |

| AI-Integrated Robotic Platforms [21] | Diverse small molecule synthesis | Automated execution of 688 reactions over 8 days; synthesis of 15 compounds including ACE inhibitors | High-throughput experimentation with minimal human intervention |

| Radial Flow Synthesizer [21] | Library synthesis (e.g., rufinamide derivatives) | Automated multistep synthesis with inline NMR/IR monitoring | Stable and reproducible linear/convergent processes without manual reconfiguration |

| Iterative Cross-Coupling [20] | C-C bond formation for diverse small molecules | Access to 14 drug-like compound classes using >5000 commercial building blocks | Automated purification via catch-and-release methods |

The economic impact of this automation is profound in pharmaceutical research, where synthesis represents the most costly and lengthy part of the DMTA cycle, particularly for complex targets requiring multi-step routes [18]. Automated platforms fundamentally redefine synthesis rates while maintaining or improving reliability, enabling medicinal chemists to focus on strategic design rather than repetitive manual operations.

Detailed Experimental Protocols

Protocol 1: Automated Multi-Step Synthesis via Reaction Blueprints

This protocol describes the implementation of reaction blueprints—chemical analogs to functions in computer science—for executing generalized synthetic procedures on modular platforms, as demonstrated by the synthesis of Hayashi-Jørgensen type organocatalysts [19].

- Principle: Encode generalized reaction sequences with defined input parameters (reagents, conditions) to create reusable, shareable synthetic procedures executable across different modular configurations.

- Platform Requirements: Chemputer or compatible modular robotic system; liquid handling modules; temperature-controlled reactors; purification modules; χDL interpreter software [19].

Procedure:

- Blueprint Definition: Encode the general 3-step organocatalyst synthesis sequence (Grignard formation/addition, N-deprotection, O-silylation) in χDL, specifying:

- Relative stoichiometries of all components

- Variable parameters (e.g., Grignard formation time, specific acid for deprotection)

- Physical properties of reagents (molecular weight, density) for automated volume calculations [19]

- Platform Configuration: Assemble modules for liquid handling, reflux conditions, aqueous workup, and solvent evaporation. Minimal hardware reconfiguration is required between syntheses, primarily involving exchange of input reagent streams [19].

- Execution:

- Step 1 (Grignard Addition): Input aryl halide and magnesium metal; execute in situ Grignard formation followed by addition to N-Boc proline ester under blueprint-specified temperature and timing parameters.

- Step 2 (N-Deprotection): Add trifluoroacetic acid or hydrogen chloride (parameter-dependent) for Boc removal; automated aqueous workup and isolation.

- Step 3 (O-Silylation): Introduce silyl chloride (TMS, TBS, or TIPS) with base; purify crude product via automated chromatography [19].

- Product Handling: Isolate final silyl ether catalysts (e.g., (S)-Cat-1, (S)-Cat-2, (S)-Cat-3) after uninterrupted 34-38 hour operation with automated yield calculation based on mass measurement.

Troubleshooting:

- Incomplete Deprotection: If trifluoroacetic acid causes side products, switch blueprint parameter to hydrogen chloride with modified workup [19].

- Hardware Integration: Ensure χDL commands accurately map to specific module operations through platform-specific configuration files.

Protocol 2: Flow Chemistry with Real-Time Process Monitoring

This protocol implements continuous flow synthesis in a reconfigurable modular system with integrated analytical feedback for reaction optimization and control.

- Principle: Leverage precise residence time control, enhanced heat/mass transfer, and integration of inline analytics (NMR, IR) for real-time reaction monitoring in continuous flow systems [21] [22].

- Platform Requirements: Modular flow chemistry platform with reconfigurable reactor modules; computer-controlled pumps and valves; inline analytical instruments (IR, NMR); automated sample collection [21].

Procedure:

- System Priming: Prime all fluidic paths with appropriate solvents; calibrate inline analytical modules with standard references.

- Reactor Configuration: Connect pump modules, temperature-controlled reactor modules (tubular or chip), and separation/purification modules in sequence based on required chemical transformations.

