Radial Synthesis Systems: Revolutionizing Automated Organic Molecule Library Production

This article explores the transformative role of radial synthesis systems in the automated construction of organic molecule libraries, a critical task for drug discovery and development.

Radial Synthesis Systems: Revolutionizing Automated Organic Molecule Library Production

Abstract

This article explores the transformative role of radial synthesis systems in the automated construction of organic molecule libraries, a critical task for drug discovery and development. Aimed at researchers, scientists, and drug development professionals, it provides a comprehensive examination spanning from the foundational principles of this technology to its practical implementation. The content covers the core architecture of radial synthesizers, their application in multi-step synthesis and on-demand production, advanced strategies for scheduling and process optimization, and a comparative analysis with other flow chemistry platforms. By synthesizing the latest research, this review serves as a guide for integrating this paradigm-shifting technology into modern chemical research and production workflows.

Radial Synthesis Demystified: Core Principles and System Architecture

Radial synthesis represents a fundamental paradigm shift in automated chemical production, moving from traditional linear assembly lines to a centralized hub-and-spoke configuration. This novel approach enables unprecedented flexibility in organic molecule synthesis, allowing for single-step, multistep, and library syntheses without requiring physical reconfiguration of the instrument between processes. By providing equal access to diverse reaction conditions through a central switching station, this technology democratizes chemical synthesis and accelerates drug discovery through rapid, remotely accessible production of complex molecules [1] [2]. The following application notes detail the principles, implementation, and practical protocols for leveraging radial synthesis systems in research and development settings.

Historical Context and Limitations of Existing Systems

Traditional automated synthesis platforms have predominantly relied on linear configurations where chemical transformations occur sequentially in an assembly-line fashion. While effective for dedicated processes, these systems present significant limitations for research and development applications. Each new target molecule typically requires extensive reconfiguration of the entire system to accommodate different reaction conditions, solvents, and purification requirements. This reconfiguration process demands time, expertise in flow chemistry, and physical manipulation of equipment, creating bottlenecks in the discovery and optimization pipeline [3].

Chemical production has traditionally been a bespoke process where equipment arrangement is specifically dedicated to one product. This approach lacks the rapid flexibility needed when market demands fluctuate suddenly, as evidenced by recurrent shortages of essential medicines across global markets. The discontinuous batch mode of operation that dominates pharmaceutical production protracts manufacturing times to several months and requires large equipment with well-known scale-up difficulties [4].

The Radial Synthesis Solution

Radial synthesis addresses these limitations through an innovative architecture where various reaction modules are radially arranged around a central switching station. Much like destinations from a central train station, variable reaction conditions—including heated reactors, photoreactors, and analytical equipment—are equally accessible for round-trip passage to perform desired reactions [2]. This configuration enables:

- Sequential, non-simultaneous reactions that can be combined to perform multistep processes

- Variable flow rates and reuse of reactors under different conditions

- Intermediate storage capabilities for convergent syntheses

- No physical reconfiguration requirements between different synthetic processes [1]

This technology represents more than incremental improvement—it constitutes a paradigm shift in how chemical synthesis is performed, particularly for research applications requiring versatility and rapid adaptation.

Technical Specifications and System Architecture

Core Components of a Radial Synthesis System

The radial synthesizer comprises four main sections that work in concert to enable flexible, automated synthesis:

Reagent Delivery System (RDS): This subsystem stores and delivers chemical reagents to the central switching station. It typically includes multiple reservoirs for starting materials, catalysts, and solvents, with precision pumping mechanisms to ensure accurate stoichiometries [4].

Central Switching Station (CSS): Acting as the hub of the system, the CSS directs reagent streams to appropriate reaction modules and routes products to subsequent steps or collection vessels. This component enables the system's signature flexibility without physical reconfiguration [4].

Radially Arranged Reactor Modules: Various specialized reactors (temperature-controlled coils, photochemical reactors, etc.) are positioned as satellites around the CSS. The system can include multiple reactor types, each optimized for specific chemical transformations [1].

Standby Module (SM): This component provides temporary storage for reaction intermediates during multistep syntheses, enabling both linear and convergent synthetic pathways [4].

Collection Vessels (C): Final products and samples for analysis are directed to appropriate collection vessels, which may include interfaces for inline purification or analytical instrumentation [4].

Pathway Configuration and Flow Dynamics

The radial architecture enables six principal pathways for solution flow, defined by their starting points and destinations:

- R-C Pathway: Reagents from RDS through a reactor to collection (for single-step syntheses)

- R-S Pathway: Reagents from RDS to standby module (for intermediate storage)

- S-C Pathway: From standby module through a reactor to collection (for subsequent steps)

- S-S Pathway: From standby through a reactor back to standby (for multi-step processing)

- R-R Pathway: Reagents from RDS through reactor and back to RDS (for recursive processing)

- C-C Pathway: From collection through reactor back to collection (for product manipulation) [4]

This pathway diversity enables the system to perform virtually any single-step, multistep, or library synthesis without physical reconfiguration.

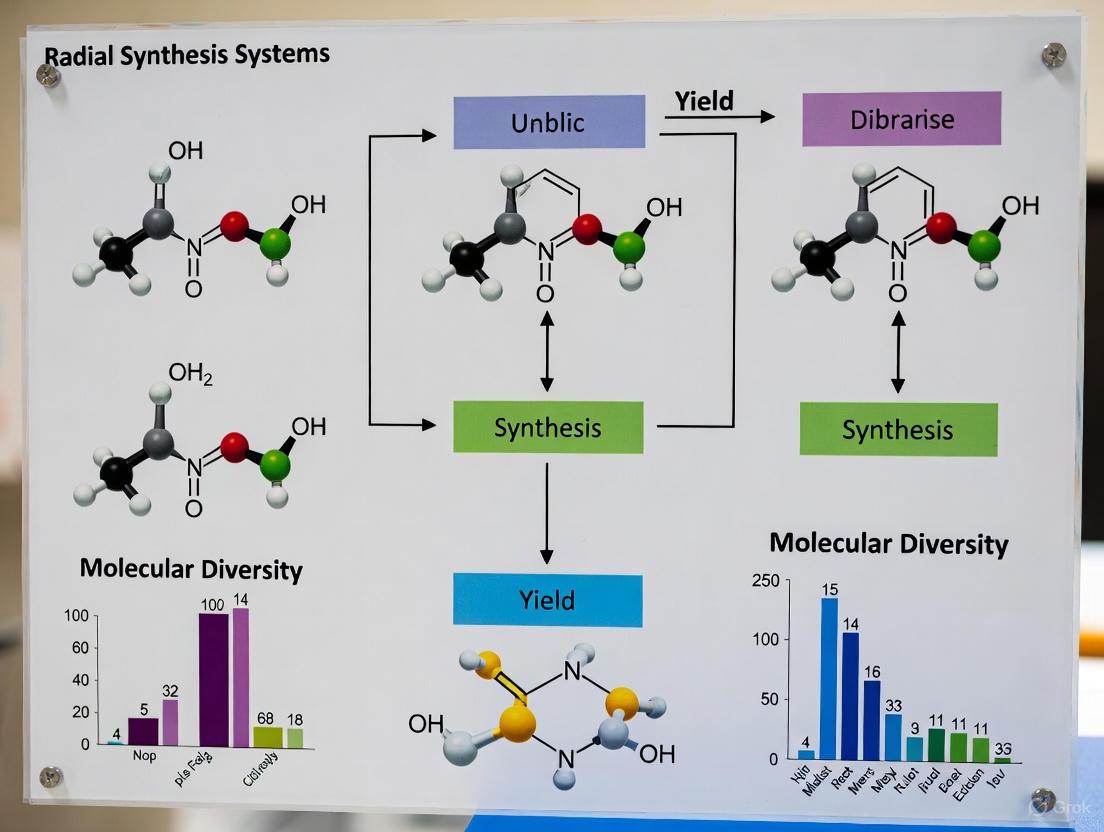

Figure 1: Radial Synthesis System Architecture. This diagram illustrates the core components and flow pathways of a radial synthesis system, highlighting the central switching station that enables flexible routing without physical reconfiguration.

Research Reagent Solutions: Essential Materials for Radial Synthesis

Table 1: Key Research Reagent Solutions for Radial Synthesis Applications

| Reagent Category | Specific Examples | Function in Radial Synthesis |

|---|---|---|

| Pharmaceutical Precursors | 4-aminophenol, acetic anhydride, 2-nitrobenzaldehyde, methyl acetoacetate, methyl 3-aminocrotonate, 2,6-dimethylaniline [4] | Essential building blocks for API synthesis; selected for compatibility with continuous flow systems |

| Catalytic Systems | Metallaphotoredox catalysts [1] [5] | Enable modern cross-coupling transformations under mild conditions in dedicated reactor modules |

| Solvent Systems | Water/acetic acid mixtures, ethanol, methanol [4] | Optimized for solubility and reaction efficiency in flow chemistry applications |

| Specialized Reagents | Ammonium acetate [4] | Facilitate specific transformations like aminophenol formation and acetylation |

Experimental Protocols and Applications

Protocol 1: Synthesis of Paracetamol via Radial Synthesis

Background and Objective

Paracetamol (acetaminophen) is a widely used analgesic and antipyretic medication that experienced supply shortages during the COVID-19 pandemic [4]. This protocol details an optimized synthesis of paracetamol from 4-aminophenol using the radial synthesis approach, demonstrating rapid access to essential medicines.

