Automated Synthesis Platforms in Organic Chemistry: A New Paradigm for Drug Discovery and Research

Automated synthesis platforms are revolutionizing organic chemistry by integrating robotics, artificial intelligence, and advanced engineering to accelerate molecular discovery.

Automated Synthesis Platforms in Organic Chemistry: A New Paradigm for Drug Discovery and Research

Abstract

Automated synthesis platforms are revolutionizing organic chemistry by integrating robotics, artificial intelligence, and advanced engineering to accelerate molecular discovery. This article provides a comprehensive overview for researchers and drug development professionals, covering the foundational principles of these systems—from AI-driven synthesis planning to robotic execution in both flow and batch configurations. It delves into practical applications across medicinal chemistry, including the synthesis of complex peptoids and pharmaceuticals, while also addressing key challenges such as system flexibility and purification. The content further explores optimization strategies through self-learning algorithms and in-line analytics, validates platform efficacy through comparative case studies, and concludes with the transformative impact these technologies are having on the speed, reproducibility, and safety of chemical research.

The Foundations of Lab Automation: From Robotic Arms to AI Planning

Automated synthesis refers to the use of specialized, computer-controlled equipment and robotic systems to perform chemical synthesis, enabling the highly efficient and reproducible production of chemical compounds, particularly complex molecules like peptides and pharmaceuticals [1] [2]. This approach represents a paradigm shift from traditional manual methods, offering increased speed, precision, and scalability for research and development in organic chemistry [1] [3]. In the context of modern organic chemistry research, automated synthesis platforms are foundational to achieving higher throughput, improving experimental reproducibility, and accelerating the discovery and optimization of new molecules for drug development and materials science [3] [4].

Core Concepts

The fundamental principle behind automated synthesis is the modularization and computer-control of common physical operations required to perform chemical reactions [5]. This typically involves robotic execution of a sequence of steps such as transferring precise amounts of starting materials to a reaction vessel, heating or cooling the vessel while mixing, purifying and isolating the desired product, and analyzing the product for quality and yield [2] [5]. These platforms can function as standalone automated systems or can be integrated into closed-loop, self-driving laboratories where machine learning algorithms analyze results and select the next set of experiments without human intervention [3].

A key conceptual framework in modern automated synthesis is the translation of an experimental goal into a hardware-agnostic sequence of operations. This is often achieved through specialized chemical programming languages, such as the Chemical Descriptive Language (XDL), which allows synthetic procedures to be described in a standardized, computer-readable format [6] [5]. This enables the same synthetic protocol to be executed across different robotic platforms, enhancing reproducibility and collaboration [5].

Key Terminology

- Automated Synthesis: A comprehensive term for techniques that use robotic equipment, run by software control, to perform chemical synthesis [2].

- High-Throughput Experimentation (HTE): A technique that leverages a combination of automation, parallelization of experiments, advanced analytics, and data processing to streamline repetitive experimental tasks, reduce manual intervention, and significantly increase the rate of experimental execution compared to traditional experimentation [3].

- Self-Optimizing System: A closed-loop platform that integrates automated synthesis, in-line analysis, and a machine learning algorithm to autonomously optimize reaction conditions (e.g., for yield or selectivity) by using the analytical results to propose and test improved conditions [3] [5].

- Retrosynthesis Software: Computer-aided synthesis planning (CASP) tools that use data-driven approaches, often based on artificial intelligence, to propose viable synthetic routes to a target molecule [5]. Examples include ASKCOS, Synthia, and IBM RXN [5].

- Merrifield Solid-Phase Peptide Synthesis: A seminal automated synthesis technique where the growing peptide chain is covalently attached to an insoluble polymeric support, enabling simplified purification and automation of coupling and deprotection steps [1].

- Chemical Programming Language: A domain-specific language, such as XDL, designed to describe chemical synthesis procedures in a structured, unambiguous, and hardware-independent manner [5].

- Batch Synthesis: An automated approach where reactions are performed in discrete, parallel vessels (e.g., well plates or vials) without continuous flow of materials [3].

- Flow Synthesis: A method where reactants are continuously pumped through a reactor, offering advantages for heat and mass transfer and integration with in-line analysis [5].

- Iterative Homologation: An automated synthetic strategy involving the stepwise, repeated extension of a carbon chain, such as the one-carbon insertion into boronic esters, to build complex molecular structures [2].

Quantitative Data and Performance Metrics

Table 1: Performance Metrics of Automated Synthesis Platforms

| Platform / Technique | Throughput (Reactions) | Timeframe | Key Outcome / Yield | Primary Application |

|---|---|---|---|---|

| Chemspeed SWING (Batch) [3] | 192 reactions | 4 days | Exploration of stereoselective Suzuki–Miyaura couplings | Reaction condition screening |

| Mobile Robot Chemist [3] | Not Specified | 8 days | Hydrogen evolution rate of ~21.05 µmol·hâ»Â¹ | 10-dimensional parameter search for photocatalysis |

| Automated Peptide Synthesis [1] | Significantly higher than manual | Shorter timeframe | High reproducibility and consistency | Production of therapeutic peptides |

| Text-to-Action-Sequence Model [6] | N/A (Data Processing) | N/A | 60.8% perfect action sequence match from text | Translating experimental procedures to executable steps |

Table 2: Comparison of Common Automated Synthesis Reactor Types

| Reactor Type | Key Features | Advantages | Limitations / Challenges |

|---|---|---|---|

| Batch (Well Plates) [3] | Parallel reactions in multi-well plates (e.g., 96, 48, 24-well). | High throughput for screening; excellent for varying stoichiometry and chemical formulation. | Individual control of time/temperature per well is difficult; challenges with high-temperature/reflux conditions. |

| Flow Reactors [5] | Continuous flow of reagents through a reactor. | Improved heat/mass transfer; easier integration with in-line analysis. | Requires additional planning for solubility; potential for clogging. |

| Modular Batch (e.g., Chemputer) [5] | Automated operations in classic glassware (round-bottom flasks, etc.). | High flexibility; mimics traditional lab workflow. | Requires complex engineering for sample transfer between modules. |

Experimental Protocols

Protocol 1: High-Throughput Screening of Reaction Conditions in Batch

Application: Rapid optimization of catalytic reactions (e.g., Suzuki–Miyaura coupling) [3].

- Experimental Design: Define the reaction parameter space (variables: catalyst, ligand, base, solvent, temperature, concentration). Use a design of experiments (DoE) approach or machine learning algorithm to select the initial set of conditions for the first screening round.

- Reaction Setup:

- A liquid-handling robot equipped with a syringe or pipette dispense head is used to transfer specified volumes of solvents, stock solutions of reagents, and catalysts into the wells of a 96-well reaction block [3].

- The reactor block is sealed to prevent evaporation.

- Reaction Execution: The reaction block is transferred to a heater/shaker module. Reactions proceed with mixing and heating at the predefined temperature for a set duration [3].

- Analysis: After the reaction time has elapsed, an autosampler injects crude reaction mixtures from each well into an LC/MS for analysis to determine conversion and yield [3].

- Data Processing and Iteration: Analytical data is automatically processed. A machine learning algorithm (e.g., Bayesian optimization) uses the results to predict the next, more optimal set of reaction conditions to test, and the process repeats in a closed loop [3].

Protocol 2: Automated Multi-Step Synthesis Using a Modular Platform

Application: Target-oriented synthesis of a novel organic molecule without manual intervention [5].

- Synthesis Planning: Input the target molecule structure into retrosynthesis software (e.g., ASKCOS, Synthia). The software proposes one or more viable synthetic routes [5].

- Procedure Translation: The selected synthetic route is translated into a structured, hardware-agnostic sequence of actions using a chemical programming language like XDL [5].

- Platform Execution:

- A robotic arm or gripper transfers the starting reaction vessel to a liquid handling station.

- Reagents and solvents are dispensed from a centralized chemical inventory into the vessel.

- The vessel is moved to a station for stirring and heating/cooling.

- After reaction completion, the vessel is moved to a workup station, where liquid-liquid extraction or other workup procedures may be performed automatically [5].

- The crude product may be purified using an integrated flash chromatography system.

- The purified intermediate is analyzed (e.g., by LC/MS or NMR) to confirm identity and purity before proceeding to the next step [5].

- Iteration: The process is repeated for each subsequent synthetic step, with the platform handling the transfer and setup for each new reaction until the final target molecule is synthesized and isolated.