- Process Operation:

- Set precise flow rates to control reactant stoichiometry and residence time.

- Maintain designated reactor temperature with tolerance of ±1°C.

- Monitor key reaction metrics (conversion, selectivity) via real-time infrared or NMR spectroscopy [21].

- Feedback Implementation:

- Use process analytical technology (PAT) data for automated adjustment of flow parameters (rate, temperature).

- Implement machine learning algorithms to correlate sensor data with reaction outcomes for continuous optimization [10].

- Product Isolation: Direct output stream through in-line liquid-liquid separation or capture columns; divert purified products to fraction collector.

Troubleshooting:

- Precipitation/Clogging: Implement in-line filters; adjust solvent composition to maintain solubility; incorporate pulse flow operation if necessary [20].

- Residence Time Distribution: Characterize with tracer studies; adjust reactor geometry or mixing elements to minimize axial dispersion.

Workflow Integration & System Architecture

The operational advantage of modular platforms is enabled by sophisticated workflow architectures that integrate digital planning with physical execution. This creates a seamless pipeline from molecular design to synthesized compound.

Figure 1: Integrated Workflow for Modular Automated Synthesis

The architecture creates a closed-loop learning system where experimental outcomes continuously inform and improve planning algorithms. This is crucial for addressing the "evaluation gap" in computer-assisted synthesis planning (CASP), where theoretical route proposals don't always translate to experimental success [18]. By capturing rich, standardized data from each experimental run, modular platforms enable the refinement of condition prediction models and retrosynthetic algorithms, progressively enhancing their real-world applicability.

Essential Research Reagent Solutions

The experimental flexibility of modular platforms is enabled by both physical reagent inventories and digital tools that expand accessible chemical space.

Table 2: Key Research Reagent Solutions for Automated Synthesis

| Resource Category | Specific Examples | Function & Application |

|---|---|---|

| Chemical Inventory Systems | Eli Lilly's automated inventory [20] | Real-time tracking, secure storage, and regulatory compliance management for millions of compounds and building blocks |

| Building Block Platforms | Enamine MADE (Make-on-Demand) [18] | Virtual catalogue of >1 billion synthesizable compounds delivered via pre-validated protocols within weeks |

| Specialized Reagents | MIDA/TIDA boronates [19] [20] | Enables automated iterative cross-coupling with simplified purification via unique binary elution properties on silica |

| Digital Synthesis Tools | Reaction Blueprints in χDL [19] | Encodes general procedures as executable functions with parameterized inputs for different reagents/conditions |

| Vendor Integration | Pre-weighted building block services [18] | Cherry-picked compounds from vendor stock; eliminates labor-intensive in-house weighing, dissolution, and reformatting |

The combination of physical inventory management and virtual building block access creates an exceptionally flexible foundation for diverse synthesis campaigns. This infrastructure enables researchers to rapidly access both standard and exotic building blocks while maintaining the reproducibility benefits of standardized sourcing and handling procedures.

Reconfigurable automated synthesis platforms deliver transformative advantages through their unique combination of hardware modularity, software abstraction, and data-driven learning. By implementing the protocols and architectures described herein, research organizations can significantly accelerate compound synthesis in drug discovery programs while enhancing reproducibility and experimental scope. The continued integration of AI-guided synthesis planning with modular execution platforms promises to further close the gap between digital design and physical realization, ultimately enabling more efficient exploration of chemical space for pharmaceutical and materials innovation.

Implementing Automation: From Library Synthesis to Self-Driving Labs

Automated Compound Library Generation for High-Throughput Screening

The integration of automated synthesis platforms and in-silico screening tools is revolutionizing early drug discovery. This paradigm shift enables researchers to navigate the vast potential chemical space, estimated to contain up to 10^60 drug-like molecules, with unprecedented efficiency [23]. Central to this evolution is the application of flow chemistry platforms, which provide a versatile and advantageous approach for the automated, continuous synthesis of compound libraries [7] [6]. These systems enhance safety by minimizing human contact with hazardous materials, offer better reproducibility and control over reaction parameters compared to batch processes, and enable direct scalability from milligram to kilogram scales without extensive re-optimization [7]. This application note details protocols and methodologies for generating high-quality compound libraries by leveraging these advanced technological synergies.