Experimental Setup and Reagents

- Radial synthesizer configured with R–C pathway

- Reactor: 10 mL PFA coil reactor at ambient temperature

- Reagent A: 4-aminophenol (4) in water/acetic acid (4:1, 2 M)

- Reagent B: Neat acetic anhydride (5)

- Stoichiometry: 1 equivalent 4-aminophenol to 3 equivalents acetic anhydride [4]

Step-by-Step Procedure

System Preparation: Load Reagent A into specified reservoir in Reagent Delivery System (RDS). Load Reagent B into separate reservoir in RDS.

Pathway Selection: Program the Central Switching Station (CSS) to implement R–C pathway (Reagent Delivery System to Collection vessel via reactor).

Reaction Execution: Simultaneously pump Reagent A (1.5 mL minâ»Â¹) and Reagent B (0.45 mL minâ»Â¹) through the system, combining at the CSS before passing through the 10 mL reactor coil.

Residence Time Control: Maintain combined flow rate of 1.95 mL minâ»Â¹ through the 10 mL reactor, achieving a residence time of approximately 5 minutes at ambient temperature.

Collection and Crystallization: Collect effluent in a vessel and stir at room temperature for 1 hour to allow product crystallization.

Purification and Analysis: Isolate crystallized paracetamol by filtration. Analyze product purity by appropriate analytical methods (HPLC, NMR) [4].

Results and Performance Metrics

- Yield: 94% (6.36 g from 15-minute runtime)

- Productivity: 25.6 g hâ»Â¹ (equivalent to 1229 doses per day)

- Purity: >95% by HPLC analysis

- Advantages: No precipitation observed during flow process; rapid crystallization upon standing [4]

Protocol 2: Multistep Synthesis of Lidocaine

Background and Objective

Lidocaine is a local anesthetic frequently experiencing supply shortages in various markets [4]. This protocol demonstrates the capability of radial synthesis for multistep transformations through a two-step synthesis of lidocaine, highlighting the system's ability to store intermediates and perform sequential reactions.

Experimental Setup and Reagents

- Radial synthesizer configured for multiple pathways

- Reactor: 10 mL PFA coil reactor (reused for different conditions)

- Step 1 Reagents: 2,6-dimethylaniline, chloroacetyl chloride, solvents

- Step 2 Reagents: Diethylamine, additional solvents [4]

Step-by-Step Procedure

First Step Configuration: Program CSS for R–S pathway (Reagent Delivery System to Standby Module).

Step 1 Execution: Pump reagents for the first transformation through the reactor under optimized conditions (specific temperature and residence time) to the Standby Module for intermediate storage.

Second Step Configuration: Reprogram CSS for S–C pathway (Standby Module to Collection via reactor).

Step 2 Execution: Combine the stored intermediate with additional reagents from the RDS (diethylamine) and pass through the reactor under appropriate conditions for the second transformation.

Product Collection: Direct the final effluent to collection vessels for isolation and purification [4].

Technical Notes

- The same 10 mL coil reactor is used for both steps but under different temperature and flow rate conditions

- Flow rates can be adjusted independently for each step to achieve optimal residence times

- The standby module enables flexible timing between synthetic steps

- This approach demonstrates true multistep capability without hardware reconfiguration [4]

Advanced Application: Library Synthesis for Drug Discovery

Background and Objective

Traditional automated library synthesis typically involves single-step procedures targeting a single structural vector. The radial synthesis approach enables more sophisticated multistep and multivectorial library generation, allowing researchers to explore synergistic structure-activity relationships (SAR) by concurrently varying multiple structural elements [5].

Implementation Strategy

Modular Design: Implement up to eight different synthetic methodologies, including established chemistries, metal-catalyzed transformations, and modern metallaphotoredox couplings [5].

Vectorial Exploration: Design libraries that systematically vary structural elements around a central core, exploring multiple vectors simultaneously.

Pathway Diversification: Utilize different R–C, R–S, and S–C pathways to create structural diversity through varied synthetic routes.

High-Throughput Execution: Leverage the fully automated nature of the system to achieve production rates of up to four compounds per hour [5].

Table 2: Performance Metrics of Radial Synthesis in Pharmaceutical Applications

| Application | Yield (%) | Productivity | Key Advantages |

|---|---|---|---|

| Paracetamol Synthesis | 94 [4] | 25.6 g hâ»Â¹ [4] | Rapid optimization, direct scalability, continuous production |

| Rufinamide Derivatives | Not specified | 18 compounds via different pathways [1] | Multiple synthetic routes without reconfiguration, rapid SAR exploration |

| Library Synthesis | Not specified | 4 compounds per hour [5] | Multivectorial SAR, combination of diverse chemistries |

| Metallaphotoredox C-N Coupling | Not specified | Performed in dedicated module [1] | Access to challenging transformations, specialized conditions on demand |

Scale-Up Integration: From Discovery to Production

A significant advantage of the radial synthesis approach is the seamless transition from discovery to production. The system enables a unified workflow:

Reaction Discovery and Optimization: The radial synthesizer enables rapid screening of reaction conditions, stoichiometries, and solvents using discrete volumes of solutions [4].

Route Scouting: Multiple synthetic pathways can be evaluated for target molecules without system reconfiguration, as demonstrated with the anticonvulsant drug rufinamide [1].

Direct Scale-Up: Conditions optimized on the radial synthesizer (temperature, pressure, concentration, stoichiometry, solvent, and residence time) are directly transferable to commercial continuous flow systems for production at gram to kilogram scale [4].

On-Demand Production: The approach enables flexible, decentralized manufacturing of pharmaceuticals, potentially alleviating drug shortages through localized production capabilities [4].

Figure 2: Integrated Workflow from Discovery to Production. This diagram illustrates the seamless transition from reaction optimization and library generation using radial synthesis to direct scale-up and on-demand production in continuous flow systems.

Radial synthesis represents more than a technical improvement in automated chemical synthesis—it constitutes a fundamental paradigm shift in how chemical production is conceptualized and implemented. By providing a versatile, reconfiguration-free platform that can perform both single-step and multistep syntheses across diverse reaction conditions, this approach significantly accelerates the discovery and development of new chemical entities.

The democratization of advanced synthesis through remotely accessible technology promises to expand participation in chemical research beyond traditionally well-resourced institutions. Furthermore, the generation of standardized, reproducible chemical data at scale provides the foundation for future applications of artificial intelligence and machine learning in molecular design and reaction prediction [2].

As the field of chemical synthesis continues to evolve, radial synthesis systems stand to play an increasingly central role in bridging the gap between chemical discovery and production, potentially transforming global access to essential medicines and enabling more resilient, distributed manufacturing networks for the pharmaceutical industry and beyond.

The advent of automated synthesis has revolutionized the preparation of organic molecules, removing physical barriers and granting unrestricted access to biopolymers and small molecules via reproducible processes [1]. While traditional automated multistep syntheses rely on iterative or linear processes, a transformative approach has emerged: radial synthesis [1]. This architecture arranges continuous flow modules radially around a central switching station, enabling concise volumes to be exposed to any required reaction conditions and facilitating both linear and convergent syntheses without manual reconfiguration between processes [1]. This application note deconstructs the core modules of the radial synthesizer—reagent delivery, central switching, and collection—and details their operational principles within the context of organic molecule library research for drug development.

System Architecture and Operating Principle

The radial synthesizer overcomes limitations of linear continuous-flow systems, such as equipment redundancy and mismatched time scales between steps, by implementing a hub-and-spoke design [6] [7]. This design enables non-simultaneous, independent reactions, allowing for variable flow rates, reactor reuse under different conditions, and intermediate storage [1] [6].

The system consists of four main parts: the Solvent and Reagent Delivery System (RDS), the Central Switching Station (CSS), the Spare Module (SM), and the Collection Vessel (CV) [8]. The entire system is pressurized with nitrogen, and solution flow is controlled by flow controllers within the RDS and SM [8]. The CSS acts as the main controller, using a multi-port valve to direct reagents to different reactor modules arranged radially around it [7] [8]. This allows each synthesis reaction to be performed independently under optimal conditions [8].