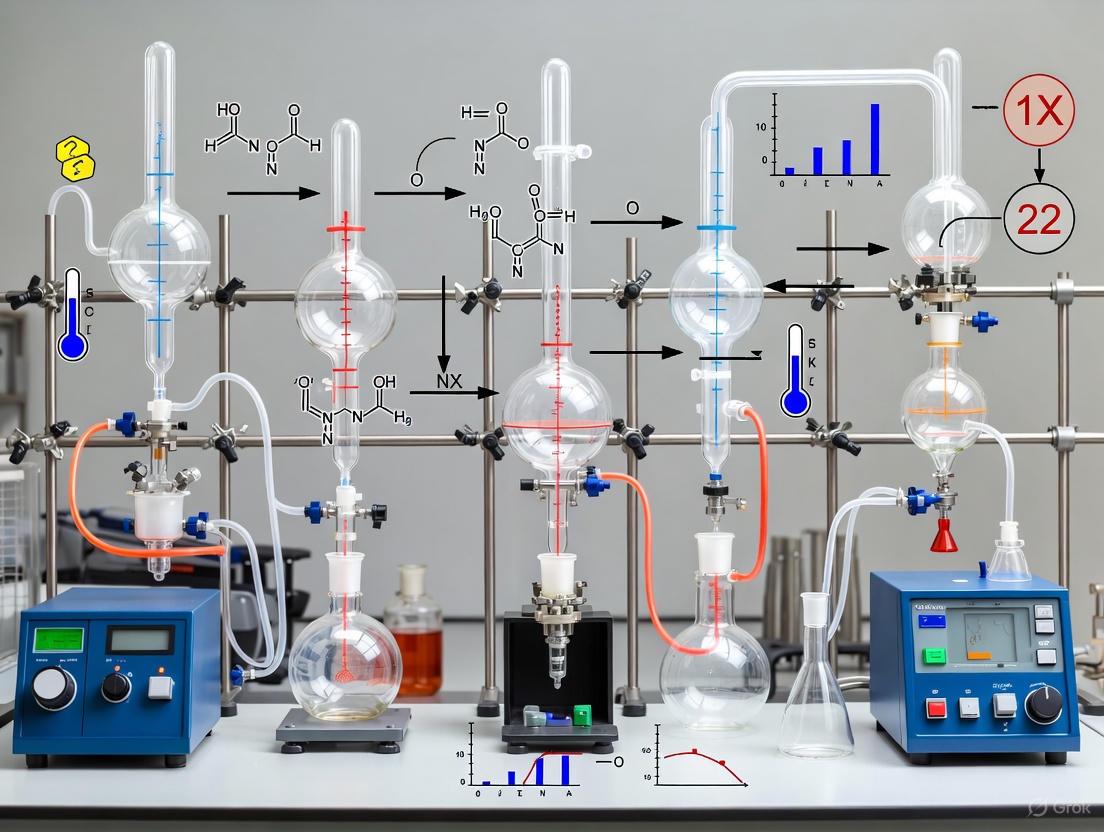

Workflow Diagram

Automated Synthesis Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents and Materials for Automated Synthesis

| Reagent / Material | Function in Automated Synthesis |

|---|---|

| Pre-filled Reagent Cartridges [7] | Disposable capsules containing pre-measured reagents for specific reaction classes (e.g., reductive amination, Suzuki coupling); enable consistent, push-button operation and simplify liquid handling. |

| MIDA-Boronates [5] | Bench-stable boronate esters used in iterative cross-coupling; their stability allows for automated "catch-and-release" purification strategies, simplifying multi-step synthesis. |

| Solid-Phase Supports (Resins) [1] | Insoluble polymeric supports to which growing molecules (e.g., peptides, oligonucleotides) are attached; facilitate automation by allowing excess reagents to be washed away without isolating the intermediate product. |

| Air-/Moisture-Sensitive Reagents | Reagents stored in specialized, sealed containers or cartridges under an inert atmosphere; integrated platforms can handle these reagents without manual glovebox use, expanding reaction scope. |

| De-gassing Agents/Enzymes [2] | Substances used in automated platforms to remove oxygen from reaction mixtures, enabling oxygen-tolerant controlled radical polymerizations (e.g., Enz-RAFT, ATRP). |

| De-protecting Agents [7] | Reagents (e.g., for Boc deprotection, silyl deprotection) available in standardized formats for automated removal of protecting groups in multi-step synthesis sequences. |

| Esomeprazole magnesium salt | Esomeprazole magnesium salt, MF:C17H19MgN3O3S, MW:369.7 g/mol |

| NMS-P715 | NMS-P715, MF:C35H39F3N8O3, MW:676.7 g/mol |

The field of organic chemistry research has undergone a profound transformation through the integration of automation, evolving from specialized peptide synthesizers to flexible, mobile robotic chemists. This evolution represents a fundamental shift in research methodology—from automated tools that execute predefined protocols to intelligent systems capable of exploratory synthesis and decision-making. The journey began with solid-phase peptide synthesis (SPPS) in the 1960s, which introduced the paradigm of insoluble polymeric supports to simplify purification and enable stepwise chain elongation [8]. For decades, automation in chemistry was characterized by highly specialized, rigid systems optimized for specific tasks like peptide synthesis or high-throughput screening [9].

The contemporary era is defined by the emergence of the "robochemist"—integrated systems where robotics and artificial intelligence (AI) converge to create platforms that not only execute experiments but also analyze results and plan subsequent steps [9] [10]. These systems mark a critical transition from automation to autonomy, with mobile robots now capable of sharing existing laboratory equipment with human researchers without monopolizing it or requiring extensive redesign [11]. This article traces this technological evolution through its key developmental stages, provides detailed experimental protocols, and explores the implications of these advancements for the future of organic chemistry research and drug development.

Historical Development and Key Technological Transitions

The Solid-Phase Revolution and Early Automation

The foundation of modern automated synthesis was laid in 1963 when Bruce Merrifield developed solid-phase peptide synthesis on crosslinked polystyrene beads, a breakthrough that would earn him the Nobel Prize [12]. The core innovation was anchoring the C-terminal amino acid to an insoluble resin support, allowing reagents in large excess to drive reactions to completion before cleaving the relatively pure peptide from the support [12]. This approach naturally lent itself to automation, with the first automated solid-phase synthesizer appearing in 1968 [12].

The 1970s and 1980s witnessed crucial refinements in SPPS methodology. In 1970, Carpino and Han introduced the base-labile 9-fluorenylmethoxycarbonyl (Fmoc) protecting group as a chemically mild alternative to the acid-labile t-butyloxycarbonyl (Boc) group [12] [8]. This established the concept of orthogonal protection schemes, where different protecting groups could be removed selectively using different mechanisms [8]. The subsequent development of specialized resins like Wang's p-alkoxybenzyl alcohol resin (1973) and Rink's TFA-labile resin (1987) further expanded synthetic capabilities [12].

Table 1: Key Historical Milestones in Automated Synthesis

| Year | Development | Significance |

|---|---|---|

| 1963 | Merrifield develops SPPS | Foundation for solid-phase synthesis and automation [12] |

| 1968 | First automated peptide synthesizer | Enabled automated stepwise peptide assembly [12] |

| 1970 | Introduction of Fmoc protecting group | Provided milder, orthogonal protection scheme [12] [8] |

| 1978 | Fmoc/tBu strategy with Wang resin | Established modern Fmoc chemistry protocol [12] |

| 1987 | Commercial multiple peptide synthesizer | Made automated synthesis widely accessible [12] |

| 2000 | Introduction of stapled peptides | Demonstrated application for potential drug leads [12] |

| 2024 | Autonomous mobile robotic chemists | Integrated mobility, AI decision-making, and multiple analytical techniques [11] |

The adoption of these technologies shifted over time. In 1991, core facilities were equally divided between Boc and Fmoc chemistry, but by 1994, 98% of participating laboratories in ABRF studies used Fmoc chemistry, citing its milder conditions and reduced side reactions [8]. Instrumentation evolved in parallel, with companies like CEM Corporation introducing microwave-assisted peptide synthesizers that dramatically reduced cycle times from hours to minutes [13].

High-Throughput Experimentation and the Station-Based Paradigm

Building on the automation principles established by peptide synthesis, the 1990s saw the pharmaceutical industry embrace High-Throughput Experimentation (HTE), integrating robotics, miniaturization, and parallelization into automated platforms [9]. HTE fundamentally changed the exploration of chemical space by enabling the evaluation of miniaturized reactions in parallel, in contrast to the traditional "one variable at a time" approach [14].

This era was characterized by station-based automation—dedicated systems for specific tasks like liquid handling, reaction execution, or analysis. These systems delivered transformative gains in throughput and reproducibility but were typically highly specialized and rigid [9]. They relieved chemists of repetitive manual work but remained limited to narrow functions and demanded constant supervision by trained specialists [9]. Despite these limitations, HTE established crucial infrastructure and methodologies for parallel experimentation that would pave the way for more autonomous systems.

The Rise of Mobile Robotic Chemists

The most significant paradigm shift in recent years has been the development of mobile robotic chemists that physically navigate standard laboratory environments. Unlike traditional stationary automation, these systems use mobile manipulators to transfer samples between specialized but physically separated stations for synthesis, analysis, and processing [11] [9].