Computational Design and Virtual Screening

Navigating Ultra-Large Chemical Spaces

The first critical step in modern library generation is the computational design and prioritization of compounds. Make-on-demand combinatorial libraries, constructed from lists of substrates and robust chemical reactions, offer access to billions of readily available molecules [23]. Screening such vast spaces exhaustively with flexible molecular docking, which accounts for both ligand and receptor flexibility, is often prohibitively expensive.

Evolutionary algorithms, such as REvoLd (RosettaEvolutionaryLigand), have been developed to efficiently explore these combinatorial libraries without enumerating all possible molecules [23]. The algorithm operates on the principle of selective reproduction, where the fittest molecules from a population are chosen to generate new candidate compounds for the next generation.

REvoLd Protocol for Virtual Hit Identification

Objective: To identify high-affinity ligands for a specific protein target from an ultra-large make-on-demand library (e.g., Enamine REAL space).

- Step 1: Initialization. Generate a random starting population of 200 ligands from the combinatorial library. This provides initial diversity for the evolutionary process [23].

- Step 2: Fitness Evaluation. Dock each ligand in the population against the target protein using a flexible docking protocol like RosettaLigand to calculate a binding score (fitness) [23].

- Step 3: Selection. Select the top 50 scoring individuals (ligands) from the population to advance to the next generation [23].

- Step 4: Reproduction.

- Crossover: Recombine parts of well-performing ligands to create new offspring molecules.

- Mutation: Introduce variations through fragment switching or changing the core reaction, exploring both similar and diverse regions of the chemical space [23].

- Step 5: Iteration. Repeat Steps 2-4 for approximately 30 generations. Running multiple independent trials is recommended to discover diverse molecular scaffolds [23].

Table 1: Benchmarking Performance of the REvoLd Algorithm [23]

| Drug Target | Molecules Docked | Hit Rate Improvement Factor |

|---|---|---|

| Target 1 | ~49,000 - 76,000 | 869 - 1622 |

| Target 2 | ~49,000 - 76,000 | 869 - 1622 |

| Target 3 | ~49,000 - 76,000 | 869 - 1622 |

| Target 4 | ~49,000 - 76,000 | 869 - 1622 |

| Target 5 | ~49,000 - 76,000 | 869 - 1622 |

Figure 1: REvoLd Evolutionary Algorithm Workflow. The process iteratively improves ligand populations through selection and reproduction based on docking scores.

Automated Synthesis via Flow Chemistry Platforms

Flow Chemistry for Library Production

Once candidate molecules are identified computationally, they can be synthesized using automated and robotic flow chemistry platforms. These systems are uniquely suited for the production of small organic molecules and pharmaceutical compounds in end-to-end multistep processes [7]. Key advantages include:

- Enhanced Safety: Confining reactive species and intermediates within channels minimizes operator exposure [7] [6].

- Process Intensification: Excellent heat and mass transfer in narrow tubing enables faster reaction rates and access to wider process windows (e.g., high temperatures and pressures) [6].

- Reproducibility and Scalability: Precise control over reaction parameters (time, temperature, flow rate) ensures reproducibility, while scale-up is achieved through prolonged operation rather than system reconfiguration [7].

A representative automated flow platform, as described by Adamo et al., is a refrigerator-sized system comprising an upstream unit (stock containers, pumps, reactors, separators) and a downstream unit for purification and formulation, all controlled by integrated software [7].

Protocol: Multistep Synthesis of Pharmaceuticals in Flow

Objective: To demonstrate the automated synthesis of drug compounds like diphenhydramine hydrochloride on a continuous flow platform.

Step 1: System Configuration and Priming.

- Load all necessary reagent stocks and solvents into the designated source containers.

- Configure the software to control pumps, pressure regulators, and valves according to the synthesis pathway.

- Prime all fluidic paths with respective solvents to remove air and ensure smooth operation.

Step 2: Reaction Execution.