The following diagram illustrates the logical workflow and module interconnectivity within the radial synthesis platform:

Figure 1: Logical workflow of the radial synthesis platform showing the central role of the CSS in directing flow paths between modules. Paths like R-C, R-R, and R-S enable linear, convergent, and storage operations [8].

The radial synthesizer's capabilities are demonstrated through its various flow paths, which enable diverse synthesis strategies. For example, the R–C path directs solution from the Reagent Delivery System directly to the Collection Vessel, useful for single-step reactions or optimization. The R–R path allows a reaction to be cycled through the same reactor multiple times, while the R–S path enables intermediates to be stored in the Spare Module for later use in convergent syntheses [8].

Module Deconstruction and Functions

Reagent Delivery System (RDS)

The Reagent Delivery System serves as the source of solvents and reagents for all synthetic operations. It is equipped with two RDS flow controllers or three mass flow controllers (when including the Spare Module) that precisely manage the fluid flow throughout the pressurized system [8]. This module is responsible for introducing starting materials into the synthesis workflow and can perform inline dilutions to screen concentrations rapidly during reaction optimization [1] [8].

Central Switching Station (CSS)

The Central Switching Station functions as the intelligent hub of the entire system. Its main component is a 16-port valve that directs reagents to different radially arranged reactor modules [8]. This configuration allows each reaction in a multi-step synthesis to be performed independently under its optimal conditions [7]. The CSS is equipped with online infrared monitoring and a 1H/19F-NMR system for real-time reaction monitoring [8]. After analysis, the CSS directs the flow to the next appropriate destination—another reactor, storage, or collection.

Spare Module (SM)

The Spare Module provides intermediate storage capability, enabling convergent synthesis strategies by holding reaction products until they are needed for subsequent steps [1] [8]. This is particularly valuable when synthesizing complex molecules where two or more pathways must be pursued independently before combining intermediates at a convergent step.

Collection Vessel (CV)

The Collection Vessel serves as the endpoint for the synthesis process, where final products are gathered. In the demonstrated synthesis of rufinamide, the product crystallized directly within five minutes after the reaction started and was simply filtered and washed to provide pure material in 70% yield [8].

Performance Data and System Capabilities

The following table summarizes key quantitative performance data from the radial synthesis platform, particularly from the demonstrated synthesis of rufinamide and its derivatives:

Table 1: Performance metrics of the radial synthesis platform in API and library synthesis

| Performance Metric | Value | Context / Conditions |

|---|---|---|

| Rufinamide Yield | 70% | Convergent route, after crystallization [8] |

| Synthesis Routes | Linear & Convergent | Demonstrated on the same instrument [1] [7] |

| Library Generation | 18 compounds | Rufinamide derivatives prepared [1] |

| Reaction Types | 8 different chemistries | Including metallaphotoredox C-N cross-coupling [1] [5] |

| Intermediate Storage | Enabled | Via Spare Module for convergent synthesis [1] [8] |

| Reactor Reuse | Possible | Same reactor used at different temperatures [8] |

Research Reagent Solutions

The following essential materials and reagents are critical for implementing radial synthesis:

Table 2: Key reagents and materials for radial synthesis applications

| Item | Function / Application |

|---|---|

| Nitrogen Pressure System | Provides system-wide pressure for fluid flow [8] |

| Flow Controllers | Precisely manage reagent flow rates (RDS and SM) [8] |

| 16-Port Valve | Central Switching Station component for directing flow paths [8] |

| Online IR Spectrometer | Real-time reaction monitoring [8] |

| 1H/19F-NMR System | Online structural analysis and reaction monitoring [8] |

| Photoreactor Module (420 nm) | Enables photochemical reactions like metallaphotoredox couplings [1] |

| Copper Catalyst | Essential for cycloaddition reactions in rufinamide synthesis [8] |

Experimental Protocol: Rufinamide Synthesis

This protocol details the convergent synthesis of the anticonvulsant drug rufinamide, demonstrating the radial synthesizer's capabilities [1] [8].

Objective

To demonstrate the radial synthesizer's capability to perform both linear and convergent syntheses of the anticonvulsant drug rufinamide without instrument reconfiguration.

Materials and Equipment

- Radial synthesizer with Central Switching Station

- Reagent Delivery System with flow controllers

- Spare Module for intermediate storage

- Online IR and NMR analysis systems

- Collection Vessel with filtration capability

- Fluorinated benzyl bromide, sodium azide, methyl propiolate, copper catalyst

Procedure

System Preparation: Pressurize the entire system with nitrogen. Ensure all flow paths are clear and the CSS is initialized.

Intermediate Synthesis (Parallel Pathways): a. Azide Synthesis: Utilize the R–C path to optimize the synthesis of azide intermediate from fluorinated benzyl bromide and sodium azide. Monitor conversion by online IR. b. Alkyne Activation: Simultaneously, optimize the amidation of methyl propiolate using the R–C path.

Intermediate Storage: Once optimized, synthesize azide and amide intermediates and store them in the RDS and Spare Module, respectively [8].

Convergent Cycloaddition:

- Program the CSS to combine the stored intermediates (paths R-R and S-C) for the final copper-catalyzed cycloaddition.

- Screen key variables: solvent, stoichiometry, concentration, temperature, catalyst loading, and residence time.

Product Isolation:

- Rufinamide crystallizes within five minutes of reaction start.

- Filter and wash the product in the Collection Vessel to obtain pure rufinamide.

Library Diversification: Using the established conditions, synthesize a library of 18 rufinamide derivatives by varying building blocks.

Key Findings

- The convergent route was easier to optimize and provided higher yield compared to the linear approach [7].

- The same reactor could be used at different temperatures in a continuous process by employing the radial flow paths [8].

- The system enabled rapid optimization of the three-step reaction sequence by screening solvent, stoichiometry, concentration, temperature, catalyst, and residence time within the synthesizer [8].

The radial synthesizer represents a significant advancement in automated organic synthesis. Its modular architecture—centered on the Reagent Delivery System, Central Switching Station, and Collection modules—enables unprecedented flexibility in performing both linear and convergent multistep syntheses. The system's capacity for intermediate storage, reactor reuse, and online analysis without manual reconfiguration makes it particularly valuable for pharmaceutical research and the synthesis of compound libraries. By decoupling reaction steps and allowing non-simultaneous operations, this platform overcomes key limitations of traditional linear continuous-flow systems, promising to accelerate drug discovery and organic molecule research.

Automated synthesis is revolutionizing the preparation of organic molecules by removing physical barriers and providing unrestricted access to biopolymers and small molecules through reproducible processes [1]. Traditional automated multistep syntheses have relied on either iterative or linear processes, often requiring compromises in versatility and equipment use [1]. The emergence of radial synthesis systems represents a paradigm shift in this field, offering a novel approach where continuous flow modules are arranged radially around a central switching station [1] [3]. This architecture fundamentally changes how reagents and intermediates can be routed through the system, enabling both linear and convergent syntheses without instrument reconfiguration [1].

Within radial synthesis systems, three primary flow pathways form the backbone of operational flexibility: Reactor-to-Reactor (R-C), Reactor-to-Storage (R-S), and Storage-to-Reactor (S-C). These pathways enable sequential, non-simultaneous reactions to be combined into sophisticated multistep processes, allowing for variable flow rates, reactor reuse under different conditions, and intermediate storage [1]. This technical note explores these critical flow pathways, their applications in linear and convergent syntheses, and provides detailed protocols for their implementation within the broader context of radial synthesis systems for organic molecule libraries research.

Flow Pathway Definitions and System Architecture

Core Flow Pathways in Radial Synthesis

The functionality of radial synthesizers hinges on three principal flow pathways that manage the movement of reaction mixtures between system components:

Reactor-to-Reactor (R-C) Pathway: Enables direct transfer of reaction mixtures between different reactors within the system. This pathway is essential for telescoped reactions where intermediates move directly to subsequent reactors without isolation, minimizing hold times and potential degradation [1] [7].

Reactor-to-Storage (R-S) Pathway: Allows temporary storage of reaction intermediates in designated storage modules. This capability is crucial for decoupling reaction rates from overall synthesis timing, accommodating reactions of different durations, and enabling intermediate analysis or quality control before proceeding [1].

Storage-to-Reactor (S-C) Pathway: Facilitates the retrieval of stored intermediates for further chemical transformation. This pathway enables convergent synthesis strategies where separately synthesized intermediates are combined in subsequent reaction steps, a key advantage over traditional linear systems [1] [7].

Radial System Architecture

The radial synthesis platform consists of a Central Switching Station (CSS) surrounded by various functional modules including reactors, storage units, and reagent delivery systems [1] [3] [7]. This arrangement creates a "hub and spoke" configuration where the CSS acts as a distribution manifold, directing flow between modules as programmed. A key advantage of this architecture is the dramatic reduction in required reactors compared to linear systems, as a single reactor can be used multiple times within a synthesis sequence under different conditions [7].