This architectural innovation creates inherently modular and scalable workflows. In a landmark 2024 demonstration, mobile robots were integrated into an autonomous laboratory by operating a Chemspeed ISynth synthesis platform, a liquid chromatography–mass spectrometer, and a benchtop NMR spectrometer [11]. The critical advancement was that these robots could share existing laboratory equipment with human researchers without requiring extensive redesign [11]. This approach mimics human experimentation protocols more closely than previous automated systems, drawing on multiple characterization techniques (NMR and UPLC-MS) to make informed decisions about subsequent synthetic steps [11].

Table 2: Comparison of Automated Synthesis Platforms

| Platform Type | Key Features | Advantages | Limitations |

|---|---|---|---|

| Early Peptide Synthesizers | Solid-phase support; Stepwise amino acid addition; Repetitive deprotection/coupling cycles [8] | Simplified purification; Enabled automation of peptide assembly; Driven to completion with excess reagents [8] | Limited to peptide synthesis; Rigid programming; Minimal analytical integration |

| High-Throughput Screening Platforms | Miniaturization; Parallel reaction arrays; Automated liquid handling [14] | Rapid exploration of chemical space; Good for optimization; Material efficient [14] | Specialized equipment; Limited reaction scope; Often single analysis technique |

| Mobile Robotic Chemists | Free-roaming robots; Modular instrumentation; AI decision-making; Multiple analytical techniques [11] [9] | Flexible and adaptable; Uses existing lab equipment; Mimics human decision-making; Suitable for exploratory synthesis [11] | Higher complexity; Integration challenges; Currently slower than dedicated high-throughput systems |

Concurrent with these hardware advances, artificial intelligence has become increasingly embedded in autonomous systems. AI-driven platforms like "Synbot" integrate retrosynthesis planning, experimental design, and optimization modules with robotic execution systems [10]. These systems can autonomously plan synthetic routes, execute them in batch reactors, analyze outcomes, and iteratively refine their approaches based on experimental feedback [10]. The integration of large language models for extracting synthesis methods from literature further enhances their autonomous capabilities [15].

Experimental Protocols

Protocol 1: Traditional Solid-Phase Peptide Synthesis (SPPS)

Principle and Planning

SPPS involves the stepwise addition of protected amino acids to a growing peptide chain covalently attached to an insoluble resin support [8]. The C-terminal functionality (acid or amide) determines resin selection—Wang or 2-chlorotrityl resin for acids; Rink amide or Sieber amide resin for amides [16]. The protection scheme must be selected based on peptide sequence: Boc/Bzl protection for long or difficult sequences prone to aggregation; Fmoc/tBu for acid-sensitive peptides or those requiring side-chain modifications [16].

Materials and Reagents

- Resin: Appropriate solid support (e.g., Wang resin for acids; Rink amide resin for amides)

- Amino Acid Derivatives: Fmoc- or Boc-protected amino acids with appropriate side-chain protection

- Coupling Reagents: HBTU/HATU with DIEA, or DIC with HOBt/Oxyma

- Deprotection Reagents: 20-50% piperidine in DMF for Fmoc; 50% TFA in DCM for Boc

- Solvents: DMF, DCM, NMP (high purity)

- Cleavage Cocktail: TFA with appropriate scavengers (e.g., water, triisopropylsilane, ethanedithiol)

Stepwise Procedure

- Resin Swelling: Suspend the resin (0.1-0.5 mmol) in DCM or DMF (5-10 mL/g resin) for 15-30 minutes.

- Fmoc Removal (if using Fmoc chemistry): Treat resin with 20% piperidine in DMF (2 × 5-10 mL/g resin, 3-10 minutes each). Wash thoroughly with DMF (5-6 ×).

- Coupling Reaction: Add 3-5 equivalents of Fmoc-amino acid dissolved in DMF, followed by 3-5 equivalents of coupling reagent (e.g., HBTU/HATU) and 6-10 equivalents of base (e.g., DIEA). Mix for 30-90 minutes.

- Washing: After coupling, wash resin sequentially with DMF (3×), DCM (2×), and DMF (3×).

- Repetition: Repeat steps 2-4 for each additional amino acid.

- Final Deprotection: After assembling sequence, perform final Fmoc removal.

- Cleavage: Treat resin with cleavage cocktail (TFA with appropriate scavengers, 10 mL/g resin) for 2-4 hours.

- Precipitation and Isolation: Filter to remove resin, concentrate filtrate, precipitate peptide in cold diethyl ether, collect by centrifugation, and purify by preparative HPLC [8] [16].

Protocol 2: Autonomous Synthesis Using Mobile Robotic Chemists

System Configuration

This protocol describes the modular workflow for autonomous exploratory synthesis using mobile robots [11].

Equipment and Software

- Synthesis Module: Chemspeed ISynth or equivalent automated synthesizer

- Analytical Modules: UPLC-MS and benchtop NMR spectrometer

- Mobile Robots: Free-roaming robotic agents with sample manipulation capabilities

- Control Software: Central scheduling and decision-making software

- Database: Centralized data repository for experimental results

Stepwise Procedure

Experiment Initiation:

- Human researchers select target chemistry and building blocks.

- Synthesis platform prepares reaction mixtures in parallel.

- ISynth synthesizer takes aliquots of each reaction mixture and reformats them separately for MS and NMR analysis.

Sample Transportation and Analysis:

- Mobile robots transport samples to appropriate analytical instruments.

- UPLC-MS analysis performed autonomously.

- Benchtop NMR analysis performed autonomously.

- Data saved in central database with experiment identifier.

Decision-Making Cycle:

- Heuristic decision-maker processes orthogonal NMR and UPLC-MS data.

- Binary pass/fail grading applied to each analysis based on experiment-specific criteria.

- Combined results determine which reactions proceed to next stage.

- Successful reactions advanced for further elaboration or scale-up.

Iterative Optimization:

- System automatically checks reproducibility of screening hits.

- Subsequent synthesis operations determined algorithmically.

- Process continues through multiple synthesis-analysis-decision cycles without human intervention [11].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Research Reagent Solutions for Automated Synthesis

| Reagent/Material | Function | Application Notes |

|---|---|---|

| Fmoc-Amino Acids | Building blocks for peptide synthesis | Use with side-chain protecting groups stable to base deprotection but labile to TFA [8] [16] |

| Rink Amide Resin | Solid support for C-terminal amide peptides | Cleavage with 50% TFA with scavengers; standard substitution 0.5-1.2 mmol/g [16] |

| HBTU/HATU | Coupling reagents | Activates carboxyl group for amide bond formation; use with DIEA base [8] |

| Wang Resin | Solid support for C-terminal acid peptides | p-alkoxybenzyl alcohol linker; cleavage with 50% TFA [12] [16] |

| 2-Chlorotrityl Chloride Resin | Solid support for protected peptide fragments | Highly acid-sensitive; cleavage with 1% TFA for side-chain protected peptides [16] |

| TFA Cleavage Cocktail | Peptide-resin cleavage and side-chain deprotection | Typically TFA:water:triisopropylsilane (95:2.5:2.5); adjust scavengers for specific residues [8] |

| Buparlisib Hydrochloride | Buparlisib Hydrochloride, CAS:1312445-63-8, MF:C18H22ClF3N6O2, MW:446.9 g/mol | Chemical Reagent |

| MK2-IN-1 | MK2-IN-1, CAS:1314118-92-7, MF:C27H25ClN4O2, MW:472.97 | Chemical Reagent |

Workflow and System Architecture Diagrams

SPPS Cyclic Coupling Workflow

Autonomous Mobile Robotic Chemist Workflow

Modular Laboratory Architecture

The evolution from dedicated peptide synthesizers to mobile robotic chemists represents a fundamental transformation in how chemical research is conducted. What began as specialized automation for a specific class of molecules has matured into general-purpose robotic systems capable of autonomous exploratory synthesis across diverse chemical domains [11] [9]. This transition has been enabled by converging technologies: mobile robotics that provide physical interconnection between standard laboratory equipment, advanced AI that enables intelligent decision-making, and modular architectures that allow flexible reconfiguration for different chemical challenges [11] [10].

These autonomous systems are particularly valuable for exploratory synthesis where outcomes are not easily reduced to a single optimization metric, such as in supramolecular chemistry or reaction discovery [11]. Unlike traditional automation focused on optimizing known reactions, modern robotic chemists can navigate complex, multi-dimensional chemical spaces and identify promising synthetic targets based on multiple analytical criteria [11]. The future direction points toward increasingly symbiotic partnerships between human intuition and robotic precision, where AI-driven systems handle repetitive tasks and data-intensive analysis while human researchers focus on high-level strategy and creative problem-solving [9].

As these technologies mature and become more accessible, they promise to accelerate discovery across pharmaceutical development, materials science, and sustainable manufacturing. The integration of large language models for literature-based planning [15], along with more sophisticated decision algorithms that can reason across diverse data types, will further enhance the capabilities of autonomous chemical research systems. The history of automated synthesis platforms demonstrates that each technological advance has expanded the scope of addressable chemical problems, with mobile robotic chemists representing the current frontier in this ongoing evolution.