- The software-controlled system pumps reagents at specified flow rates into a continuous-flow reactor. Residence time is controlled by the reactor volume and total flow rate.

- For multistep syntheses, the output from the first reactor is directed into subsequent reactors or separation modules (e.g., liquid-liquid separators) for inline work-up [7].

- Implement real-time reaction monitoring using inline analytics like FlowIR (Flow Infrared Spectroscopy) [7].

Step 3: Downstream Processing and Collection.

- Direct the reacted stream to downstream modules for precipitation, crystallization, or other formulation steps as required [7].

- Collect the final product stream into a receiving vessel.

Table 2: Performance of an Automated Flow Platform for Pharmaceutical Synthesis [7]

| Pharmaceutical Product | Flow Synthesis Time | Reported Yield | Equivalent Batch Process Time |

|---|---|---|---|

| Diphenhydramine HCl | 15 minutes | 82% | >5 hours |

| Lidocaine HCl | 36 minutes | 90% | 60 minutes - 5 hours |

| Diazepam | 13 minutes | 94% | 24 hours |

| Fluoxetine HCl | Not Specified | 43% | Not Specified |

Integrated Screening: The Quantitative HTS (qHTS) Model

Compound Management for Concentration-Response Screening

The value of a generated compound library is realized through effective screening. Quantitative High-Throughput Screening (qHTS) represents a powerful model where the entire library is screened at multiple concentrations to generate concentration-response profiles from the primary screen, significantly reducing false positives [24]. This requires specialized compound management.

A robust system uses an inter-plate titration method, where a vertical dilution series is prepared across different plates. The first plate contains the highest concentration of compounds, and subsequent plates contain the same compounds in the same well locations but at serially lower concentrations [24]. This method offers flexibility for screening assays with different biological or reagent cost constraints.

Protocol: Preparation of an Inter-Plate Titration Series

Objective: To create a vertically-developed plate dilution series for a qHTS campaign in 384-well or 1536-well format.

Step 1: Compound Registration and Dissolution.

- Register all compounds in a database (e.g., ActivityBase) upon receipt, auto-generating unique identifiers [24].

- Dissolve solid compounds in DMSO to create a uniform top-concentration stock solution (e.g., 10 mM). For compounds received as solutions, transfer them into standardized, barcoded tubes [24].

Step 2: Compression into Master Plates.

- Using an automated liquid handler (e.g., Evolution P3 system), transfer compounds from 96-tube racks into a 384-well polypropylene plate in an interleaved quadrant pattern [24].

- Mix samples by aspirating and dispensing during transfer to ensure homogeneity.

Step 3: Serial Dilution and Replication.

- Perform serial dilutions in DMSO across a series of new destination plates to create the inter-plate titration series.

- The original master plate serves as the highest concentration plate. Subsequent plates are created by transferring and diluting an aliquot from the previous plate in the series.

- Seal plates heat-sealing and store them at recommended temperatures.

Figure 2: qHTS Compound Library Preparation Workflow. Compounds are processed and plated in a vertical dilution series for concentration-response screening.

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions and Hardware for Automated Library Generation and Screening

| Item | Function / Description | Example Use Case |

|---|---|---|

| RosettaLigand Software | A flexible protein-ligand docking protocol that accounts for full ligand and receptor flexibility [23]. | Evaluating binding affinity during virtual screening and evolutionary algorithm fitness evaluation. |

| Make-on-Demand Library | Ultra-large combinatorial libraries (e.g., Enamine REAL) of synthetically accessible compounds built from simple building blocks [23]. | Providing a defined, drug-like chemical space for virtual and eventual experimental screening. |

| Continuous Flow Reactor | A system where chemical reactions are performed in a continuously flowing stream within narrow tubing or microchannels [7] [6]. | Automated, scalable synthesis of target compounds with improved safety and control. |

| Process Analytical Technology (PAT) | Inline/real-time analytical tools (e.g., FlowIR) integrated into flow systems for reaction monitoring [7] [6]. | Ensuring reaction progress and quality control during automated synthesis in flow. |