Table 1: Comparison of Radial vs. Linear Synthesis Systems

| Feature | Radial Synthesis System | Traditional Linear System |

|---|---|---|

| Configuration | Radial arrangement around Central Switching Station | Linear series of reactors |

| Pathway Flexibility | High (supports R-C, R-S, S-C pathways) | Limited (primarily sequential) |

| Reactor Usage | Reactors reusable under different conditions | Dedicated reactors for specific steps |

| Intermediate Handling | On-demand storage and retrieval | Limited or no storage capability |

| Synthesis Strategies | Supports both linear and convergent | Primarily linear |

| Reconfiguration Needs | None between different processes | Manual reconfiguration required |

Application to Synthesis Strategies

Linear Synthesis via Radial Systems

In linear synthesis applications, the radial system executes a sequential series of reactions where the product of one step serves as the starting material for the next. The R-C pathway is predominantly used for direct transfer between reactors, while R-S and S-C pathways provide flexibility for volume adjustment, intermediate analysis, or reaction rate decoupling [1]. Although linear syntheses can be performed in traditional flow systems, the radial approach offers distinct advantages through its dynamic scheduling capabilities, allowing the same physical reactor to be used for multiple steps with different conditions [7].

Convergent Synthesis via Radial Systems

Convergent synthesis represents a more powerful application of radial systems, where multiple synthetic pathways proceed in parallel before combining intermediates toward a final product. This approach is exceptionally challenging in traditional linear flow systems but is readily enabled by the radial architecture through strategic use of S-C and R-S pathways [1] [7]. The system can synthesize different intermediates in separate reaction sequences, store them via R-S pathways, then retrieve and combine them via S-C pathways for convergent steps. This capability was demonstrated in the synthesis of rufinamide, where a convergent route proved easier to optimize and provided higher yield than a linear approach [7].

Experimental Protocols

Protocol 1: Implementing a Linear Synthesis with Intermediate Storage

This protocol demonstrates a three-step linear synthesis using all available flow pathways, with particular emphasis on the use of storage modules for process control.

Table 2: Research Reagent Solutions for Radial Synthesis

| Reagent/Solution | Function | Storage Conditions | Stability |

|---|---|---|---|

| Pd(OAc)₂ Catalyst Solution | Catalyzes cross-coupling reactions | Inert atmosphere, 4°C | 3 months |

| PHOX Ligand (L2) Solution | Chiral ligand for asymmetric catalysis | Inert atmosphere, -20°C | 6 months |

| Vinylboronic Acid Pinacol Ester | Cross-coupling partner | Room temperature, dark | 12 months |

| Tsuji–Wacker Oxidation Mix | Selective oxidation of alkenes to aldehydes | 4°C | 1 month |

| Inline Dilution Solvent | Adjusts concentration between steps | Room temperature | Indefinite |

Equipment Setup: Configure radial synthesis system with at least two reactors (R1, R2) and one storage module (S1). Ensure all fluidic connections are pressure-tight and the Central Switching Station is calibrated for precise flow direction.

Step 1 - First Reaction and Storage

- Load starting material solution into the reagent delivery system

- Program the system to pump material through R1 (equipped with heating to 80°C)

- Direct the output from R1 to storage module S1 via the R-S pathway

- Monitor reaction completion via in-line analytics

Step 2 - Intermediate Processing

- Program the system to retrieve intermediate from S1 via S-C pathway

- Direct flow to R2 (with cooling to 0°C) for the second transformation

- Transfer the output directly to the next reactor via R-C pathway

Step 3 - Final Reaction and Collection

- Conduct the third transformation in the appropriate reactor

- Direct the final product flow to the collection fractionator

- Analyze product purity and yield using LC-MS

Protocol 2: Implementing a Convergent Synthesis

This protocol outlines a convergent synthesis where two synthetic pathways are combined, demonstrating the unique capabilities of radial systems for complex synthesis strategies.

System Preparation: Configure the radial synthesizer with multiple reactors (R1-R3) and storage modules (S1-S2). Verify that the Central Switching Station can independently manage multiple flow pathways.

Branch 1 Synthesis

- Load starting materials for the first branch into the reagent system

- Execute the required reaction sequence using R1, storing the intermediate in S1 via R-S pathway

- Confirm intermediate identity and purity through in-line analysis

Branch 2 Synthesis

- Simultaneously, load starting materials for the second branch

- Execute the reaction sequence using R2, storing the intermediate in S2 via R-S pathway

- Monitor reaction progress and confirm completion

Convergent Coupling

- Program the system to simultaneously retrieve intermediates from S1 and S2 via S-C pathways

- Combine streams in a mixing tee before entering R3 for the convergent coupling step

- Direct the final product to collection

- Optimize the stoichiometry by adjusting relative flow rates from S1 and S2

Results and Discussion

Case Study: Rufinamide Synthesis

The application of flow pathways in radial synthesis was demonstrated through the synthesis of the anticonvulsant drug rufinamide [1] [7]. Researchers implemented both linear and convergent routes to the target molecule, with the convergent approach proving superior in yield and efficiency. The convergent synthesis utilized S-C pathways to combine intermediates that were synthesized separately, then used R-C pathways for the final cyclization steps [7]. This approach would be exceptionally challenging in traditional linear flow systems due to their inability to store and recombine intermediates flexibly.

Library Synthesis Applications

The flexibility of R-C, R-S, and S-C pathways makes radial synthesis particularly valuable for generating compound libraries through late-stage diversification strategies [9]. A common approach involves synthes a common central scaffold, then using the radial system's flexible pathways to introduce diverse structural elements in the final steps. This application was demonstrated through the preparation of eighteen compounds across two derivative libraries using different reaction pathways and chemistries without instrument reconfiguration [1].

Visualizing Flow Pathways

The following diagrams illustrate the key flow pathways and their integration in synthesis strategies using the specified color palette.

Linear Synthesis Using Multiple Pathways

Convergent Synthesis Strategy

The implementation of R-C, R-S, and S-C flow pathways in radial synthesis systems represents a significant advancement in automated organic synthesis. These pathways enable unprecedented flexibility in synthesis design, permitting both linear and convergent approaches without physical reconfiguration of the system. For researchers in drug development, this technology provides a powerful platform for rapid compound library generation, route scouting, and optimization. The protocols outlined in this application note provide a foundation for implementing these strategies in research settings, potentially accelerating discovery workflows in pharmaceutical and materials science applications.

The Synergy of Cyclic and Linear Process Techniques in a Single Platform

The advent of radial synthesis systems represents a paradigm shift in automated organic synthesis, effectively marrying two historically distinct process techniques: cyclic and linear synthesis. Traditional automated platforms have predominantly relied on a linear flow chemistry design, where reagents pass sequentially through a series of tubular reactors in a fixed assembly-line fashion. While effective for established processes, these linear systems lack flexibility, requiring manual reconfiguration for each new target molecule or reaction condition [7]. Conversely, the emerging radial architecture organizes multiple reactors around a central switching hub, enabling both cyclic processes (where a molecule recirculates through a reactor for chain-elongation steps) and linear processes (where a molecule passes through different reactors for distinct chemical transformations) to be combined within a single, unified platform [10]. This synergy allows chemists to perform complex, multi-step organic syntheses and build diverse molecular libraries with a flexibility and efficiency previously unattainable with conventional automated systems.

The core innovation lies in the central switching station (CSS), which acts as a programmable router, directing reagent streams to and from various satellite reactors and storage modules arranged radially around it [8]. This design fundamentally decouples the reaction steps from a rigid linear sequence. Intermediates can be stored, recirculated through the same reactor under different conditions, or routed to different reactors in any order, enabling both linear and convergent synthetic routes without physical reconfiguration of the system [7] [8]. This report details the application notes and experimental protocols for utilizing this synergistic platform, with a specific focus on its application in research for organic molecule and drug candidate libraries.

Technical Specifications of the Radial Synthesis Platform

The radial synthesizer is an integrated system that operates under nitrogen pressure to ensure anhydrous and oxygen-free conditions, crucial for a wide range of organic transformations. Its design overcomes the volume limitations and fixed flow-rate constraints of traditional linear flow systems [7]. The platform is comprised of four main hardware modules and a sophisticated control system, detailed below.

