UPLC-MS vs. NMR in Automated Workflows: A Strategic Guide to Validation, Integration, and Application

This article provides a comprehensive comparison of Ultra-Performance Liquid Chromatography-Mass Spectrometry (UPLC-MS) and Nuclear Magnetic Resonance (NMR) spectroscopy within the context of modern, automated laboratories.

UPLC-MS vs. NMR in Automated Workflows: A Strategic Guide to Validation, Integration, and Application

Abstract

This article provides a comprehensive comparison of Ultra-Performance Liquid Chromatography-Mass Spectrometry (UPLC-MS) and Nuclear Magnetic Resonance (NMR) spectroscopy within the context of modern, automated laboratories. Tailored for researchers, scientists, and drug development professionals, it explores the foundational principles of both techniques and their synergistic integration into high-throughput workflows. We delve into methodological applications across diverse fields, from pharmaceutical impurity testing to natural product discovery, and address key challenges in troubleshooting and optimization. A core focus is placed on rigorous validation frameworks and comparative analysis, offering a strategic guide for selecting and validating the appropriate analytical technique to ensure data integrity, accelerate R&D cycles, and uphold regulatory compliance.

Core Principles: Demystifying UPLC-MS and NMR for Modern Automation

In the pursuit of scientific discovery and rigorous quality control within pharmaceutical and biochemical research, the selection and validation of analytical techniques are paramount. Ultra-Performance Liquid Chromatography-Mass Spectrometry (UPLC-MS) and Nuclear Magnetic Resonance (NMR) spectroscopy represent two foundational pillars of modern analytical science. While often viewed as competing platforms, they offer complementary strengths that, when understood and applied appropriately, can significantly accelerate research and ensure reliability. This guide objectively compares the technological principles, performance characteristics, and practical applications of UPLC-MS and NMR, framing the discussion within the critical context of analytical method validation and the rising paradigm of automated, data-driven research [1] [2].

Core Technological Principles and Workflow

UPLC-MS and NMR operate on fundamentally different physical principles, which directly dictate their applications, strengths, and limitations.

UPLC-MS is a hyphenated technique that combines a high-resolution separation dimension with a highly sensitive detection method. First, the sample mixture is introduced into a UPLC system, where components are separated based on their differential partitioning between a high-pressure liquid mobile phase and a stationary phase within a column [3]. The separated analytes are then ionized (commonly via electrospray ionization) and introduced into a mass spectrometer. Here, ions are separated according to their mass-to-charge ratio (m/z) and detected, providing information on molecular weight and, through fragmentation patterns (MS/MS), structural clues [4]. The entire process is inherently destructive to the sample.

NMR Spectroscopy, in contrast, is a non-destructive technique that probes the magnetic properties of atomic nuclei (most commonly ^1H or ^13C) within a powerful, static magnetic field [5] [4]. When exposed to radiofrequency pulses, these nuclei absorb and re-emit energy at frequencies highly sensitive to their local chemical environment (the "chemical shift"). The resulting spectrum provides a detailed fingerprint that conveys rich structural information, including atomic connectivity, molecular conformation, and dynamics, without the need for prior chromatographic separation [6] [4].