| Automated Liquid Handler | Robotic system (e.g., Evolution P3) for accurate and parallel liquid manipulation in microtiter plates [24]. | High-throughput compound plating, replication, and serial dilution for qHTS. |

| Inter-plate Titration Series | A set of assay plates where the same compounds are present in the same locations across plates but at descending concentrations [24]. | Enabling quantitative HTS by generating full concentration-response curves in the primary screen. |

| DMSO | Dimethyl sulfoxide, a common solvent for preparing and storing compound stock solutions [24]. | Creating concentrated, stable stock solutions of library compounds for screening. |

| Antitumor agent-125 | Antitumor agent-125, MF:C27H34ClN4O9Pt-2, MW:789.1 g/mol | Chemical Reagent |

| Euphorbia factor L7a | Euphorbia factor L7a, MF:C33H40O7, MW:548.7 g/mol | Chemical Reagent |

Flow chemistry has matured into a valuable and widely exploited technology across academic and industrial laboratories, enabling the safe and on-demand generation of reactive intermediates using miniaturized flow setups. This technological approach allows chemists to realize safer and more streamlined synthesis routes for important chemical building blocks, particularly for challenging chemistries that are difficult to implement using traditional batch methods [25]. The precise control over reaction parameters, improved heat and mass transfer, and ability to handle hazardous materials safely make flow chemistry particularly suited for photochemistry, electrochemistry, and reactions involving unstable intermediates [26].

Within automated synthesis research, flow chemistry platforms provide the foundation for integrated systems that combine synthesis, analysis, and purification in continuous processes. These platforms are becoming increasingly essential in drug discovery, where they accelerate the exploration of chemical space and generation of compound libraries for biological screening [1]. The integration of flow technology with emerging approaches such as machine learning and artificial intelligence further enhances its capability to autonomously optimize reactions and develop efficient synthetic routes [27].

Flow Chemistry Platform Fundamentals

Advantages Over Batch Processing

Flow chemistry offers several distinct advantages over traditional batch methods, particularly for challenging chemical transformations:

Enhanced Safety: The small volume of reactive material present at any time in a flow reactor allows safe use of hazardous and explosive reagents such as alkyl lithium compounds, azides, and diazo species [6]. This "on-demand" generation and immediate consumption of reactive intermediates significantly reduces risks associated with their storage and handling [25].

Superior Process Control: Flow systems provide precise control over reaction time and temperature, decreasing the risk of undesired side-products and decomposition [6]. The ease of pressurizing flow systems enables the use of solvents at temperatures far exceeding their atmospheric boiling points, offering wide process windows and accelerated reaction rates [6].

Efficient Scaling: Optimized conditions identified in flow can be directly transferred to production scale by increasing operation time or implementing numbered-up reactor systems, avoiding the re-optimization typically required when scaling batch reactions [1] [6].

Process Intensification: The continuous nature of flow processing enables telescoping of multiple synthetic steps, including in-line purification and analysis, leading to more efficient and streamlined synthetic routes [1].

Automated Flow Chemistry Systems

Modern flow chemistry platforms are typically modular systems that can be configured for specific applications. These systems incorporate various components that work in concert to enable complex chemical transformations:

Table 1: Core Components of Automated Flow Chemistry Systems

| System Component | Function | Examples |

|---|---|---|

| Pumping System | Precise delivery of reagents at controlled flow rates | Syringe pumps, peristaltic pumps |

| Reactor Modules | Housing for chemical transformations with control of temperature, pressure | Tubular reactors, chip-based reactors, heated/cooled reactors |

| Activation Modules | Enabling specific activation methods | Photoreactors, electrochemical cells |

| Process Analytical Technology (PAT) | Real-time monitoring of reactions | Inline IR, UV, NMR spectroscopy |

| Automation & Control | Coordinating system operation and data logging | Software control, OPC UA communication |

Advanced flow chemistry systems incorporate specialized reactors for photochemistry and electrochemistry, which can be readily integrated into the overall flow setup [1]. The modular nature of these platforms allows researchers to combine multiple operations in a continuous process, from initial reagent mixing through to final product isolation [1].