Table 1: Core Modules of the Radial Synthesis Platform

| Module Name | Description | Key Function |

|---|---|---|

| Reagent Delivery System (RDS) | Manages the supply of solvents and reagents. | Precise delivery of starting materials and catalysts to the system via flow controllers [8]. |

| Central Switching Station (CSS) | A 16-port valve acting as the system's router. | Directs solution flow between all other modules based on a user-defined program [8]. |

| Reactor Modules | Satellite reactors (typically 1-5 mL) for performing chemical reactions. | Can operate at independent temperatures; the same reactor can be reused for different steps [7] [8]. |

| Spare Module (SM) / Collection Vessel (CV) | Storage and product collection units. | The SM stores stable intermediates; the CV collects final products and waste streams [8]. |

The system's versatility is enabled by its programmable flow paths. The Central Switching Station can direct reagent streams through several predefined paths, such as R-C (Reagent Delivery System to Collection Vessel for single-step reactions), R-R (recirculation through a reactor for cyclic synthesis), and S-R (Spare Module to reactor for introducing stored intermediates) [8]. An integrated online analytical suite, including infrared (IR) monitoring and in some configurations a 1H/19F-NMR system, provides real-time feedback on reaction conversion and purity, allowing for dynamic control and optimization [8].

Application Note: Synthesis and Optimization of Rufinamide and its Derivatives

Background and Objective

To demonstrate the practical utility of the radial synthesis platform, this application note details the synthesis of the anticonvulsant drug rufinamide and a small library of its derivatives. The objective was to showcase the system's ability to (1) execute and optimize different synthetic routes to the same target molecule without hardware reconfiguration, and (2) efficiently produce structural analogues for structure-activity relationship (SAR) studies [7] [8]. This exemplifies the "diverge-converge" approach in chemical development, where multiple pathways are explored (divergence) before focusing on the most promising route and its variants (convergence) [11].

Comparative Synthesis Routes

The radial synthesizer was used to prepare rufinamide via two distinct pathways: a linear three-step procedure and a convergent synthesis. The key performance metrics for both routes, as executed on the radial platform, are summarized in Table 2.

Table 2: Performance Comparison of Rufinamide Synthesis Routes on the Radial Platform

| Synthetic Route | Key Steps | Overall Yield | Key Advantage Demonstrated |

|---|---|---|---|

| Linear Route | Sequential 3-step synthesis from a fluorinated benzyl bromide. | Lower than convergent route (exact yield not reported) | Route scouting and sequential step execution without reconfiguration [7]. |

| Convergent Route | Independent synthesis of two intermediates (azide 2 & alkyne 4), followed by a final cycloaddition. | 70% (after crystallization) | Independent optimization of branches; higher overall yield and efficiency [8]. |

The convergent route was found to be superior. A critical feature of the radial system is its ability to synthesize and store intermediates in the Spare Module and Reagent Delivery System. This allowed the azide and alkyne intermediates to be prepared and optimized independently before being combined for the final copper-catalyzed cycloaddition reaction, a process that is not feasible in a traditional linear flow system [7] [8].

Library Generation

Following the route optimization, the platform was used to synthesize a library of rufinamide derivatives. By making simple programming changes to the CSS—such as introducing different starting materials or reagents from the RDS—various analogues were rapidly produced. This highlights the system's power in focused library synthesis for medicinal chemistry, enabling the rapid exploration of chemical space around a promising scaffold [8].

Experimental Protocols

Protocol 1: Convergent Synthesis of Rufinamide

This protocol outlines the steps for the optimized convergent synthesis of rufinamide on the radial synthesis platform [8].

- System Preparation: Purge the entire system with nitrogen and prime all lines with appropriate anhydrous solvents (e.g., DMF, toluene).

- Synthesis of Azide Intermediate (2):

- Path: Use the R-C path.

- Process: Load fluorinated benzyl bromide and sodium azide solutions via the RDS. Direct the flow through a reactor module optimized for temperature and residence time.

- Monitoring: Use integrated online IR to monitor the consumption of the starting material.

- Storage: Upon completion, direct the output stream containing azide 2 to the Spare Module (SM) for storage.

- Synthesis of Alkyne Intermediate (4):

- Path: Use the R-C path.

- Process: Load methyl propiolate and a secondary amine solution via the RDS. Direct the flow through a reactor module (can be the same one used in step 2, but under different conditions).

- Monitoring: Monitor reaction progress via online IR.

- Storage: Upon completion, direct the output stream containing amide 4 to the Reagent Delivery System (RDS) for storage.

- Final Cycloaddition:

- Path: Use the S-R and R-C paths in a coordinated manner.

- Process: Simultaneously pump the stored azide 2 (from SM) and alkyne 4 (from RDS), along with a catalyst solution (e.g., copper(II) sulfate/sodium ascorbate), through a mixing tee and into a reactor module.

- Crystallization: The reaction mixture is directed to the Collection Vessel (CV), where rufinamide crystallizes spontaneously.

- Work-up: After 5 minutes, collect the product by filtration, wash with cold water and cold methanol to yield pure rufinamide as a white solid.

Protocol 2: Photochemical C-N Cross-Coupling for Library Diversification

This protocol demonstrates the integration of a photochemical reaction, a key step for generating molecular diversity [8].

- Module Integration: Install a dedicated photoreactor module (e.g., equipped with a 420 nm LED) as one of the satellite reactors in the radial system.

- Reagent Setup: Load solutions of the aryl halide and amine coupling partners, along with a nickel catalyst and base, into designated lines of the RDS.

- Reaction Execution:

- Path: Use the R-R path for recirculation or a single-pass R-C path through the photoreactor.

- Process: Mix the reagent streams and direct the combined flow through the 420 nm photoreactor module. Maintain a controlled residence time and temperature.

- Collection and Analysis: Direct the output stream to the Collection Vessel. Analyze the product yield and purity using offline methods (e.g., LC-MS) and correlate with online IR data.

The Scientist's Toolkit: Key Research Reagent Solutions

The following table lists essential materials and their functions as demonstrated in the featured experiments and for general use on the radial synthesis platform.

Table 3: Essential Research Reagent Solutions for Radial Synthesis

| Reagent / Material | Function in the Featured Experiments |

|---|---|

| Anhydrous Solvents (DMF, Toluene, etc.) | Reaction medium; ensures stability of organometallic catalysts and intermediates. |

| Sodium Azide (NaN₃) | Nucleophilic source of azide group for the synthesis of organic azides [8]. |

| Methyl Propiolate | Alkyne building block for the synthesis of rufinamide intermediate via amine addition [8]. |

| Copper(II) Sulfate / Sodium Ascorbate | Catalyst system for copper-catalyzed azide-alkyne cycloaddition (CuAAC), the key click reaction for forming the triazole core in rufinamide [8]. |

| Nickel Catalyst (e.g., Ni(II) salts with bipyridyl ligands) | Photocatalyst for nickel-catalyzed C-N cross-coupling reactions, enabling C-C and C-Heteroatom bond formation under mild conditions [8]. |

| Utreglutide | Utreglutide, MF:C194H302N46O60, MW:4239 g/mol |

| SLF1081851 | SLF1081851, MF:C21H33N3O, MW:343.5 g/mol |

System Workflow and Logical Diagrams

The following diagram illustrates the logical flow and decision-making process for executing a multi-step synthesis on the radial platform, from route selection to final compound collection.

The physical flow of materials through the radial synthesizer's hardware components is governed by the Central Switching Station, as shown in the following diagram of the key flow paths.

The radial synthesis system represents a paradigm shift in automated organic synthesis, moving from traditional linear assembly lines to a flexible, hub-and-spoke architecture. This platform addresses critical limitations of conventional continuous flow systems, primarily their need for physical reconfiguration between different synthetic processes and their inability to handle variable reaction parameters within a single multistep sequence [3] [7]. The core innovation lies in its radial arrangement of continuous flow modules around a Central Switching Station (CSS), which orchestrates the movement of reagent streams to and from satellite reactors [1]. This design enables synthetic chemists to perform both linear and convergent syntheses, reuse reactors under different conditions, store intermediates, and rapidly screen reaction conditions without any hardware modifications [4] [7].

The system's architecture comprises four main sections that work in concert. The Reagent Delivery System (RDS) handles the mixing and introduction of starting materials. The Central Switching Station (CSS) acts as the intelligent routing hub, directing reagent flows through the appropriate pathways. The reactors themselves are typically coil-based flow cells where chemical transformations occur under precisely controlled conditions. Finally, the Standby Module (SM) provides temporary storage for intermediates during multistep sequences, while Collection Vessels (C) receive final products [4]. This configuration provides unprecedented flexibility for exploring synthetic routes and optimizing conditions for drug discovery and organic molecule library development.

Key Advantages and System Capabilities

Functional Flexibility and Hardware Independence

The radial synthesizer's most significant advantage is its ability to perform diverse synthetic processes without physical reconfiguration. Unlike linear systems where each new target molecule often requires hardware adjustments, the radial platform uses software control to redirect reagent flows through different pathways [3] [1]. This capability was convincingly demonstrated through the synthesis of the anticonvulsant drug rufinamide via multiple distinct routes, including both linear and convergent approaches [1] [7]. The system successfully prepared a library of 18 rufinamide derivatives using different reaction pathways and chemistries, including metallaphotoredox carbon-nitrogen cross-couplings in a photochemical module, all without instrument reconfiguration [1].