In modern organic chemistry research, particularly within automated synthesis platforms for drug development, the physical execution of designed experiments rests on three core hardware components: reaction modules, robotic grippers, and chemical inventories. These systems transform digital synthesis plans into physical reality, enabling high-throughput, reproducible, and data-rich experimentation. Their integration is crucial for advancing the Design-Make-Test-Analyze (DMTA) cycle, with automation specifically targeting the "Make" phase, often the primary bottleneck in chemical discovery [17]. This application note details the specifications, operational protocols, and integration methodologies for these components, providing a framework for their implementation in research-scale automated platforms.

Reaction Modules: Automated Synthesis Execution

Reaction modules are automated systems that perform chemical reactions by replacing manual operations like reagent addition, mixing, and heating with programmable hardware. They are primarily categorized into batch and flow systems, each with distinct advantages.

Table 1: Comparison of Automated Reaction Module Types

| Feature | Automated Batch Reactors | Automated Flow Reactors |

|---|---|---|

| Reaction Vessel | Vials (e.g., microwave), round-bottom flasks [5] [18] | Tubing or fixed-bed reactors [5] |

| Typical Scale | ~1-1000 mL total volume [18] | Continuous process, scalable [5] |

| Key Strengths | Versatility, mimics traditional lab setup [5] | Enhanced heat/mass transfer, precise parameter control [18] [4] |

| Common Hardware | Chemspeed platforms [18], "Chemputer" [5] | SRI's SynFini [5], iChemFoundry [4] |

| Automation Consideration | Requires robotic transfer between steps [5] | Requires planning for solubility, pressure [5] |

Experimental Protocol: Multi-Step Synthesis in an Automated Batch Platform

Objective: Execute a two-step synthesis with an intermediate workup and analysis using a vial-based automated batch system.

Materials:

- Automated platform (e.g., Chemspeed AUTOPLANT [18])

- Reaction vials (e.g., 100 mL total volume)

- Stock solutions of starting materials, reagents, and solvents

- Purification cartridges (e.g., for liquid-liquid extraction or drying)

- Online or autosampler-coupled LC/MS [5]

Procedure:

- Platform Initialization: Verify that all necessary solvents and reagents are available in the platform's chemical inventory. Execute a system cleaning cycle and initialize all hardware units, including the liquid handler, heater/shaker block, and analytical autosampler.

- Reaction Vessel Preparation: The robotic gripper places an empty, tared reaction vial onto the balance. The liquid handler dispenses the prescribed solvent and stock solutions of starting materials gravimetrically, confirming accurate dispensing [18].

- Reaction Execution: The gripper transfers the sealed vial to a heater/shaker block. The reaction proceeds under programmed conditions (e.g., 80°C, 600 rpm, 2 hours). The system monitors and logs parameters like temperature and pressure.

- Intermediate Analysis & Workup: After the reaction time elapses, the gripper moves the vial to a cooling station. An autosampler withdraws a crude sample for LC/MS analysis [5]. Based on a successful outcome, the liquid handler adds workup reagents (e.g., quenching solution, extraction solvent). The mixture is transferred through a purification cartridge (e.g., for drying) [18], and the gripper moves the product-containing solution to a new vial.

- Second-Step Synthesis: The liquid handler adds reagents for the second synthetic step. The procedure repeats from Step 3.

- Final Product Isolation: After the final reaction and workup, the purified product is dispensed into a labeled vial for collection or transferred to a storage location, with its new identity and location logged in the digital inventory [19].

Figure 1: Workflow for a multi-step synthesis protocol on an automated batch platform.

Robotic Grippers: The Hand of the Automated Chemist

Robotic grippers serve as the interface between the automated system and laboratory ware, enabling the transport of vessels between stations. The design of the end-effector is critical for reliability and flexibility.

Table 2: Characteristics of Robotic Gripper Types for Laboratory Automation

| Gripper Type | Mechanism | Key Advantages | Limitations | Reliability/Grasp Failure Rate |

|---|---|---|---|---|

| Parallel Jaw (Industry Standard) | Two fingers close in parallel motion | High reliability for known objects, simple control [20] | Requires bespoke fingers for different vessels; poor adaptability [21] | ~88-92% per-task success in integrated systems [20] |

| Soft Cable Loop (CLG) | A cable forms a loop that tightens around the object | High adaptability to various sizes/shapes; minimal clearance needed [21] | Specialized design; potential for cable wear over time | ≤1% grasp failures in testing [21] |

| Universal (e.g., Granular Jamming) | A soft pouch conforms to object shape then stiffens | Can grasp highly irregular objects [21] | Can be bulky; more complex control | Not specified in results |

Experimental Protocol: Reliable Vial Grasping with a Cable Loop Gripper (CLG)

Objective: Securely grasp cylindrical and prismatic laboratory vials of different sizes from a densely-packed tray with minimal clearance.

Materials:

- Robotic manipulator arm (e.g., Universal Robots UR5 [21])

- Cable Loop Gripper (CLG) end-effector [21]

- Tray containing various vials (e.g., 4-20 mL scintillation vials)

Procedure:

- Object Localization: Using a vision system (e.g., a DenseSSD object detector with >95% precision [20]), the robot identifies the type and 3D position of the target vial in the tray.

- Gripper Positioning: The robotic arm maneuvers the CLG so the cable loop is positioned around the target vial. The compliant nature of the cable allows it to be draped around the object with minimal clearance [21].

- Loop Tightening: The gripper's actuator shortens the cable, causing the loop to tighten and enclose the vial completely. The inherent compliance of the cable ensures force is distributed, accommodating slight variations in vial geometry.

- Stabilization: As the cable tightens further, the vial is pulled snugly against a rigid "finger" or support structure on the gripper. This provides stability and corrects for minor positional errors, ensuring the vial is aligned for a secure lift [21].

- Transport and Release: The robot moves the vial to its destination (e.g., a balance or heater/shaker). The actuator then releases tension on the cable, expanding the loop and releasing the vial.

Chemical Inventories: The Digital and Physical Library

A centralized and digitally-linked chemical inventory is the cornerstone of an autonomous platform, ensuring that the system knows what compounds are available and where they are located.

Table 3: Key Features of Modern Chemical Inventory Management Software

| Software Feature | Functional Role | Example Implementation |

|---|---|---|

| Structure & Sub-structure Search | Instantly find compounds by name, CAS number, or chemical structure [22] | ChemInventory [22] |

| Inventory Tracking | Real-time tracking of container location, quantity, and usage history [19] | Dotmatics Lab Inventory Management [19] |

| GHS Safety Information | Displays hazard pictograms and precautionary codes for safe handling [22] | ChemInventory [22] |

| Order Management | Streamlines the process of requesting and tracking new chemical orders [22] | ChemInventory [22] |

| Integration with ELN/RMS | Allows inventory checks and data access directly within electronic lab notebooks [19] | Dotmatics [19] |

Experimental Protocol: Automated Reagent Verification and Usage

Objective: Ensure a planned synthesis uses the correct, in-stock reagent and automatically update inventory after dispensing.

Materials:

- Chemical Inventory Software (e.g., ChemInventory [22], Dotmatics [19])

- Integrated Laboratory Information System (LIMS) or Electronic Lab Notebook (ELN)

- Automated platform with barcode/RFID reader

- Smart storage locations with IoT sensors (e.g., RFID, load cells [20])

Procedure:

- Synthesis Plan Integration: The synthesis planning software (e.g., ASKCOS [5]) generates a procedure and sends a query to the chemical inventory system to verify the availability of required reagents.

- Reagent Location & Identity Check: The inventory system returns the specific storage location (e.g., "Solvent Bay A, Position 3") of the reagent container. The robotic system navigates to this location. Optionally, a barcode or RFID reader on the gripper can scan the container to confirm its identity [20].

- Dispensing and Quantity Update: The robot dispenses the required mass or volume of the reagent. Integrated load cells in the smart tray or balance confirm the amount dispensed.

- Automated Inventory Update: The chemical inventory software automatically updates the remaining quantity of the reagent using the formula:

ΔW = W_stable - W_previous[20]. If the remaining quantity falls below a pre-set threshold, the system can automatically flag the item for reordering. - Data Logging: The software logs the transaction, creating a full audit trail that links the experiment to the specific lot and quantity of chemical used, which is critical for reproducibility [19].