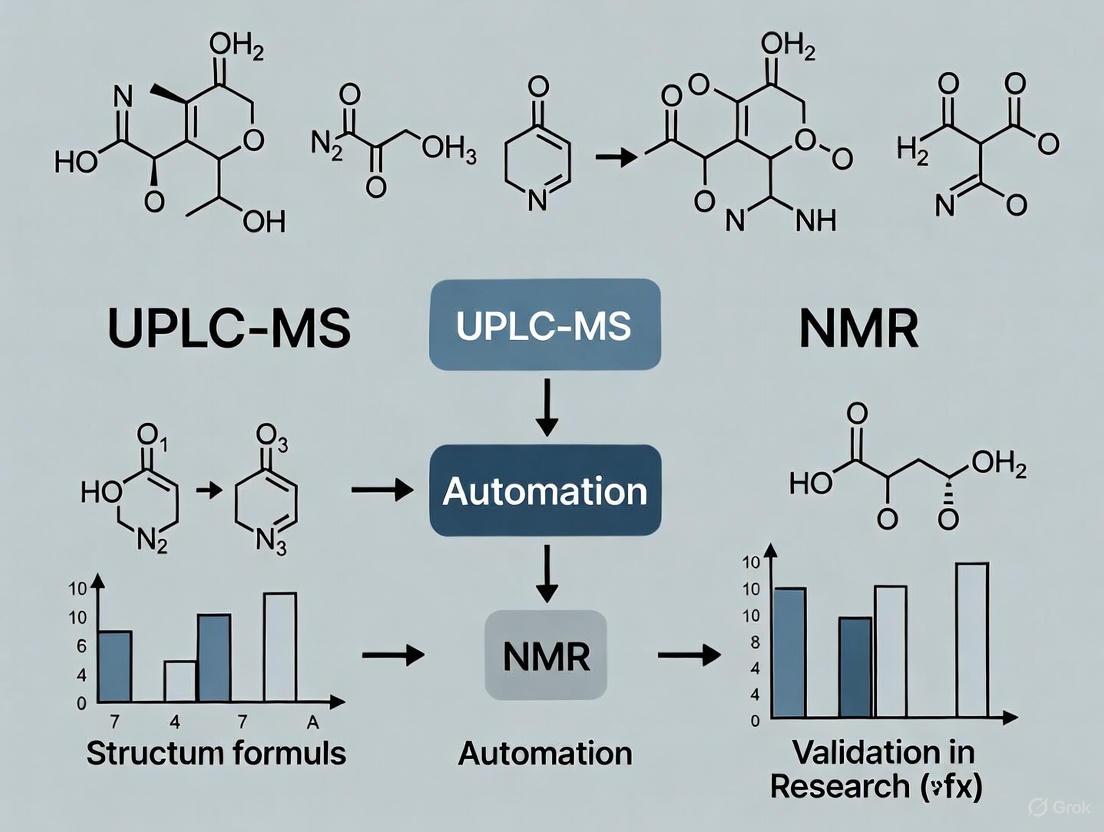

The following diagram illustrates the fundamental workflow and logical relationship between these two analytical approaches:

Diagram 1: Core Analytical Workflows of UPLC-MS and NMR.

Performance Comparison: Quantitative Data

The choice between UPLC-MS and NMR is often driven by specific performance requirements for a given application, such as metabolomics, natural product discovery, or pharmaceutical quality control. The table below synthesizes key comparative metrics from the literature [3] [4] [7].

Table 1: Comparative Performance Characteristics of UPLC-MS and NMR

| Performance Metric | UPLC-MS | NMR | Experimental Context & Citation |

|---|---|---|---|

| Sensitivity | Very High (femtomole to picomole range) [4]. Limits of Detection (LOD) can be 100-1000x lower than NMR. | Low to Moderate (nanomole to micromole range) [4] [7]. Requires significantly more analyte. | General comparison of instrumental capabilities for small molecule analysis [4] [7]. |

| Analytical Reproducibility | Average. Can be affected by matrix effects, ion suppression, and instrument tuning [4] [7]. | Very High. Spectra are highly reproducible across instruments and laboratories, and the technique is inherently quantitative [4] [7]. | Cited as a key advantage of NMR for metabolic phenotyping and quantitative analysis (qNMR) [3] [7]. |

| Metabolite/Chemical Coverage | High. Can detect 300-1000+ metabolites, especially when using multiple chromatography methods (RP, HILIC) [7]. | Lower. Typically profiles 30-100 metabolites in a standard ^1H NMR experiment [7]. | Comparison in the context of untargeted metabolomic profiling of biofluids [7]. |

| Throughput (Run Time) | Longer per sample due to chromatography (minutes). High-throughput via direct infusion (DI-MS) in ~seconds, but with less specificity [3]. | Fast. A simple ^1H NMR spectrum can be acquired in 4-5 minutes per sample with no separation needed [3]. | Comparison of UPLC-HRMS (5 days for 132 samples) vs. DI-HRMS (9 hours) and NMR speed [3]. |

| Structural Elucidation Power | Provides molecular formula (via high-resolution MS) and fragment clues. Often requires standards for definitive ID [4]. | Excellent. Provides unambiguous structural information, distinguishes isomers, and elucidates atomic connectivity via 2D experiments [5] [4]. | Critical for unknown identification in natural products and metabolomics [6] [4]. |