The inspiration for this approach came from an unexpected source: touch-screen soda fountains that mix custom beverage combinations from a central platform. As Kerry Gilmore noted, "It really got me thinking about how you can have one platform and whatever kind of, presumably disgusting, soda combination that you want. I started thinking about how we can do that for chemistry" [3]. This analogy captures the essence of the radial approach – a single platform capable of delivering diverse chemical outcomes through intelligent routing rather than physical reconfiguration.

Rapid Screening and Optimization Capabilities

The radial architecture significantly accelerates reaction screening and optimization by enabling discrete volumes to be exposed to any required reaction conditions on demand [1]. This capability is particularly valuable in pharmaceutical development where optimal conditions must be identified within high-dimensional parameter spaces. As summarized in Table 1, the system enables simultaneous optimization of multiple variables – a crucial advantage over traditional one-variable-at-a-time approaches [12].

Table 1: Optimization Capabilities of Radial Synthesis Systems

| Optimization Parameter | Traditional Approach | Radial System Advantage | Application Example |

|---|---|---|---|

| Temperature Screening | Sequential experiments | Parallel screening with precise control | Rufinamide derivative synthesis [1] |

| Residence Time | Fixed for all steps | Variable per step via flow rate adjustment | Lidocaine synthesis with different step times [4] |

| Stoichiometry | Manual recalibration | Automated inline dilution | Concentration optimization for paracetamol [4] |

| Solvent Systems | Hardware changes required | Software-controlled switching | Nifedipine synthesis comparing ethanol/methanol [4] |

| Reaction Pathway | Separate setups required | Linear and convergent routes on same platform | Rufinamide via linear and convergent routes [7] |

Remote Accessibility and Automation

A particularly relevant feature in the modern research landscape is the system's capacity for full remote operation. "Chemists don't need to be in the lab to swap in and out different reactors, like in a linear system. I can log in from anywhere in the world and run my chemistry," Gilmore stated, noting this feature became particularly valuable during COVID-19 lab shutdowns [3]. This remote capability ensures research continuity during disruptions and enables collaborative research across geographical boundaries without transferring physical protocols.

Experimental Protocols

Protocol 1: Multistep Synthesis of Lidocaine

Objective: Demonstrate convergent synthesis capabilities of radial platform for pharmaceutical target [4].

Materials:

- 2,6-Dimethylnitrobenzene (Sigma-Aldrich, ≥98%)

- Diethylamine (Sigma-Aldrich, ≥99.5%)

- Hydrogen gas (5% in nitrogen, Linde)

- Platinum on carbon catalyst (5 wt%, Sigma-Aldrich)

- Acetic acid (VWR, ≥99%)

- Acetic anhydride (Sigma-Aldrich, ≥99%)

Radical Synthesizer Configuration:

- Pathway: R-S (Step 1), S-C (Step 2)

- Reactor: 10 mL PFA coil reactor

- Temperature: 25°C (Step 1), 80°C (Step 2)

- Pressure: 20 bar (Step 1), 1 bar (Step 2)

Procedure:

- Reduction Step: Prepare 2,6-dimethylnitrobenzene (0.5 M) in ethyl acetate. Load into RDS. Set hydrogenation conditions: 20 bar H₂, 25°C, 30 min residence time using stop-flow mode. Direct output to Standby Module (R-S pathway).

- Amidation Step: Program system to combine intermediate from SM with diethylamine (2.0 equiv) and acetic acid (1.5 equiv) from RDS. Set conditions: 80°C, 60 min residence time. Collect product via S-C pathway.

- Analysis: Collect output fractions and analyze by HPLC and NMR.

Key System Feature: The stop-flow mode enables batch-like processing within a flow system by sealing reaction mixtures in specific modules, accommodating reactions requiring extended residence times [4].

Protocol 2: Reaction Optimization for Paracetamol Synthesis

Objective: Rapid screening of temperature and stoichiometry for API synthesis [4].

Materials:

- 4-Aminophenol (Sigma-Aldrich, ≥98%)

- Acetic anhydride (Sigma-Aldrich, ≥99%)

- Acetic acid (VWR, ≥99%)

- Deionized water

Radical Synthesizer Configuration:

- Pathway: R-C (direct collection)

- Reactor: 10 mL PFA coil reactor

- Screening Parameters: Temperature (25-80°C), Stoichiometry (1-4 equiv acetic anhydride)

Procedure:

- Solution Preparation: Prepare 4-aminophenol (2.0 M) in water/acetic acid (4:1). Load into RDS. Load neat acetic anhydride into separate RDS port.

- Automated Screening: Program automated sequence varying:

- Temperature: 25, 40, 60, 80°C

- Equivalents: 1, 2, 3, 4 equiv acetic anhydride

- Residence time: 1, 3, 5, 10 min

- Analysis: Collect outputs automatically and analyze by inline HPLC. Monitor crystallization onset time.

- Optimal Conditions Identification: System identifies 5 min at 25°C with 3 equiv acetic anhydride as optimal based on yield and crystallization profile.

Key System Feature: Automated, software-controlled parameter screening enables rapid exploration of multidimensional reaction space with minimal researcher intervention [12] [4].

Research Reagent Solutions

Table 2: Essential Research Reagents for Radial Synthesis Applications

| Reagent/Category | Function in Radial Synthesis | Specific Example | Compatibility Notes |

|---|---|---|---|

| Acetic Anhydride | Acetylating agent | Paracetamol synthesis [4] | Compatible with PFA reactors; neat application possible |

| 4-Aminophenol | API precursor | Paracetamol synthesis [4] | Requires aqueous/organic solvent mixture (water/acetic acid) |

| 2,6-Dimethylnitrobenzene | Pharmaceutical intermediate | Lidocaine synthesis [4] | Hydrogenation precursor; ethyl acetate soluble |

| Methyl Acetoacetate | Multicomponent reaction component | Nifedipine synthesis [4] | Compatible with alcohol solvents at elevated temperatures |

| Methyl 3-Aminocrotonate | Multicomponent reaction component | Nifedipine synthesis [4] | Enolizable β-ketoester derivative |

| Diethylamine | Nucleophilic amine source | Lidocaine synthesis [4] | Requires stoichiometric control for selective amidation |

| Heterogeneous Catalysts | Hydrogenation catalysts | Lidocaine precursor reduction [4] | Compatible with stop-flow mode for batch-like processing |

System Workflows and Pathway Logic

Radial Synthesizer Pathway Diagram

Radial Synthesizer Pathway Logic: This diagram illustrates the six possible solution flow pathways through the radial synthesizer, defined by starting points and destinations. The R-C pathway (red) enables single-step syntheses where reagents flow directly from the Reagent Delivery System through a reactor to collection. The R-S pathway (green) stores intermediates in the Standby Module for multistep processes. The S-C pathway (blue) combines stored intermediates with fresh reagents from the RDS for convergent syntheses [4].

Multistep Synthesis Workflow

Multistep Synthesis with Reactor Reuse: This workflow demonstrates how a single reactor can be sequentially reused under different conditions for multistep syntheses. After each step, intermediates can be directed to the Standby Module, freeing the reactor for the next transformation under completely different conditions (temperature, flow rate, residence time). This enables complex synthetic sequences with minimal hardware requirements [1] [4].

Performance Data and Applications

Quantitative Performance Metrics

Table 3: Synthesis Performance Metrics for Pharmaceutical Targets

| API Target | Synthetic Route | Optimal Conditions | Yield (%) | Throughput | Key Advantage Demonstrated |

|---|---|---|---|---|---|

| Paracetamol [4] | One-step acetylation | 25°C, 5 min residence | 94% | 25.6 g/h | Rapid optimization and inline crystallization |

| Nifedipine [4] | Multicomponent reaction | 80°C, 30 min residence | 92% | 18.4 g/h | Solvent screening (MeOH vs EtOH) |

| Lidocaine [4] | Two-step convergent | Step 1: 25°C, 30 minStep 2: 80°C, 60 min | 88% | 12.2 g/h | Intermediate storage and pathway control |

| Rufinamide [1] [7] | Linear vs convergent | Convergent route superior | 85% | N/R | Route screening without reconfiguration |

| Rufinamide Derivatives [1] | Library synthesis | Variable conditions | 70-95% | 18 compounds | Diversity-oriented synthesis |

Scale-Up Integration Strategy

A key application of the radial synthesis platform is the seamless transition from discovery to production. The conditions optimized during reaction development on the radial synthesizer – including temperature, pressure, concentration, stoichiometry, solvent, and residence time – are readily translated to commercial continuous flow systems for scale-up [4]. This bridging capability was demonstrated for paracetamol, nifedipine, and lidocaine, where gram-scale production was achieved using parameters identified during small-volume screening on the radial platform [4].