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Research Reagents and Software for Automated Synthesis

| Item Name | Category | Function in Automated Synthesis |

|---|---|---|

| MIDA-boronates | Specialized Reagent | Enables iterative cross-coupling reactions via automated "catch and release" purification, simplifying multi-step synthesis [5]. |

| LC/MS with Autosampler | Analytical Instrument | Provides rapid, serial analysis of reaction outcomes for success/failure determination and yield quantification [5]. |

| AiZynthFinder | Software | An AI-powered tool for retrosynthetic planning that integrates with automated platforms to design viable synthetic routes [23]. |

| XDL (Chemical Description Language) | Software | A hardware-agnostic programming language used to describe chemical synthesis procedures for execution on different automated platforms [5]. |

| Smart Tracking Tray | Hardware/Software | An IoT-enabled tray (with RFID/load cells) that automatically logs chemical usage and updates inventory levels in real-time [20]. |

| Fmoc-Val-Cit-PAB-MMAE | Fmoc-Val-Cit-PAB-MMAE, MF:C73H104N10O14, MW:1345.7 g/mol | Chemical Reagent |

| (S)-Dolaphenine hydrochloride | (S)-Dolaphenine hydrochloride, MF:C11H13ClN2S, MW:240.75 g/mol | Chemical Reagent |

The seamless integration of robust reaction modules, adaptive robotic grippers, and intelligent chemical inventories forms the essential hardware foundation for modern, data-driven organic synthesis platforms. These components collectively enhance the reproducibility, throughput, and overall efficiency of research, particularly in demanding fields like drug development. As these technologies continue to evolve, they will play an increasingly pivotal role in closing the loop of fully autonomous discovery, allowing scientists to focus on higher-level design and interpretation.

The Role of AI and Machine Learning in Retrosynthesis Planning

The integration of Artificial Intelligence (AI) and Machine Learning (ML) into retrosynthesis planning represents a paradigm shift in organic chemistry and drug discovery. This transition moves the field away from intuition-based approaches and toward data-driven strategies, which are becoming central to automated synthesis platforms. Retrosynthesis planning, the process of deconstructing a target molecule into simpler, commercially available precursors, is a foundational task in synthetic chemistry. Modern AI models, particularly deep learning architectures, are now capable of learning the "rules" of chemical transformations from vast reaction databases, thereby accelerating the design of viable synthetic routes [24] [5]. This document provides detailed application notes and experimental protocols for leveraging these technologies, specifically framed within the context of automated organic synthesis research.

State-of-the-Art AI Models in Retrosynthesis

Current AI models for retrosynthesis can be broadly categorized into template-based, semi-template-based, and template-free methods. The performance of these models is typically evaluated on standard benchmark datasets like USPTO-50k, which contains approximately 50,000 reaction examples.

Table 1: Performance Comparison of State-of-the-Art Retrosynthesis Models on the USPTO-50k Dataset

| Model Name | Architecture/Type | Key Feature | Reported Top-1 Accuracy (%) |

|---|---|---|---|

| RSGPT [25] | Generative Transformer (Template-free) | Pre-trained on 10 billion synthetic data points; uses RLAIF | 63.4 |

| RetroExplainer [24] | Molecular Assembly / Multi-sense Graph Transformer | Interpretable, formulates task as molecular assembly | 53.2 (Class Known) |

| Graph2Edits [25] | Semi-template-based | End-to-end model integrating two-stage procedures | ~55 (approx., from context) |

| NAG2G [25] | Graph-based | Combines 2D molecular graphs and 3D conformations | ~55 (approx., from context) |

| SCROP [25] | Template-free Transformer | Integrates a grammar corrector for valid SMILES | ~55 (approx., from context) |

The quantitative data in Table 1 demonstrates that the RSGPT model currently achieves state-of-the-art performance [25]. Its success is attributed by its developers to pre-training on an extremely large dataset of over 10 billion algorithmically generated reaction datapoints, which allows the model to acquire extensive chemical knowledge. Furthermore, it incorporates Reinforcement Learning from AI Feedback (RLAIF), where the model is refined using AI-generated feedback on the validity of its predictions, more accurately capturing the relationships between products, reactants, and templates [25].

Application Notes & Experimental Protocols

Protocol A: Implementing a Transformer-Based Retrosynthesis Model (RSGPT)

This protocol outlines the steps for utilizing a large-scale generative transformer model like RSGPT for single-step retrosynthesis prediction.

1. Principle: The model treats retrosynthetic planning as a sequence-to-sequence translation task, where the Simplified Molecular-Input Line-Entry System (SMILES) string of the target product is "translated" into the SMILES string of the corresponding reactants. The model is pre-trained on massive datasets to learn the grammar of chemistry and is fine-tuned for the specific retrosynthesis task.

2. Research Reagent Solutions & Essential Materials:

Table 2: Essential Computational Tools and Datasets

| Item Name | Function/Description | Example Sources |

|---|---|---|

| Reaction Dataset | Provides labeled data for training and fine-tuning models. Contains product-reactant pairs. | USPTO-50k, USPTO-FULL, USPTO-MIT [25] [24] |

| Template Library | A set of transformation rules derived from known reactions, used for data generation or template-based methods. | RDChiral [25] |

| Cheminformatics Toolkit | Handles molecular representation, fingerprint calculation, and SMILES validation. | RDKit [23] |

| Synthesis Planning Software | A framework that integrates the retrosynthesis model for multi-step pathway search. | AiZynthFinder [23] [26] |

| Hardware-Agnostic Execution Language | Translates a planned synthetic route into machine-readable instructions for automated platforms. | XDL (Chemical Description Language) [5] |

3. Procedure:

- Step 1: Molecular Input. Represent the target molecule in a SMILES string format.

- Step 2: Model Inference. Feed the product SMILES into the pre-trained and fine-tuned RSGPT model.

- Step 3: Prediction Generation. The model generates a ranked list of candidate reactant sets. The top-ranked prediction is the model's most probable suggestion.

- Step 4: Validation Check. The generated reactants and the implied template can be validated for chemical reasonableness using a rule-based algorithm like RDChiral, which provides feedback for reinforcement learning [25].

- Step 5: Route Expansion. For multi-step synthesis, feed the predicted reactants (if not commercially available) back into the model recursively until all leaf nodes are purchasable starting materials.

The workflow for this protocol, from input to validated output, is illustrated below.

Protocol B: Interpretable Retrosynthesis via Molecular Assembly (RetroExplainer)

This protocol uses a molecular assembly paradigm to provide transparent and interpretable predictions, moving away from "black box" models.

1. Principle: RetroExplainer formulates retrosynthesis as a step-wise molecular assembly process, breaking down the target molecule through a series of interpretable, substructure-level actions guided by deep learning. This process provides quantitative attribution, showing the contribution of different molecular sub-structures to the final prediction [24].

2. Procedure:

- Step 1: Molecular Representation. Encode the target molecule using a Multi-sense and Multi-scale Graph Transformer (MSMS-GT). This model captures both local molecular structures and long-range atomic interactions, creating a robust molecular representation [24].

- Step 2: Retrosynthetic Action Prediction. The model predicts a sequence of "retrosynthetic actions," such as breaking specific bonds or removing functional groups. This is guided by a dynamic adaptive multi-task learning (DAMT) objective that balances different prediction tasks [24].

- Step 3: Structure-Aware Contrastive Learning. Employ contrastive learning to ensure that structurally similar molecules have similar representations in the model's latent space, improving the model's ability to generalize [24].

- Step 4: Pathway Attribution and Energy Curve. The model generates an energy decision curve that breaks down the prediction into stages, allowing for "counterfactual" analysis and providing confidence scores for specific chemical transformations (e.g., bond disconnections) [24].

The logical flow of this interpretable assembly process is as follows.

Integration with Automated Synthesis Platforms

For an AI-driven retrosynthesis plan to be realized, it must be translated into physical actions by an automated synthesis platform. This integration involves several critical steps and considerations.

1. From Digital Plan to Physical Execution: The synthetic route generated by AI models must be translated into a hardware-agnostic programming language, such as the Chemical Description Language (XDL), which describes the procedure in terms of generic steps like "Add," "Stir," and "Heat" [5]. This XDL file is then compiled into low-level instructions specific to the robotic hardware of the platform, such as liquid handlers and robotic grippers [5].

2. Error Handling and Adaptive Learning: A key challenge is the platform's ability to handle unexpected outcomes. An ideal autonomous platform should be adaptive, capable of using analytical data (e.g., from in-line LC/MS) to detect reaction failures and trigger re-optimization or re-planning routines [5]. Bayesian optimization, for instance, can be used to refine reaction conditions based on real-time feedback [5].

3. Case Study: Neuro-Symbolic Programming for Group Synthesis A recent advancement involves algorithms inspired by neurosymbolic programming, which learn reusable synthesis patterns for groups of similar molecules—a common scenario in drug discovery when optimizing lead compounds [27]. The system operates in three phases:

- Wake Phase: The platform attempts to solve retrosynthetic planning tasks, recording successful and failed routes.

- Abstraction Phase: The system analyzes the recorded data to extract useful multi-step strategies, such as "cascade chains" (sequences of consecutive transformations) and "complementary chains" (interdependent reactions).

- Dreaming Phase: The system uses the abstracted strategies to generate synthetic data ("fantasies"), on which its neural models practice and refine their planning capabilities [27]. This approach has been shown to significantly reduce inference time when planning synthesis for groups of structurally similar molecules [27].