| Quantitative Correlation (vs. Reference) | For 10 specific urinary metabolites, DI-nESI-HRMS showed strong correlation (Pearson’s r > 0.9) with UPLC-HRMS [3]. | qNMR results for marker alkaloids showed good agreement with validated UPLC-PDA quantification [6]. Used to validate MS-based quantification [3]. | Direct comparison of quantitative results from MS and NMR platforms on the same sample sets [3] [6]. |

| Sample Preparation | More complex. Often requires extraction, derivatization (for GC-MS), or careful dilution to manage matrix effects [7]. | Minimal. Often requires only buffering in Dâ‚‚O for biofluids, or simple extraction for tissues [6] [7]. Can analyze intact tissues [7]. | Key practical difference affecting workflow simplicity and potential for automation. |

Integration in Automated and Autonomous Research

The modern trend toward high-throughput experimentation (HTE) and autonomous laboratories underscores the need for robust, automatable analytical techniques [1] [2] [8]. Both UPLC-MS and NMR are being integrated into these advanced workflows, but their roles differ.

UPLC-MS is a central workhorse in automated platforms due to its sensitivity, compatibility with liquid handling robots, and fast data acquisition for screening. It is routinely used for reaction monitoring, compound purity assessment, and high-throughput metabolomics [1] [8]. Recent advancements feature AI-powered LC systems that autonomously optimize method parameters [1].

NMR, while historically less automated, is increasingly incorporated into closed-loop systems for definitive structural verification. Benchtop NMR spectrometers are key components in modular autonomous platforms, where mobile robots transport samples from synthesizers to UPLC-MS and NMR for orthogonal analysis [2]. The heuristic decision-making in such systems uses both MS and NMR data to assign reaction success, mimicking expert judgment [2].

The convergence of these techniques within an automated validation framework is powerful: UPLC-MS provides rapid, sensitive screening and quantification, while NMR offers definitive, reproducible structural confirmation and validation of quantitative results, as seen in method validation for GMP release testing [9].

Diagram 2: Integrated UPLC-MS/NMR in an Autonomous Lab Workflow.

Detailed Experimental Protocols

To illustrate practical implementation, below are summarized methodologies from key comparative studies.

Protocol 1: Comparative Metabolic Profiling of Human Urine (UPLC-HRMS vs. DI-nESI-HRMS) [3]

- Sample: 132 human urine aliquots from an epidemiological cohort.

- Sample Prep (DI-nESI-HRMS): 10 µL urine diluted 50-fold with water. An aliquot mixed with labeled internal standards in methanol (final water:methanol, 1:2).

- Sample Prep (UPLC-HRMS): Used low- and high-speed centrifugation details (truncated in source).

- Instrumentation:

- UPLC-HRMS: Reversed-phase UPLC coupled to a high-resolution Q-TOF mass spectrometer.

- DI-nESI-HRMS: TriVersa NanoMate system for direct infusion nanoelectrospray coupled to a Synapt G2-S HRMS.

- Data Acquisition: Full-scan HRMS data in both positive and negative ion modes.

- Quantification: Calibration curves using the method of standard additions in a pooled urine sample for both platforms. Quantitative data for 35 metabolites compared.

- Analysis: Multivariate analysis (e.g., PCA) on full-scan data for sex-based classification. Correlation (Pearson’s, Passing-Bablok) and agreement (Bland-Altman) assessed between methods.

Protocol 2: Chemotypic Variation Study Using ^1H-NMR and UPLC-MS [6]

- Sample: 145 methanol extracts of Sceletium tortuosum plants.

- ^1H-NMR Protocol:

- Preparation: Plant material extracted with methanol. Extract dissolved in deuterated methanol with a reference standard.

- Acquisition: Spectra acquired on a standard NMR spectrometer (e.g., 600 MHz). Standard 1D ^1H pulse sequence with water suppression.

- Analysis: Multivariate analysis (PCA) on processed spectral data. Quantitative NMR (qNMR) used for marker compounds (e.g., pinitol, alkaloids).

- UPLC-MS Protocol:

- Preparation: Acid/base extracts of 289 samples.