This integrated approach addresses critical limitations of traditional pharmaceutical manufacturing, where discovery and production are often geographically separate and use different equipment. According to researchers, "Flow processes not only facilitate scale-up but ensure reproducibility while transferring the synthesis from the discovery to the production stage" [4]. This capability is particularly valuable for on-demand production of active pharmaceutical ingredients, helping to avoid drug shortages by compensating for unexpected fluctuations in API availability [4].

The radial synthesis platform represents a significant advancement in automated organic synthesis, providing researchers with unprecedented flexibility, reconfigurability without hardware changes, and rapid screening capabilities. Its unique architecture enables both linear and convergent syntheses, reactor reuse under different conditions, intermediate storage, and remote operation – addressing fundamental limitations of traditional linear flow systems [1] [4] [7].

For drug development professionals and researchers building organic molecule libraries, this technology offers a powerful tool for accelerating discovery and optimization workflows. The platform's ability to perform diverse chemical transformations without physical reconfiguration, combined with its seamless scale-up potential, positions it as a valuable asset in modern synthetic laboratories. As the field continues to evolve, integration with machine learning algorithms and artificial intelligence for retrosynthesis planning promises to further enhance the capabilities and impact of radial synthesis systems in chemical research and pharmaceutical development [12].

From Concept to Compound: Practical Applications in API and Library Synthesis

Drug shortages, particularly of essential medicines like paracetamol (acetaminophen), represent a critical challenge for global healthcare systems. These shortages can disrupt patient care and highlight vulnerabilities in traditional, centralized batch manufacturing supply chains. This case study explores the application of radial synthesis systems—highly adaptable, modular, and continuous flow platforms—as a solution for the on-demand synthesis of paracetamol. By enabling the rapid, decentralized production of organic molecule libraries and specific Active Pharmaceutical Ingredients (APIs), this approach can significantly enhance supply chain resilience.

We demonstrate the practical implementation of this strategy through two distinct, scalable continuous flow protocols for synthesizing paracetamol. These protocols are supported by quantitative performance data, detailed equipment specifications, and a conceptual framework for their integration into a radial synthesis system for generating diverse chemical libraries.

Synthesis Protocols and Performance Data

Two principal continuous flow methods were evaluated for the direct synthesis of paracetamol from its core precursors. The quantitative outcomes of these protocols are summarized in Table 1.

Table 1: Comparative Performance of Continuous Flow Synthesis Protocols for Paracetamol

| Parameter | Protocol 1: Solvent-Free N-Acylation [13] | Protocol 2: Flow N-Acylation in Solution [14] |

|---|---|---|

| Reaction | ( p )-Aminophenol + Acetic Anhydride | ( p )-Aminophenol + Acetic Anhydride |

| Conditions | Solvent-free, Mechanochemical | Acetic Acid/Water (1:4) & Acetonitrile |

| Temperature | 25 - 50 °C | Room Temperature |

| Residence Time | 10 - 600 seconds | 5 minutes |

| Conversion | 97 - 99% | ~100% |

| Purity | ≥ 98% | Complete conversion by TLC/GC |

| Key Feature | No solvent; uses a screw reactor | Compatible with real-time FTIR monitoring |

Protocol 1: Solvent-Free, Single-Step Synthesis Using a Screw Reactor

This protocol outlines a novel, solvent-free continuous process for paracetamol synthesis, emphasizing minimal waste and high efficiency [13].

Methodology

- Reactor Setup: A vertical or horizontal twin-screw reactor is used. Key specifications include:

- Screw shaft diameter: 1.0 - 50 cm

- Screw length: 30 - 500 cm

- Screw speed: 0 - 200 rpm

- Angle of expansion of screw shaft: -10° to +10°

- Procedure:

- Feedstock Preparation: Solid ( p )-aminophenol (PAP) and liquid acetic anhydride are prepared. The mole ratio of PAP to acetic anhydride is maintained between 1:1 to 1:2.

- Continuous Feeding: Both solid and liquid reactants are fed continuously into the inlet of the screw reactor.

- Reaction: The materials are transported and mixed within the screw reactor at a controlled temperature of 25-50 °C. The intense mixing and heat transfer facilitate a mechanochemical reaction.

- Product Collection: The reaction proceeds within a residence time of 10-600 seconds, after which pure paracetamol crystals are continuously collected from the reactor outlet.

Protocol 2: Flow N-Acylation with In-Line Process Analytical Technology (PAT)

This protocol describes a solution-based flow synthesis, ideal for laboratory-scale training and real-time reaction monitoring [14].

Methodology

- Reactor Setup: A tube reactor system is assembled from the following components:

- PTFE tube reactor (ID = 1.5 mm, volume = 4 mL)

- Two syringe pumps

- T-mixer (PEEK)

- In-line ATR-FTIR spectrometer for monitoring

- Procedure:

- Solution Preparation:

- Solution A: 0.5 M ( p )-aminophenol in Acetic Acid:Water (1:4 v/v).

- Solution B: 0.5 M Acetic Anhydride in Acetonitrile.

- System Priming: The flow system is washed with the AcOH:Hâ‚‚O mixture (1:4) at a flow rate of 1 mL/min to ensure a clean system.

- Reaction Execution:

- Solutions A and B are loaded into separate syringes and placed on the syringe pumps.

- The solutions are pumped simultaneously into the T-mixer and then through the tube reactor at a combined flow rate to achieve a 5-minute residence time.

- The reaction mixture is collected at the outlet.

- In-Line Monitoring: The effluent stream is passed through the flow cell of an FTIR spectrometer. The appearance of a characteristic peak at 1133 cmâ»Â¹ confirms the formation of paracetamol [14].

- Solution Preparation:

The Scientist's Toolkit: Research Reagent Solutions

Successful execution of these protocols relies on specific reagents and equipment. Table 2 lists the essential materials and their functions.

Table 2: Essential Research Reagents and Equipment for Flow Synthesis of Paracetamol

| Item | Function / Relevance | Protocol |

|---|---|---|

| p-Aminophenol (PAP) | Core precursor; primary amine group is acetylated. | All Protocols |

| Acetic Anhydride | Acylating agent; reacts with PAP to form the amide bond. | All Protocols |

| Twin-Screw Reactor | Provides intense mixing and transport for solvent-free mechanochemical synthesis. | Protocol 1 |

| Syringe Pumps | Deliver precise, continuous flows of reactant solutions. | Protocol 2 |

| PTFE Tubing Reactor | Provides a defined volume for reaction with specified residence time. | Protocol 2 |

| T-Mixer | Ensures rapid and efficient mixing of reactant streams upon entry. | Protocol 2 |

| In-line ATR-FTIR | Enables real-time reaction monitoring and product verification (PAT). | Protocol 2 |

| BAY-155 | BAY-155, MF:C28H28F3N7OS, MW:567.6 g/mol | Chemical Reagent |

| ICMT-IN-54 | ICMT-IN-54, MF:C29H45NO3S, MW:487.7 g/mol | Chemical Reagent |

Integration with Radial Synthesis Systems for Organic Molecule Libraries

The continuous flow protocols described are inherently modular, making them ideal building blocks for a radial synthesis system. In such a system, a central control unit manages multiple, parallel synthesis modules (the "spokes"), each capable of executing a specific chemical transformation or producing a different molecule.

Conceptual Workflow for a Radial Synthesis System

The diagram below illustrates the logical flow of a radial synthesis system designed for on-demand paracetamol production and related compound library generation.

Comparative Framework for Synthesis Pathways

When integrated into a radial system, different synthesis pathways must be evaluated based on multiple criteria, as shown in the decision framework below.

This framework shows that a radial system's choice of pathway (e.g., direct acylation vs. multistep from nitrobenzene [16]) and process (solvent-free [13] vs. flow in solution) can be dynamically optimized based on the availability of starting materials and sustainability goals, such as using bio-waste derived feedstocks [17] or earth-abundant catalysts [15].

The implementation of continuous flow protocols for paracetamol synthesis, particularly within a modular radial synthesis framework, presents a transformative strategy for mitigating drug shortages. The demonstrated protocols achieve high purity (≥98%) and excellent conversion (97-100%) with significantly reduced reaction times compared to traditional batch processes. This approach aligns with the broader trends of digitalization and automation in drug discovery and manufacturing, which are crucial for accelerating synthesis and enhancing supply chain robustness [18].

By adopting these on-demand synthesis strategies, the pharmaceutical industry can evolve towards a more agile, resilient, and sustainable manufacturing paradigm, ensuring the reliable availability of essential medicines like paracetamol.

The synthesis of complex organic molecules, particularly in the context of pharmaceutical development, increasingly relies on advanced automated techniques to improve efficiency, yield, and flexibility. Traditional linear synthetic approaches, while effective, often lack the adaptability required for rapid library synthesis and route optimization. This case study explores the multi-step convergent synthesis of Lidocaine—a prototypical local anesthetic agent—framed within the broader thesis that radial synthesis systems present a transformative platform for generating organic molecule libraries. We demonstrate how the principles of convergent synthesis and radial automation can be applied to a classic pharmaceutical compound, providing detailed protocols, quantitative data, and workflows directly applicable to research scientists and drug development professionals.