The full integration cycle, from AI planning to physical execution and learning, is depicted below.

In organic chemistry research, the reproducibility of synthetic procedures represents a significant challenge, with surveys indicating that a majority of researchers have been unable to replicate published results [28]. This reproducibility crisis stems from factors such as inconsistent chemical nomenclature, incomplete procedural descriptions in publications, and human error in manual execution [28]. Automated synthesis platforms are emerging as a powerful solution to these challenges by standardizing experimental procedures, enhancing precision, and generating comprehensive, structured data [5] [14]. This Application Note details the key drivers behind adopting automated platforms and provides detailed protocols for their implementation to accelerate discovery while ensuring reproducibility.

Key Drivers for Adoption

Automated synthesis platforms are transforming organic chemistry research by addressing critical bottlenecks. The table below summarizes the primary drivers and their impact.

Table 1: Key Drivers for Adopting Automated Synthesis Platforms

| Driver | Impact on Research | Quantitative/Qualitative Benefit |

|---|---|---|

| Enhanced Reproducibility | Standardizes reaction execution and eliminates manual variability [5] [14]. | Automated platforms improve experiment precision and reproducibility compared to manual experimentation [14]. |

| Accelerated Discovery | Enables high-throughput experimentation (HTE) by miniaturizing and parallelizing reactions [14]. | Testing of 1536 reactions simultaneously via ultra-HTE significantly accelerates data generation [14]. |

| Structured Data Capture | Converts unstructured experimental procedures into structured, automation-friendly action sequences [6]. | 60.8% of sentences in test sets were perfectly converted to action sequences [6]. |

| Access to Unexplored Chemical Space | Facilitates the exploration of non-standard reagents and conditions, reducing selection bias [14]. | Mitigates reliance on familiar, available reagents to uncover novel catalysts and reactivity [14]. |

| System Integration & Self-Learning | Combines robotic hardware with AI-driven synthesis planning and outcome prediction [5] [4]. | Platforms can learn from generated data, transitioning from mere automation to full autonomy [5]. |

Experimental Protocols

Protocol 1: Automated Multi-Step Synthesis Using a Batch Platform

This protocol describes the automated synthesis of a target molecule using a vial-based batch system, such as the Chemputer or platforms from Chemspeed [5] [29]. The workflow involves synthesis planning, hardware setup, reaction execution, and product analysis.

Table 2: Research Reagent Solutions for Automated Synthesis

| Item | Function | Example/Note |

|---|---|---|

| Chemical Inventory | Provides a library of building blocks and reagents for diverse synthesis [5]. | Eli Lilly's inventory can store five million compounds [5]. |

| Pre-packed Reagent Cartridges | Ensures precise, ready-to-use doses for specific reaction classes [30]. | SynpleChem cartridges for reactions like amidation, Suzuki coupling, and Boc protection [30]. |

| Solvent Dispensing System | Automates the delivery of various solvents for reactions and work-up. | Must accommodate solvents with a range of surface tensions and viscosities [14]. |

| Liquid Handling Robot | Precisely transfers liquid reagents and solvents [5]. | Critical for dose accuracy and reproducibility. |

| Solid Dispensing System | Gravimetrically dispenses solid catalysts, ligands, and reagents [29]. | Chemspeed's system enables paradigm shift in catalyst screening [29]. |

| Analysis & Purification Modules | Provides inline analysis (e.g., LC/MS) and automated purification [5]. | LC/MS is most common; online NMR is available in advanced systems [5] [29]. |

Procedure:

- Synthesis Planning: Use a computer-aided synthesis planning (CASP) tool like ASKCOS or SYNTHIA to generate a plausible synthetic route for the target molecule [5]. Translate the proposed route into a hardware-agnostic code, such as an XDL (Chemical Description Language) script [5] [6].

- Platform Setup:

- Ensure the platform's chemical inventory is stocked with the required starting materials, reagents, and solvents [5].

- Load the appropriate reaction vessels (e.g., microwave vials) onto the platform deck.

- Verify that all fluidic paths are primed and that the system is purged for air-sensitive chemistry if required [5] [14].

- Reaction Execution:

- The platform executes the XDL script, which may include the following automated actions [5] [6]:

Add: Transfer a specified volume of solvent to the reaction vessel.Add: Dispense solid and liquid starting materials.Stir: Initiate mixing of the reaction mixture.HeatorCool: Bring the reaction to a specified temperature for a defined duration.Wait: A delay action for the reaction to proceed.

- After the reaction is complete, the platform performs a

Quenchaction if needed.

- The platform executes the XDL script, which may include the following automated actions [5] [6]:

- Work-up and Purification:

- The platform performs a

Extractaction, diluting the crude mixture with a solvent like ethyl acetate and washing it with an aqueous solution (e.g., NaOH) [6]. - The organic layer is separated and dried over a solid drying agent like sodium sulfate (

Dryaction) [6]. - The solution is

Filteredto remove solids andConcentrated in vacuo to isolate the crude product. - The crude material is purified by automated column chromatography (

Purifyaction) [5] [6].

- The platform performs a

- Product Analysis:

- An autosampler injects the purified product into an inline Liquid Chromatography-Mass Spectrometry (LC/MS) system for analysis [5].

- The platform records yield, purity, and analytical data (e.g., mass spectrum), associating them directly with the executed procedure.

Protocol 2: High-Throughput Reaction Screening & Optimization

This protocol uses High-Throughput Experimentation (HTE) to optimize reaction conditions or explore new reactivities by testing numerous variables in parallel [14].

Procedure:

- Experimental Design:

- Define the variables to screen (e.g., catalysts, ligands, solvents, bases, temperatures).

- Use a liquid handler to prepare a Microtiter Plate (MTP) where each well contains a different combination of these components. Designs can be generated using statistical methods or AI to maximize information gain [14].

- Platform Setup:

- Reaction Initiation:

- Use a multi-channel dispenser or a coordinated liquid handler to add a common starting material solution to all wells of the MTP simultaneously, initiating the reactions.

- Seal the plate and set the platform to the desired temperature with uniform stirring across all wells to mitigate spatial bias [14].

- High-Throughput Analysis:

- After the reaction time has elapsed, the plate is automatically sampled.

- Analyze the samples in a high-throughput manner using techniques like flow-injection mass spectrometry or automated LC/MS [14].

- Data Management and Analysis:

- Export analytical results (e.g., conversion, yield) into a data analysis software.

- Visualize the data using heat maps or parallel coordinate plots to identify optimal conditions and trends [14].

- The high-quality dataset generated can be used to train machine learning models for future prediction and optimization [14] [4].

Workflow and System Diagrams

Automated Synthesis Workflow

Autonomous Synthesis Platform Architecture

Platforms in Action: Flow Chemistry, Robotic Systems, and Real-World Applications

Within modern organic chemistry research, particularly in the development of automated synthesis platforms, the selection between continuous-flow and batch-based methodologies is a fundamental strategic decision. Batch chemistry, the traditional cornerstone of synthetic laboratories, processes reactants in discrete, self-contained vessels. In contrast, continuous-flow chemistry involves the steady pumping of reactants through a tubular reactor, where reactions occur as the stream progresses through the system without interruption [31]. This application note provides a detailed technical comparison of these two platforms, framing them within the context of automated synthesis to guide researchers and drug development professionals in selecting and implementing the optimal approach for their specific applications. The content is structured to furnish not only a theoretical comparison but also actionable protocols and tools for practical implementation.

Technical Comparison at a Glance

The following tables summarize the core characteristics, performance metrics, and suitability of batch and continuous-flow platforms.