Photochemistry in Flow Systems

Technological Foundations

Flow chemistry lends itself exceptionally well to photochemical transformations that are challenging in traditional batch reactors. In batch systems, poor light penetration and non-uniform irradiation often lead to poor selectivities and conversions, particularly at larger scales. Flow reactors address these limitations by minimizing the light path length and precisely controlling irradiation time [6]. The use of narrow channel dimensions in flow photochemical reactors ensures uniform illumination of the reaction mixture, leading to more consistent outcomes and reduced formation of by-products [28].

The development of efficient light source technology and optimized reactor designs has been crucial for advancing flow photochemistry [29]. Commercial flow photoreactors are now widely available from suppliers such as Vapourtec, with various configurations designed to maximize photon efficiency and throughput [6].

Electron Donor-Acceptor (EDA) Complex Photochemistry

EDA complexes have emerged as sustainable, cost-effective, and inherently safer alternatives to traditional transition metal-based photocatalysts in photochemical processes [28]. These complexes are formed via the association of neutral electron-rich and electron-deficient species, offering an environmentally benign route to radical generation across a broad spectrum of reactions [28].

The mechanism of EDA complex photochemistry involves formation of a ground-state aggregate that absorbs light at wavelengths different from the individual components, typically in the visible range. Upon irradiation, this leads to a single electron transfer from the donor to the acceptor, generating a pair of radical intermediates that can undergo subsequent transformations [28].

Diagram 1: Mechanism of Electron Donor-Acceptor (EDA) Complex Photochemistry

The integration of EDA chemistry with flow technology provides additional advantages, including enhanced light penetration, improved mixing efficiency, and better control over reaction parameters [28]. These benefits make flow systems particularly suitable for exploiting the full potential of EDA complex photochemistry.

Experimental Protocol: Flow Photochemical Reaction Setup

Materials and Equipment:

- Flow photoreactor: Commercially available system (e.g., Vapourtec UV150) or custom-built with transparent fluoropolymer tubing (e.g., FEP, PFA) [6]

- Light source: LED arrays with specific wavelength matching the reaction requirements (typically 365-455 nm for photoredox catalysis) [29]

- Pumping system: Precision syringe pumps or peristaltic pumps for reagent delivery

- Back-pressure regulator: To maintain system pressure and prevent gas bubble formation

- Reagents: Substrates, photocatalyst (if used), solvent, and other necessary additives

Procedure:

- Reagent Preparation: Prepare homogeneous solutions of all reagents in appropriate solvent. Filter if necessary to remove particulates that could clog flow channels.

- System Priming: Prime the flow system with solvent to remove air bubbles and ensure all lines are filled.

- Reactor Assembly: Set up the photochemical flow reactor, ensuring the transparent tubing is properly positioned relative to the light source for uniform illumination.

- Parameter Setting: Set the desired flow rate (which determines residence time), temperature, and system pressure.

- Reaction Execution: Switch from solvent to reagent streams and begin irradiation. Allow sufficient time for the system to reach steady state before collecting product.

- Product Collection: Collect the outflowing stream in an appropriate container, monitoring by TLC, GC, or HPLC for reaction completion.

- System Cleaning: After completion, flush the system thoroughly with clean solvent to prevent deposition of materials in the flow channels.

Key Optimization Parameters:

- Residence Time: Controlled by flow rate and reactor volume; typically 1-30 minutes for photochemical transformations

- Light Intensity: Adjusted by current to LED arrays or distance from light source

- Reagent Concentrations: Optimized to balance conversion and potential side reactions

- Solvent Selection: Chosen for solubility, transparency at reaction wavelength, and compatibility with flow system materials

Application Example: Photoredox Fluorodecarboxylation

Jerkovic et al. developed a flavin-catalyzed photoredox fluorodecarboxylation reaction using an integrated approach combining high-throughput screening and flow chemistry [6]. The initial screening employed a 96-well plate-based reactor to evaluate 24 photocatalysts, 13 bases, and 4 fluorinating agents. After identifying promising conditions, the process was transferred to flow using a Vapourtec UV150 photoreactor, achieving 95% conversion on a 2g scale [6].