- Acquisition: Separation on a UPLC system with a C18 column, coupled to a mass spectrometer.

- Analysis: Hierarchical cluster analysis (HCA) and orthogonal projections to latent structures-discriminant analysis (OPLS-DA) on MS data. Quantification of mesembrine alkaloids via a validated UPLC-PDA method.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for UPLC-MS and NMR Experiments

| Item | Primary Function | Typical Use Context |

|---|---|---|

| Deuterated Solvents (e.g., D₂O, CD₃OD) | Provides an NMR-inert solvent to avoid overwhelming analyte signals with solvent proton peaks. Essential for locking and shimming the NMR signal [5] [4]. | Sample preparation for ^1H-NMR spectroscopy of biofluids, tissue extracts, or synthetic compounds [3] [6]. |

| Labeled Internal Standards (Isotope-Labeled, e.g., ¹³C, ²H) | Corrects for variability in sample preparation and ionization efficiency in MS. Used for absolute quantification via calibration curves [3]. | Added to all samples in quantitative MS-based metabolomics (e.g., urinary metabolite panel) [3]. |

| NMR Reference Standard (e.g., TMS, DSS) | Provides a precise chemical shift reference point (δ 0 ppm) for calibrating NMR spectra, ensuring reproducibility and accurate quantification in qNMR [6]. | Added in a known concentration to sample solutions for ^1H-NMR analysis [6]. |

| LC-MS Grade Solvents (Acetonitrile, Methanol, Water) | Minimizes background chemical noise and ion suppression in the mass spectrometer. Essential for achieving high sensitivity and reproducible chromatography [3]. | Used as mobile phase components in UPLC-MS and for sample dilution/preparation [3]. |

| SPE (Solid-Phase Extraction) Cartridges | Purifies and concentrates analytes from complex biological matrices (e.g., urine, plasma), removing salts and proteins that can interfere with both MS and NMR analysis [4]. | Offline sample clean-up prior to LC-MS-NMR analysis, or in LC-MS-SPE-NMR workflows for trapping LC peaks for concentrated NMR analysis [4]. |

| Buffering Agents (e.g., Phosphate Buffer) | Controls pH in NMR samples, ensuring consistent chemical shifts for exchangeable protons (e.g., -NH, -OH) and improving spectral reproducibility [3] [6]. | Used in preparation of urine and other biofluid samples for NMR-based metabolomics [3]. |

| 15-Methylheptadecanoyl-CoA | 15-Methylheptadecanoyl-CoA, MF:C39H70N7O17P3S, MW:1034.0 g/mol | Chemical Reagent |

| AMP-PNP lithium hydrate | AMP-PNP lithium hydrate, MF:C10H17N6O12P3, MW:506.20 g/mol | Chemical Reagent |

In the field of modern analytical science, Ultra-Performance Liquid Chromatography-Mass Spectrometry (UPLC-MS) and Nuclear Magnetic Resonance (NMR) spectroscopy represent two foundational techniques for compound identification, quantification, and structural elucidation. The selection between these platforms involves critical trade-offs between sensitivity, throughput, structural insight, and quantitative accuracy. This guide provides an objective comparison of their performance characteristics, supported by experimental data and methodologies relevant to automated research environments, to inform scientists in research and drug development.

Fundamental Technical Comparison

UPLC-MS and NMR operate on fundamentally different physical principles, which directly define their inherent strengths and limitations for analytical applications. The core characteristics are systematically compared in the table below.

Table 1: Fundamental Comparison of UPLC-MS and NMR Technologies

| Characteristic | UPLC-MS | NMR |

|---|---|---|

| Detection Principle | Measurement of mass-to-charge ratio (m/z) of ionized molecules [4] | Excitation of magnetically-active nuclei (e.g., 1H, 13C) in a magnetic field [4] |

| Typical Limits of Detection | Femtomolar (10â»Â¹âµ) to attomolar (10â»Â¹â¸) range [10] | Micromolar (≥1 μM) range [10] |

| Quantitative Capability | Challenging; requires internal standards and is affected by ion suppression [10] [11] | Excellent; inherently quantitative with a wide dynamic range using a single internal standard [4] [11] |

| Throughput | High (minutes per sample with chromatography) [3] | Moderate to High (minutes for simple 1D experiments) [4] |

| Structural Information | Molecular mass, formula from exact mass, fragmentation patterns [4] | Direct information on atomic connectivity, functional groups, and stereochemistry [4] [10] |

| Key Strength | Extremely high sensitivity and specificity [10] | Non-destructive, provides definitive structural elucidation and is inherently quantitative [4] [10] |

| Key Limitation | Ion suppression from co-eluting compounds; cannot distinguish isomers without standards [4] [10] | Relatively low sensitivity compared to MS [4] |