Table 1: Fundamental Process Characteristics

| Feature | Batch Chemistry | Continuous-Flow Chemistry |

|---|---|---|

| Basic Principle | Reactions proceed in a discrete, sealed vessel [31]. | Reactions proceed as fluids are pumped through a reactor [31]. |

| Process Flow | Distinct start and end points for each batch; sequential processing [32]. | Uninterrupted, steady-state operation [32] [33]. |

| Operational Scale | Limited by vessel volume [34]. | Determined by operational runtime [34]. |

| Heat Transfer | Less efficient, risk of hot/cold spots in large vessels [31]. | Highly efficient due to high surface-area-to-volume ratio [31] [35]. |

| Mixing Efficiency | Dependent on stirrer type and speed; can be inhomogeneous [31]. | Highly efficient via molecular diffusion in narrow channels [34]. |

| Reaction Time Control | Determined by manual quenching/addition [31]. | Precisely controlled by adjusting flow rate and reactor volume [31]. |

Table 2: Quantitative Performance and Economic Metrics

| Metric | Batch Chemistry | Continuous-Flow Chemistry |

|---|---|---|

| Equipment Utilization | 60-70% [33] | 85-95% [33] |

| Typical Lead Time | 2-4 weeks [33] | 2-7 days [33] |

| Scale-Up Process | Non-linear, often requires re-optimization [31] | Linear, often by numbering-up or extended runtime [31] [34] |

| Initial Capital Cost | Lower [31] [33] | Higher [31] [33] |

| Production Cost per Unit | Higher [33] | Lower at high volumes [33] |

| Labor Cost per Unit | Higher [33] | Lower [33] |

| Material Waste | 5-15% [33] | 1-5% [33] |

Table 3: Application Suitability and Limitations

| Aspect | Batch Chemistry | Continuous-Flow Chemistry |

|---|---|---|

| Ideal Production Volume | Small to medium volumes, custom syntheses [31] [32] | High-volume, consistent demand [32] [33] |

| Flexibility & Customization | High; easy to change reactants and conditions between batches [31] [32] | Lower; optimized for a specific, standardized process [32] |

| Handling of Solids | Excellent; standard reactor setups cope well with precipitates [34] | Challenging; high risk of reactor clogging [36] |

| Safety Profile | Higher risk for exothermic or hazardous reactions due to large volume [31] | Superior safety; small reactor volume minimizes inherent risk [31] [35] |

| Best for Exploratory Synthesis | Excellent [31] | Poor |

| Best for Optimized, Repetitive Production | Poor | Excellent [31] |

Experimental Protocols

Protocol for a Standard Batch Suzuki-Miyaura Cross-Coupling

This protocol exemplifies a typical batch reaction suitable for automated parallel screening platforms.

3.1.1. Reagents and Materials

- Aryl halide (e.g., 4-bromotoluene), 1.0 equiv.

- Aryl boronic acid (e.g., phenylboronic acid), 1.5 equiv.

- Base (e.g., K₂CO₃), 2.0 equiv.

- Palladium catalyst (e.g., Pd(PPh₃)₄), 2 mol%

- Solvent: Toluene/Ethanol/Water mixture (e.g., 3:1:1 v/v/v)

- Inert atmosphere source (Nâ‚‚ or Ar)

3.1.2. Equipment

- Jacketed round-bottom flask (e.g., ReactoMate system [34])

- Magnetic stirrer hotplate or overhead stirrer

- Reflux condenser

- Heating circulator (e.g., connected to DrySyn block [34])

- Syringes or cannulae for reagent addition

- Automated liquid handling system (for HTS)

3.1.3. Procedure

- Charge Reactor: Place the aryl halide, boronic acid, base, and palladium catalyst into the round-bottom flask.

- Purge and Atmosphere: Add the solvent mixture. Purge the headspace of the flask with an inert gas (Nâ‚‚/Ar) for 5 minutes and maintain a slight positive pressure.

- Initiate Reaction: With stirring, heat the reaction mixture to the target temperature (e.g., 80°C) and maintain it using the heating circulator.

- Monitor Reaction: Track reaction progress by manual sampling or inline PAT (e.g., ReactIR). Typical reaction time is 2-16 hours.

- Quench and Work-up: Once complete (as determined by TLC or HPLC), cool the reaction mixture to room temperature. Transfer the mixture to a separatory funnel, dilute with water and ethyl acetate, and separate the organic layer.

- Purification: Wash the organic layer with brine, dry over anhydrous MgSOâ‚„, filter, and concentrate under reduced pressure. Purify the crude product by flash chromatography.

Protocol for a Continuous-Flow Photoredox Catalysis Reaction

This protocol demonstrates a photochemical reaction where flow chemistry offers distinct advantages in light penetration and control [35].

3.2.1. Reagents and Materials

- Substrate A (e.g., alkyl carboxylate), 1.0 equiv.

- Substrate B (e.g., fluorinating agent), 1.2 equiv.

- Photocatalyst (e.g., flavin derivative), 2 mol%

- Base (e.g., Cs₂CO₃), 2.0 equiv.

- Solvent: Acetonitrile (degassed)

3.2.2. Equipment

- Syringe pumps or HPLC pumps (two or more)

- Tubing (e.g., PFA, stainless steel) and fittings

- Photoreactor (e.g., Vapourtec UV150 [35] or Borealis [34])

- Back-pressure regulator (BPR)

- Inline degasser (optional)

- Inline PAT (e.g., FTIR or UV flow cell)

3.2.3. Procedure

- Prepare Feed Solutions: Prepare separate solutions of Substrate A and Photocatalyst in one vessel, and Substrate B and Base in another, using degassed acetonitrile.

- Prime Flow System: Load feed solutions into syringes or pump reservoirs. Prime the pumps and flow lines with solvent to remove air.

- Set Reaction Parameters: Activate the BPR to maintain system pressure (e.g., 50-100 psi). Set the flow rates of both feed pumps to achieve the desired residence time (e.g., 5-10 minutes) and stoichiometry in a T-mixer before the photoreactor.

- Initiate Flow and Irradiation: Start the pumps to combine reagent streams. Once the flow is stable and the reactor is filled, activate the LED light source in the photoreactor.

- Monitor and Collect Output: Use inline PAT to monitor conversion in real-time. Collect the product stream exiting the BPR into a receiving flask.

- Work-up and Purification: Concentrate the product stream under reduced pressure. Purify the residue via standard techniques (e.g., flash chromatography).

System Architecture and Workflow Visualization

Batch vs. Continuous-Flow Fundamental Operation

The diagram below illustrates the core architectural differences between batch and continuous-flow platforms.

High-Throughput Experimentation (HTE) Optimization Workflow

This diagram outlines a modern, automated workflow for reaction optimization, integrating both batch and flow principles with machine learning.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 4: Key Equipment and Reagents for Automated Synthesis Platforms

| Item | Function/Description | Application Notes |

|---|---|---|

| Jacketed Reactor Systems (e.g., ReactoMate, Datum) | Provides temperature control for batch reactions via an external circulator [34]. | Scalable from 50 mL to 50 L+. Essential for traditional batch process development. |

| DrySyn Multi Blocks | Aluminum blocks with wells for vials or flasks, enabling parallel reactions on a single hotplate/stirrer [34]. | Key tool for high-throughput batch screening in medicinal chemistry. |

| Microreactors / Tubular Reactors | The core component of a flow system where the reaction occurs; typically made of glass, PFA, or steel [36]. | High surface-to-volume ratio enables superior heat transfer and control. |

| Syringe & HPLC Pumps | Precisely deliver reagents at a constant, pulsed-free flow rate [36]. | Critical for maintaining stable residence times and reagent stoichiometry in flow. |

| Back-Pressure Regulator (BPR) | Maintains a set pressure within the flow system, allowing for the use of solvents above their boiling points [36]. | Enables access to superheated conditions, accelerating reaction rates. |

| In-line Sensors (FTIR, UV) | Process Analytical Technology (PAT) for real-time monitoring of conversion, intermediate formation, and impurities [36] [37]. | Enables closed-loop feedback control and autonomous optimization. |

| Photoreactors (Batch & Flow) | Provides uniform irradiation for photochemical reactions. Batch: Lighthouse; Flow: Borealis [34]. | Flow photoreactors overcome light penetration issues inherent to batch. |

| Automated Optimization Software | Machine learning algorithms that design experiments and analyze results to rapidly find optimal conditions [38] [37]. | Drives the "self-optimizing reactor," drastically reducing development time. |

| Alisol F | Alisol F, CAS:155521-45-2, MF:C30H48O5, MW:488.7 g/mol | Chemical Reagent |

| SID 26681509 | SID 26681509, CAS:958772-66-2, MF:C27H33N5O5S, MW:539.65 | Chemical Reagent |

The Chemputer is a modular, programmable robotic platform designed for the autonomous execution of chemical synthesis. Its operation is governed by the Chemical Description Language (XDL, χDL), a universal, high-level programming language that provides a standardized ontology for encoding chemical procedures in a hardware-independent manner [39]. This integrated system aims to address critical challenges in modern synthetic chemistry, including poor reproducibility, the labor-intensive nature of manual synthesis, and the inability to efficiently scale and explore complex chemical spaces [40] [39]. The core philosophy is one of chemputation—the concept that chemical code (XDL) should be able to run on any compatible hardware (the Chemputer) to yield the same result every time, analogous to the interoperability in traditional computing [39]. This framework is particularly vital for pharmaceutical research and development, where it can accelerate the discovery and optimization of new active molecules and their synthetic pathways [41].

XDL: The Language of Digital Chemistry

Core Concepts and Structure

XDL is an executable standard language for programming chemical synthesis, optimization, and discovery. Its primary function is to serve as a hardware-independent description of chemical operations, which can be compiled to run on various robotic platforms [42]. The language is built upon the universal abstraction that all batch chemical synthesis comprises four fundamental stages: Reaction, Workup, Isolation, and Purification [39]. This modular abstraction allows complex, multi-step procedures to be broken down into reusable, standardized blocks of operations.