Further optimization through a "custom" two-feed setup enabled scaling to 100g, and ultimately to kiloscale production where 1.23 kg of the desired product was obtained at a conversion of 97% and a yield of 92%, corresponding to a throughput of 6.56 kg per day [6]. This example demonstrates the powerful combination of high-throughput screening for rapid condition identification with flow chemistry for efficient scale-up.

Electrochemistry in Flow Systems

Principles and Advantages

Flow electrochemistry represents a transformative approach to conducting electrochemical synthesis, addressing fundamental limitations of traditional batch electrolysis. By pumping reagents through a reactor containing electrodes, flow electrochemistry eliminates poor mass transfer and thermal control issues associated with batch processes, enabling consistent exposure to an electric field and efficient heat dissipation [30].

The key advantages of flow electrochemistry include:

- Precise Redox Control: Substitution of chemical oxidants or reductants with clean, controllable electrons [30]

- Enhanced Safety: Handling of reactive intermediates at the moment of generation without accumulation [25]

- Improved Efficiency: High surface-area-to-volume ratio of flow cells enables better mass transfer and current efficiency [30]

- Simplified Scale-up: Moving from laboratory to production scale without re-optimization through reactor numbering-up or extended operation [30]

System Configuration and Operation

A typical flow electrochemistry setup consists of several key components:

Table 2: Flow Electrochemistry System Components

| Component | Specifications | Function |

|---|---|---|

| Electrochemical Reactor | Parallel plate design, undivided or membrane-divided | Houses electrodes and provides defined flow path |

| Electrode Materials | Carbon, platinum, nickel, boron-doped diamond (BDD) | Electron transfer interface; material affects selectivity |

| Power Supply | Galvanostat (constant current) or potentiostat (constant voltage) | Controls electrochemical driving force |

| Pumping System | Precision pumps with chemical resistance | Controls reagent delivery and residence time |

| Supporting Electrolyte | Salts such as LiClOâ‚„, Etâ‚„NBFâ‚„, etc. | Provides necessary conductivity without interfering with reaction |

Diagram 2: Flow Electrochemistry System Configuration

Experimental Protocol: Flow Electrosynthesis

Materials and Equipment:

- Flow electrochemical reactor: Commercial systems (e.g., Vapourtec Ion reactor) or custom-built flow cells

- Electrodes: Selected based on reaction requirements (carbon for general use, platinum for demanding oxidations, BDD for high overpotential reactions)

- Power supply: Galvanostat or potentiostat capable of delivering required current/voltage

- Pumping system: Chemically resistant pumps with precise flow control

- Supporting electrolyte: High-purity salts to ensure conductivity without side reactions

- Solvents: Appropriate for the reaction, typically anhydrous and deaerated if necessary

Procedure:

- System Assembly: Clean and install electrodes in the flow cell according to manufacturer instructions. Ensure proper connections to power supply.

- Electrolyte Preparation: Dissolve supporting electrolyte in solvent at typical concentrations of 0.1-0.5 M. Add substrates at appropriate concentrations.

- System Priming: Prime the flow system with electrolyte solution without applied potential to remove air bubbles.

- Parameter Setting: Set flow rate (typically 0.1-1.0 mL/min), temperature, applied current/voltage, and system pressure.

- Reaction Initiation: Turn on power supply and monitor cell voltage (in constant current mode) or current (in constant voltage mode).

- Process Monitoring: Use in-line or off-line analysis (GC, HPLC, etc.) to monitor conversion and selectivity.

- Product Collection: Collect output stream, typically including a downstream workup to remove supporting electrolyte.

- System Shutdown: Flush system with clean solvent before storage.

Optimization Approach:

- Current Density: Balance between reaction rate and selectivity; typically 1-50 mA/cm²

- Flow Rate: Adjust to optimize residence time and conversion

- Electrode Material: Screen different materials to improve selectivity and minimize fouling

- Electrolyte Composition: Optimize concentration and identity of supporting electrolyte

Application Example: Electrosynthetic Fluorination

Flow electrochemistry has enabled safe, scalable fluorination reactions with better selectivity and reduced environmental footprint compared to batch methods [30]. These transformations, often difficult or hazardous in batch due to the handling of fluorine sources or generated intermediates, benefit significantly from the controlled environment of flow electrochemical cells. The continuous flow approach allows for precise control of reaction time and immediate quenching of reactive intermediates, leading to improved safety profiles and reduced formation of by-products.