Experimental Data and Performance Benchmarks

Quantitative Performance in Metabolomics

A direct comparison of quantitative performance was demonstrated in a study of human blood serum, where an NMR-guided MS quantitation method was developed. Using a single serum specimen quantified by NMR as a reference, researchers achieved absolute quantitation of 30 metabolites via MS. The results showed excellent correlation (R² > 0.99) for most metabolites, with a median coefficient of variation (CV) of 3.2%, validating that MS can achieve quantitative accuracy comparable to NMR when properly referenced [11].

Throughput and Classification Ability in Urinary Metabolite Profiling

A comparative study of UPLC-HRMS and Direct Infusion-nanoESI-HRMS for profiling 132 human urine samples provides critical throughput data. The study found that while UPLC-HRMS provided more specific metabolite identification, the total run time for the sample set in both polarities was 5 days for UPLC-HRMS versus only 9 hours for DI-nESI-HRMS. Despite the faster analysis, the DI-nESI method showed comparable classification ability for sex-related metabolic differences, with the significant discriminatory features being mostly the same in both platforms [3].

For quantitative analysis of a panel of 35 metabolites, 10 metabolites showed a strong correlation (Pearson’s r > 0.9) between the two MS platforms, while a further twenty showed acceptable correlation. Only five metabolites showed weak correlation (Pearson’s r < 0.4), overestimated by the DI-nESI method, highlighting that the suitability of faster, chromatography-free methods is analyte-dependent [3].

Structural Elucidation of Unknowns

The superior power of combining these techniques is exemplified in phytochemical research. An untargeted study of Crescentia cujete fruit combined UPLC-MS/MS-based molecular networking with conventional isolation and NMR. This integrated approach successfully identified 66 metabolites. Crucially, NMR was required for the definitive structural determination (Level 1 confirmation) of 18 compounds, including three previously undescribed iridoid glucosides. This demonstrates that while MS is powerful for profiling and tentative identification, NMR is often indispensable for confirming novel structures, especially for distinguishing isomers and establishing atomic connectivity [12].

Experimental Protocols for Comparison

Protocol for NMR-Guided MS Quantitation

This protocol enables absolute quantitation of metabolites in biological fluids using MS, with NMR as a reference [11]:

- Sample Preparation: Add methanol to serum samples in a 1:2 (v/v) ratio to precipitate proteins. Vortex, incubate at -20°C for 20 minutes, and centrifuge to pellet proteins.

- Sample Splitting: Filter the supernatant and split it into two parts.

- NMR Analysis: Reconstitute one part in a deuterated phosphate buffer containing the internal standard TSP (3-(trimethylsilyl)propionic acid-d4 sodium salt). Acquire 1H NMR spectra on a high-field spectrometer (e.g., 800 MHz) using a quantitative pulse sequence (e.g., CPMG with a long recycle delay). Use software to fit spectral lines and determine absolute metabolite concentrations with reference to TSP.

- MS Analysis: Dilute the other part for LC-MS/MS analysis. Use the NMR-derived concentrations from one specimen as a primary reference to generate a calibration for subsequent MS-based quantitation of other samples.

Protocol for Comparative UPLC-MS vs. Direct Infusion MS

This methodology directly compares chromatographic and infusion-based MS approaches [3]:

- Sample Preparation: Dilute urine samples (e.g., 10 μL diluted 50-fold with water). Add a multianalyte mixture of isotopically labeled internal standards.

- Platform Analysis:

- UPLC-HRMS: Inject samples onto a reversed-phase UPLC column coupled to a high-resolution mass spectrometer.

- DI-nESI-HRMS: Infuse samples directly into a nanoelectrospray source (e.g., TriVersa NanoMate) coupled to an HRMS instrument.