The syntax of XDL is designed to be both human- and machine-readable. A typical XDL script defines a sequence of steps that dictate the synthesis procedure. The code example below illustrates a basic XDL structure for a reaction:

Example 1: Basic XDL execution pseudocode, demonstrating the process from loading the procedure to execution on a specific hardware platform [43].

Advanced Programming Constructs

To harness the full potential of programmable automated systems, XDL has been expanded with structured programming concepts familiar from computer science:

- Reaction Blueprints: These function as chemical analogs to software functions, allowing a set of synthesis operations to be defined once and applied to different reagents and conditions [44]. This enables the digital encoding of general synthetic procedures in a template-like form.

- Logical Control Flow: The language now supports variables, loops, and conditional statements (IF/ELSE), enabling complex, non-linear execution paths based on real-time data [44].

- Iteration and Parallelization: Procedures can be designed to execute iteratively or to run multiple syntheses in parallel, dramatically increasing throughput for optimization campaigns and library synthesis [44].

These features represent a paradigm shift from simply translating manual processes into code towards developing genuinely digital-native synthetic protocols that are more efficient, reproducible, and generalizable [44].

Quantitative Performance and Application Data

The utility of the Chemputer platform is demonstrated by its application to complex synthetic challenges. The table below summarizes key quantitative results from published studies.

Table 1: Performance Data from Automated Syntheses on the Chemputer Platform

| Synthesis Target | Type of Synthesis | Yield (%) | Scale (g) | Key Metric / Outcome | Citation |

|---|---|---|---|---|---|

| Diarylprolinol Silyl Ether (S)-Cat-1 | 3-step uninterrupted sequence | 58% | Multi-gram | Comparable to expert manual synthesis | [44] |

| Diarylprolinol Silyl Ether (S)-Cat-2 | 3-step uninterrupted sequence | 77% | Multi-gram (3.5 g) | 34-38 hours autonomous operation | [44] |

| Diarylprolinol Silyl Ether (S)-Cat-3 | 3-step uninterrupted sequence | 46% | Multi-gram (2.1 g) | Showcased blueprint reusability | [44] |

| Chiral Products | Organocatalyzed transformations | 42-97% | N/A | Up to >99:1 enantiomeric ratio (er) | [44] |

| Molecular Machines ([2]Rotaxanes) | Multi-step synthesis | N/A | N/A | Real-time monitoring via NMR/LC | [40] |

Table 2: Sensor and Analytical Instrumentation Integrated for Process Monitoring

| Sensor/Instrument | Measured Parameter | Application Example | Citation |

|---|---|---|---|

| RGBC Sensor | Colour / Turbidity | End-point detection in nitrile synthesis; formazine turbidity monitoring | [41] |

| Temperature Probe | Reaction Temperature | Preventing thermal runaway during exothermic oxidations | [41] |

| Liquid Sensor | Material Transfer | Detecting hardware failure; confirming fluid flow during filtration | [41] |

| NMR Spectrometer | Reaction Conversion | Real-time feedback for molecular machine synthesis | [40] [41] |

| HPLC System | Product Purity/Yield | Closed-loop optimization of Ugi and Van Leusen reactions | [41] |

| Raman Spectrometer | Reaction Progress | Monitoring reaction pathways for optimization | [41] |

Detailed Experimental Protocols

Protocol: Automated Synthesis of a Hayashi-Jørgensen Organocatalyst

This protocol details the automated three-step synthesis of a diarylprolinol silyl ether catalyst, a representative example utilizing reaction blueprints and logical control flow [44].

Principle: The synthesis follows a general sequence starting from an N-protected proline ester: 1) organometallic addition of a Grignard reagent, 2) N-deprotection, and 3) O-silylation. The procedure is encoded as a reusable blueprint where only the input reagents and specific parameters (e.g., Grignard formation time) are modified for different catalyst variants [44].

Table 3: Research Reagent Solutions for Organocatalyst Synthesis

| Reagent / Material | Function / Role | Blueprint Parameter |

|---|---|---|

| N-Boc Proline Ester | Core prolinol scaffold building block | Input Reagent |

| Aryl Halide (e.g., Ar-X) | Precursor for Grignard reagent; defines catalyst aryl group | Input Reagent |

| Magnesium Turnings | Source for Grignard reagent formation | Fixed in Blueprint |

| Trifluoroacetic Acid (TFA) | Reagent for N-Boc deprotection | Parameter (can be switched to HCl) |

| Silyl Chloride (e.g., TBDMS-Cl) | Electrophile for O-silylation | Input Reagent |

| Triethylamine (Base) | Acid scavenger during silylation | Fixed in Blueprint |

Procedure:

Reaction Blueprint: Grignard Formation and Addition

- Add the specified aryl halide and magnesium turnings to the reaction vessel in an anhydrous ethereal solvent under an inert atmosphere.

- Heat the mixture to reflux for a defined period (a key Parameter, e.g., 2 hours). The blueprint can include a dynamic step where a colour sensor monitors the onset of the Grignard reaction.

- Cool the resulting Grignard reagent solution to 0 °C.

- Add a solution of the N-Boc proline ester in an ethereal solvent slowly via the liquid handling system, maintaining the temperature.

- Stir the reaction mixture at 0 °C, allowing it to warm to room temperature gradually, and monitor for completion (e.g., via in-line LC or a fixed time).

Reaction Blueprint: N-Deprotection

- Quench the reaction mixture carefully with a saturated aqueous ammonium chloride solution.

- Extract the aqueous layer with an organic solvent (e.g., ethyl acetate). The blueprint defines the liquid-liquid extraction steps.

- Add the specified acid (TFA or HCl, a critical Parameter) to the combined organic extracts to remove the N-Boc protecting group.

- Stir until deprotection is complete, as determined by in-line analysis or a predefined time.

Reaction Blueprint: O-Silylation

- Add the specified silyl chloride (e.g., TBDMS-Cl) and a stoichiometric base (e.g., triethylamine) to the reaction mixture.

- Stir the reaction at room temperature until the silylation is complete.

- Workup and Isolate the product via a standardized workup and purification blueprint, which may include washing, drying, and solvent evaporation steps.

Notes:

- The entire sequence runs autonomously over 34-38 hours [44].

- The power of blueprints is shown by the ability to troubleshoot: if deprotection with TFA leads to side-products (as encountered for (S)-Cat-2 and (S)-Cat-3), the acid parameter can be changed to HCl in the XDL code without altering the core procedure [44].

- All stoichiometries are encoded using relative values, and the Chemputer's software calculates absolute volumes and masses based on the defined properties (e.g., density, molecular weight) of the input reagents [44].

Protocol: Closed-Loop Self-Optimization of a Reaction

This protocol describes how the Chemputer platform is used for autonomous reaction optimization, leveraging dynamic XDL steps and in-line analytics [41].

Principle: A baseline XDL procedure for a target reaction is executed. An in-line analytical instrument (e.g., HPLC, NMR) quantifies the reaction outcome (e.g., yield). An optimization algorithm (e.g., from the Summit or Olympus frameworks) processes this result and suggests a new set of reaction conditions (e.g., temperature, stoichiometry) for the next experiment. The system dynamically updates the XDL procedure and repeats the cycle [41].

Procedure:

Initialization:

- The user provides the baseline XDL procedure, a hardware graph, and a configuration file specifying the variable parameters to optimize and the desired objective (e.g., maximize yield).

- The ChemputationOptimizer software is initialized with the chosen optimization algorithm [41].

Optimization Loop:

- The system compiles and executes the XDL procedure on the Chemputer.

- Upon reaction completion, an automated sampling step is triggered.

- The sample is transferred to an in-line analytical instrument (e.g., HPLC). The

AnalyticalLabwarePython package controls the instrument and acquires the data (e.g., a chromatogram) [41]. - The data is processed in real-time (e.g., peak integration) to calculate the reaction outcome (yield).

- The outcome and corresponding parameters are stored in a database.

- The optimization algorithm analyzes all accumulated data and proposes a new set of reaction conditions for the next iteration.

- The original XDL procedure is dynamically updated with these new parameters.

Termination:

- The loop continues until a predefined terminal condition is met, such as a target yield, a maximum number of iterations (e.g., 25-50), or convergence of the algorithm [41].

Application Example: This approach has been successfully demonstrated for the Van Leusen oxazole synthesis, a four-component Ugi reaction, and manganese-catalysed epoxidations, achieving yield improvements of up to 50% over 25-50 iterations [41].

System Architecture and Workflow Visualization

The following diagrams, generated using the DOT language, illustrate the logical architecture of the Chemputer/XDL system and a core programming concept.

Diagram 1: Integrated Chemputer System Architecture. This diagram shows the flow from a high-level, hardware-independent XDL procedure to its compilation and execution on the physical Chemputer hardware, including the critical feedback loops for autonomous optimization.

Diagram 2: Reaction Blueprint Concept. This diagram illustrates how a single, general reaction blueprint can be instantiated with different input parameters to produce distinct chemical outputs, enabling the rapid synthesis of compound libraries.