Handling Hazardous Reagents and Intermediates

Safety Advantages of Flow Approaches

Continuous flow technology provides powerful solutions for managing hazardous chemicals in synthesis, offering enhanced safety profiles compared to traditional batch methods. The small reactor volumes in flow systems (typically milliliters rather than liters) mean that only minute quantities of hazardous materials are present at any given time, significantly reducing the potential consequences of accidental releases or thermal runaway reactions [26]. This fundamental characteristic enables chemists to work with reactive intermediates that would be considered too dangerous for standard laboratory handling.

Flow reactors enhance process safety through multiple mechanisms:

- Contained Generation and Consumption: Hazardous intermediates are generated and immediately consumed within the closed system, avoiding accumulation [25]

- Temperature Control: Enhanced heat transfer through high surface-area-to-volume ratio prevents hotspot formation and thermal degradation [26]

- Pressure Management: Capability to operate under pressure extends the liquid range of low-boiling solvents and reagents [6]

- Automated Handling: Integration with automated platforms minimizes operator exposure to hazardous substances [1]

Classes of Hazardous Compounds Enabled by Flow

Several categories of challenging reagents and intermediates have been successfully tamed using flow chemistry approaches:

Table 3: Hazardous Reagents Enabled by Flow Chemistry

| Reagent Class | Specific Examples | Flow Approach | Application |

|---|---|---|---|

| Organometallics | Butyllithium, Grignard reagents | Low-temperature flow reactors with precise residence control | Nucleophilic additions, metal-halogen exchange |

| Azides | Organic azides, hydrazoic acid | Continuous generation and immediate consumption | Click chemistry, heterocycle synthesis |

| Diazo Compounds | Diazoacetates, diazomethane | On-demand generation in small volumes | Cyclopropanation, C-H functionalization |

| Gaseous Reagents | O₂, H₂, CO, O₃ | Gas-liquid flow reactors with optimized mass transfer | Hydrogenation, oxidation, carbonylation |

The safe handling of pyrophoric reagents such as organolithium compounds exemplifies the safety advantages of flow chemistry. By using flow reactors with precise temperature and residence time control, these highly reactive species can be generated and consumed continuously without the risks associated with their storage and manual transfer [31].

Experimental Protocol: Safe Handling of Hazardous Reagents in Flow

General Safety Considerations:

- Engineering Controls: Conduct all operations in properly functioning fume hoods or with appropriate local exhaust ventilation

- Personal Protective Equipment (PPE): Wear appropriate gloves, lab coat, and eye protection at minimum

- Emergency Planning: Have appropriate quenching solutions and spill control materials readily available

- Pressure Management: Install pressure relief devices and use pressure-rated components for reactions generating gases

Procedure for Organometallic Reagents in Flow:

- System Design: Use chemically resistant materials (e.g., stainless steel, PTFE) compatible with strong nucleophiles

- Temperature Control: Implement cooling systems to maintain appropriate temperature for reagent stability

- Mixing Optimization: Use efficient static mixing elements to ensure rapid and complete mixing of reagents

- Residence Time Control: Precisely control residence time to prevent decomposition of sensitive intermediates

- Quenching Integration: Include in-line quenching immediately after the transformation is complete

- Process Monitoring: Implement in-line analytics (e.g., FTIR, UV) to monitor reaction progress and detect deviations

Troubleshooting Common Issues:

- Clogging: Use appropriate filters and maintain sufficient system pressure

- Decomposition: Optimize residence time and temperature to minimize degradation

- Incomplete Mixing: Incorporate more efficient mixing elements or reduce flow rates

- Gas Formation: Use back-pressure regulators to maintain solubility of generated gases

Integrated Automated Platforms