- Data Processing: For both platforms, perform exploratory analysis on full-scan HRMS data using multivariate statistics. For targeted quantification, use calibration curves prepared in a pooled urine matrix.

Integrated Workflows and Automation in Research

The complementary nature of UPLC-MS and NMR makes them ideal for integration in automated workflows. A key application is in process research, where automated systems like the FLEX AUTOPLANT combine benchtop NMR with other analytical techniques [13]. The workflow can be visualized as follows:

Diagram 1: Integrated Automated Analysis Workflow

Software solutions further enable this integration. For instance, scripts can automatically process and report data from both LC-MS and NMR analyses within a single document, performing tasks like peak picking for NMR and molecule matching for MS, thereby consolidating quality control [14].

Essential Research Reagents and Materials

Successful implementation of these analytical techniques relies on specific reagents and materials. The following table details key items used in the experiments cited in this guide.

Table 2: Key Research Reagents and Materials for UPLC-MS and NMR Analyses

| Reagent / Material | Function / Application | Experimental Context |

|---|---|---|

| Deuterated Solvents (e.g., Dâ‚‚O) | NMR solvent; provides a lock signal and minimizes strong solvent proton signals that would overwhelm analyte signals [4] [11]. | Used in serum metabolomics for sample preparation in deuterated phosphate buffer [11]. |

| Isotopically Labeled Internal Standards | MS internal standards; correct for variability in sample preparation and ionization efficiency for accurate quantification [3] [11]. | Used in both UPLC-MS and DI-nESI-MS analysis of urine and serum for targeted quantification of metabolites [3] [11]. |

| TSP (TMS-equivalent) | NMR internal standard; provides a reference peak at 0 ppm and enables absolute quantitation [11]. | Used as the concentration reference in quantitative NMR analysis of blood serum metabolites [11]. |

| Methanol (HPLC/MS Grade) | Protein precipitation; removes proteins from biofluibles prior to analysis to protect instrumentation and reduce matrix effects [3] [11]. | Used in a 1:2 serum-to-methanol ratio for protein removal in serum metabolomics [11]. |

| Ammonium Acetate / Acetic Acid | Mobile phase additives; promote ionization in LC-MS, particularly in positive and negative electrospray ionization modes [11]. | Used in the mobile phase for targeted LC-MS analysis of serum metabolites [11]. |

| Reverse-Phase UPLC Columns | Chromatographic separation; separates complex mixtures of analytes prior to MS detection to reduce ion suppression [3]. | Used in the UPLC-HRMS platform for profiling human urine samples [3]. |

UPLC-MS and NMR are not competing but profoundly complementary technologies. UPLC-MS offers superior sensitivity and is ideal for high-throughput profiling and targeted quantification of low-abundance metabolites, especially when leveraging fast, direct infusion methods. NMR provides unmatched capabilities in definitive structural elucidation and inherent quantitation, making it the gold standard for identifying novel compounds and validating quantitative methods. The future of analytical validation in automated research lies not in choosing one technique over the other, but in developing integrated workflows and data analysis platforms that seamlessly leverage the combined strengths of both UPLC-MS and NMR.

The landscape of drug discovery and metabolomics is undergoing a revolutionary transformation through the integration of Ultra-Performance Liquid Chromatography-Mass Spectrometry (UPLC-MS) and Nuclear Magnetic Resonance (NMR) spectroscopy into fully automated, high-throughput workflows. This convergence represents a paradigm shift from isolated analytical operations to connected ecosystems that accelerate research and development cycles. The combination of these complementary technologies provides researchers with a more comprehensive analytical toolkit: UPLC-MS brings exceptional sensitivity and selectivity for compound separation and identification, while NMR offers definitive structural elucidation and inherently quantitative data without the need for identical standards [4]. This guide objectively compares the performance of these integrated platforms against traditional standalone approaches, providing experimental data and methodologies that demonstrate their transformative potential in modern analytical laboratories.

The driving force behind this integration is the growing need to characterize complex mixtures of organic compounds synthesized at decreased scales in medicinal chemistry [15]. As the pharmaceutical industry shifts toward miniaturized parallel synthesis, the demand for purification and characterization platforms capable of handling thousands of compounds annually has intensified. The automated coupling of UPLC-MS and NMR addresses this challenge by providing complementary data critical for structural verification while significantly reducing manual intervention and accelerating the Design-Make-Test-Analyze (DMTA) cycles fundamental to drug discovery [16].