Convergent Synthesis and Radial Systems

The Paradigm Shift from Linear to Convergent Synthesis

In synthetic chemistry, a convergent synthesis is one where key intermediates are synthesized independently and then combined to form the final target molecule. This approach contrasts with linear synthesis, where reactions proceed in a sequential, step-by-step manner.

- Advantages of Convergent Synthesis: The primary advantage is higher overall yield for multi-step sequences. In a linear synthesis with 'n' steps, each with a yield of 'Y%', the overall yield is

Y^n. In a convergent approach, the longest linear sequence is shorter, leading to a higher overall yield [7]. Furthermore, it allows for the independent optimization of each branch of the synthesis before their union. - Relevance to Library Synthesis: When developing libraries of related molecules, a convergent strategy often employs a common advanced intermediate. This intermediate can be functionalized in the final steps to generate a diverse array of final compounds, significantly accelerating the exploration of structure-activity relationships (SAR) [19]. Analysis of industrial Electronic Laboratory Notebooks (ELN) indicates that over 70% of all reactions are involved in convergent synthesis, covering over 80% of all projects, underscoring its critical role in modern medicinal chemistry [19].

Radial Synthesis Systems as an Enabling Technology

Traditional automated flow synthesis systems are typically arranged in a linear fashion, which can be inflexible when changing reaction parameters or sequences. A radial synthesis system overcomes these limitations.

- Architecture: This design features a Central Switching Station (CSS) surrounded by multiple satellite reactors and a reagent delivery system (RDS) [3] [7].

- Functionality: The CSS directs reagent streams to and from any of the reactors, allowing intermediates to be stored, recirculated, or redirected. A single reactor can be used multiple times under different conditions within one synthetic sequence, enabling complex, convergent pathways that are difficult to achieve in a linear flow setup [7].

- Benefits for Convergent Synthesis: This platform provides unparalleled flexibility. As demonstrated in the synthesis of the drug Rufinamide, a radial synthesizer could perform both linear and convergent routes, with the latter being "easier to optimize and provided a higher yield" [7]. The system's modularity and remote operability make it ideal for the standardized production of small molecule libraries [3].

Application Note: Convergent Synthesis of Lidocaine

Synthetic Strategy and Rationale

Lidocaine (2-(diethylamino)-N-(2,6-dimethylphenyl)acetamide) is a classic amide-type local anesthetic. A convergent synthetic route to Lidocaine involves the separate preparation of the two main carbon chain components followed by their final coupling.

- Route Design: The chosen convergent pathway involves two key intermediates:

- 2,6-Dimethylaniline: The aromatic amine precursor.

- 2-Chloro-N,N-diethylacetamide: The acyl chloride derivative of the diethylamino chain.

- Convergent Step: The final step involves the nucleophilic acyl substitution reaction between 2,6-dimethylaniline and 2-chloro-N,N-diethylacetamide to form the amide bond, yielding Lidocaine. This approach allows for the independent synthesis and purification of each intermediate, and the final coupling step is a well-defined, high-yielding reaction.

Experimental Protocol

Synthesis of 2-Chloro-N,N-diethylacetamide

- Objective: To synthesize the acyl chloride component.

- Materials:

- Chloroacetyl chloride (1.0 equiv)

- Diethylamine (2.2 equiv)

- Dichloromethane (DCM), anhydrous

- Saturated aqueous sodium bicarbonate (NaHCO₃)

- Brine

- Anhydrous sodium sulfate (Naâ‚‚SOâ‚„)

- Procedure:

- Charge a round-bottom flask with a solution of diethylamine in anhydrous DCM and cool to 0°C in an ice-water bath.

- Slowly add chloroacetyl chloride dropwise via addition funnel, with vigorous stirring, maintaining the internal temperature below 5°C.

- After addition is complete, remove the ice bath and allow the reaction mixture to stir at room temperature for 2 hours (monitor by TLC).

- Transfer the reaction mixture to a separatory funnel and wash sequentially with 1M HCl, saturated NaHCO₃ solution, and brine.

- Dry the organic layer over anhydrous Naâ‚‚SOâ‚„, filter, and concentrate under reduced pressure to obtain 2-chloro-N,N-diethylacetamide as a colorless to pale yellow oil. The product can be used in the next step without further purification.

Convergent Coupling to Form Lidocaine

- Objective: To couple the two intermediates to form the final Lidocaine product.

- Materials:

- 2-Chloro-N,N-diethylacetamide (1.0 equiv)

- 2,6-Dimethylaniline (1.1 equiv)

- Acetonitrile or Toluene

- Potassium iodide (KI, catalytic amount)

- Triethylamine (TEA, 1.5 equiv) or other non-nucleophilic base

- Procedure:

- Charge a round-bottom flask with 2,6-dimethylaniline, 2-chloro-N,N-diethylacetamide, and acetonitrile.

- Add a catalytic amount of potassium iodide and triethylamine.

- Reflux the reaction mixture with stirring for 6-12 hours (monitor reaction progress by TLC or LC-MS).

- After completion, cool the reaction mixture to room temperature and concentrate under reduced pressure to remove most of the solvent.

- Quench the residue with water and extract with ethyl acetate (3 x 50 mL).

- Combine the organic extracts, wash with brine, dry over Naâ‚‚SOâ‚„, filter, and concentrate.

- Purify the crude product by recrystallization from a suitable solvent (e.g., hexane/ethyl acetate) to obtain pure Lidocaine as a white crystalline solid.

Data Presentation and Analysis

Table 1: Quantitative Data for Lidocaine Synthesis Intermediates and API

| Compound | Molecular Weight (g/mol) | Theoretical Yield (g) | Isolated Yield (%) | Physical Form | Purity (HPLC, %) |

|---|---|---|---|---|---|

| 2-Chloro-N,N-diethylacetamide | 149.61 | - | 85-95 | Colorless Oil | >95 (by GC-MS) |

| Lidocaine (Crude) | 234.34 | - | 75-85 | Off-white Solid | ~90 |

| Lidocaine (Purified) | 234.34 | - | 70-80 | White Crystals | >99 |

Table 2: Thermal and Crystallization Properties of Lidocaine and Related Eutectic Mixtures [20]

| Material | Melting Point / Range (°C) | Onset of Degradation (°C) | Crystallization Peak (°C) | Crystallization at RT |

|---|---|---|---|---|

| Lidocaine | 68 [20] | 196.56 [20] | 31.86 [20] | Yes [20] |

| Lidocaine-Tetracaine EM | Depressed [20] | 146.01 [20] | Not Observed [20] | No [20] |

| Lidocaine-Camphor EM | Depressed [20] | 42.72 [20] | 18.81 [20] | Yes [20] |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials and Reagents for Lidocaine Synthesis and Analysis

| Item / Reagent | Function / Role in Synthesis | Key Notes & Handling |

|---|---|---|

| Chloroacetyl Chloride | Electrophilic reagent for synthesizing the chloroacetamide intermediate. | Highly corrosive and lachrymatory. Handle only in a fume hood with appropriate PPE. |

| Diethylamine | Nucleophile to form the diethylamide moiety. | Flammable and corrosive. Use in a well-ventilated area. |

| 2,6-Dimethylaniline | Aromatic amine coupling partner; becomes the anilide portion of Lidocaine. | Toxic if ingested or inhaled. |

| Potassium Iodide (KI) | Catalytic agent to facilitate the SN2 reaction in the final coupling step (Finkelstein reaction). | Enhances the reactivity of the chloroacetamide. |

| Triethylamine (TEA) | Non-nucleophilic base; scavenges HCl generated during the amide bond formation. | Flammable and hygroscopic. |

| Modulated Temperature DSC (MTDSC) | Analytical technique to characterize melting, crystallization, and glass transitions of APIs and mixtures [20]. | Used in 3-cycle mode (heat-cool-heat) to study complex thermal events. |

| Raman Microspectroscopy | Provides vibrational information on chemical bonds; used to confirm molecular structure and interactions in eutectic mixtures [20]. | Non-destructive technique; can detect peak shifts indicating molecular interactions. |

| Pfi-4 | Pfi-4, MF:C21H24N4O3, MW:380.4 g/mol | Chemical Reagent |

| ADTL-EI1712 | ADTL-EI1712, MF:C22H18Cl2N4O2S2, MW:505.4 g/mol | Chemical Reagent |

Workflow Visualization: Radial Synthesis of a Lidocaine-Inspired Library

The following diagram illustrates how a radial synthesis system could be employed to create a library of Lidocaine analogs using a convergent approach and a common intermediate.