Technical Comparison: UPLC-MS and NMR as Complementary Analytical Pillars

UPLC-MS and NMR spectroscopy provide fundamentally different but highly complementary analytical information. Understanding their respective capabilities and limitations is essential for effective integration into automated workflows.

UPLC-MS operates on the principle of chromatographic separation followed by mass-based detection. It offers exceptional sensitivity with limits of detection in the femtomole range for analytes with high ionization efficiency, enabling the identification of compounds at very low concentrations [4]. The technique provides molecular weight information and, through exact mass measurements, enables the deduction of elemental composition. Tandem mass spectrometry (MS/MS) further yields structural information based on characteristic fragmentation patterns [4]. A key limitation, however, is that UPLC-MS typically requires authentic standards for definitive structural identification and can struggle to distinguish isobaric compounds and positional isomers.

NMR spectroscopy, in contrast, exploits the magnetic properties of certain atomic nuclei to provide definitive structural characterization. It identifies compounds through chemical shifts (influenced by electron shielding), splitting patterns (revealing neighboring nuclei), and multi-dimensional experiments (showing atomic connectivity) [4]. Unlike MS, NMR is not affected by matrix effects, is inherently quantitative, and provides non-destructive analysis with sample recovery potential [4]. However, NMR suffers from relatively low sensitivity, requiring microgram quantities of material and longer acquisition times ranging from minutes for simple 1H spectra to hours or days for more complex 2D experiments [4].

Table 1: Fundamental Characteristics of UPLC-MS and NMR Spectroscopy

| Parameter | UPLC-MS | NMR |

|---|---|---|

| Detection Limit | Femtomole range (10â»Â¹Â³ mol) [4] | Microgram range (10â»â¹ mol) [4] |

| Structural Information | Molecular weight, elemental composition, fragmentation patterns [4] | Atomic connectivity, functional groups, stereochemistry [4] |

| Quantitation | Requires standards; subject to matrix effects [4] | Inherently quantitative; no standards needed [4] |

| Sample Throughput | Seconds to minutes per sample [4] | Minutes to hours per sample [4] |

| Isomer Differentiation | Limited capability [4] | Excellent capability [4] |

| Sample Recovery | Destructive analysis [4] | Non-destructive; sample can be recovered [4] |

Integrated Workflow Architecture: From Sample to Analysis

The complete integration of UPLC-MS and NMR into automated platforms requires sophisticated engineering and software solutions that streamline the entire analytical process from sample preparation to data interpretation. This architectural framework enables seamless transition between analytical modalities while maintaining sample integrity and tracking.

Diagram 1: Automated UPLC-MS-NMR workflow

The integrated workflow begins with automated sample preparation using robotic systems like Chemspeed platforms, which handle weighing, dissolution, and dilution with precision and reproducibility [17]. These prepared samples then undergo UPLC-MS analysis where compounds are separated and initially characterized. Critical to the automation is the use of software platforms like SAPIO LIMS that track samples through the entire process and integrate with data processing tools such as Analytical Studio to interpret chromatographic and mass spectrometric data [16]. Based on this analysis, target compounds are directed to peak collection systems that concentrate analytes for NMR analysis. The automated NMR component then acquires spectral data, with recent innovations enabling sample generation with as little as 10 μg of material by utilizing dead volume in liquid handling systems [15]. Finally, data integration combines results from both techniques to provide comprehensive structural verification before compounds are delivered as DMSO solutions ready for biological assays [16].

Experimental Data and Performance Metrics

Metabolomics Studies Comparing Serum and Plasma Profiles

A comprehensive study comparing human serum and plasma metabolites using both untargeted ¹H NMR spectroscopy and UPLC-MS demonstrated the complementary nature of these techniques. After correcting for inter-individual variation, researchers identified distinct metabolic profiles between sample types [18].

Table 2: Metabolite Differences Between Serum and Plasma Identified by Combined NMR and UPLC-MS

| Analytical Technique | Higher in Serum | Lower in Serum |

|---|---|---|

| ¹H NMR | Lipoproteins, lipids in VLDL/LDL, lactate, glutamine, glucose [18] | - |

| UPLC-MS | Lysophosphatidylethanolamine (lysoPE)(18:0), Lysophosphatidic acid(20:0) [18] | Phosphatidylcholines (PC)(16:1/18:2, 20:3/18:0, O-20:0/22:4), lysoPC(16:0), PE(O-18:2/20:4), sphingomyelin(18:0/22:0), linoleic acid [18] |

The experimental protocol for this comparison involved collecting serum, platelet-rich plasma (PRP), platelet-poor plasma (PPP), and platelet-free plasma (PFP) from 8 non-fasting apparently healthy women. Samples were analyzed using untargeted standard 1D and CPMG ¹H NMR alongside reverse phase and hydrophilic (HILIC) UPLC-MS. Data analysis employed validated principal component and orthogonal partial least squares discriminant analysis, with special attention to correcting for inter-individual variation, which initially obscured sample-type differences [18].

Diagnostic Biomarker Discovery in Pregnancy Disorders

In a study screening serum potential biomarkers for intrahepatic cholestasis of pregnancy (ICP), researchers combined ¹H-NMR and UPLC-MS/MS to achieve comprehensive metabolic profiling. The experimental protocol first employed ¹H-NMR metabolomics on serum samples from 20 ICP patients and 20 matched healthy controls, revealing significant perturbations in amino acid metabolism and choline-related pathways [19]. UPLC-MS/MS was subsequently used to quantify eight choline pathway metabolites across expanded cohorts, including 40 ICP patients, 17 ursodeoxycholic acid (UDCA)-treated ICP patients, and 40 healthy pregnant women [19].

The integrated approach revealed marked elevations in serum choline (+92.0%), betaine (+22.0%), methionine (+37.7%), dimethylglycine (+163.1%), and cystathionine (+13.6%) in ICP patients compared to controls. UDCA intervention significantly reduced choline (-21.0%) and dimethylglycine (-32.5%) levels versus untreated ICP. Most importantly, the combination of choline and dimethylglycine demonstrated exceptional diagnostic performance with an area under the receiver operating characteristic curve (AUROC) of 0.88 when combined using a logistic regression model [19].

Natural Product Analysis Using Combined Platforms

Research on Panax ginseng berries from seven cultivars employed both UPLC-QTOF/MS and HR-MAS NMR-based metabolic profiling to characterize primary and secondary metabolites. The UPLC-QTOF/MS analysis focused on profiling 26 ginsenosides (secondary metabolites), while HR-MAS NMR was used to profile primary metabolites [20]. This combined approach enabled the classification of cultivars based on their metabolic characteristics. For example, the Kumpoong and Sunwon cultivars were classified based on ginsenoside profiles, while the Kumpoong and Gopoong cultivars were distinguished by their primary metabolites [20].

The experimental methodology revealed that the Gopoong cultivar contained higher levels of most amino acids (arginine, phenylalanine, isoleucine, threonine, and valine), the highest level of choline, and the lowest level of myo-inositol. The Kumpoong cultivar showed significantly lower levels of protopanaxatriol (PPT)-type ginsenosides Re and Rg2 compared to other cultivars, while other PPT-type ginsenosides were present in much higher amounts [20].

Automation Protocols and Implementation Frameworks

High-Throughput Purification and Characterization Workflow

Janssen R&D has implemented a comprehensive High-Throughput Purification (HTP) workflow that integrates RP-HPLC-MS and/or SFC-MS systems with NMR spectroscopy. This automated platform processes compounds at scales ranging from regular to microscale (∼3.0-75.0 μmol) and handles 36,000 compounds yearly [15] [16].

The experimental protocol begins with crude sample analysis via RP-LC-MS or SFC-MS systems. Method development employs selectivity as the primary parameter affecting resolution, achieved by using different stationary phases with varied surface chemistries and retentivities. For reversed-phase chromatography, different organic solvents and pH mobile-phase buffers modulate selectivity, while SFC incorporates additives into the organic content for the same purpose [16]. Following analysis, automated purification is performed, after which all purified compounds undergo High-Throughput Nuclear Magnetic Resonance (HT-NMR) analysis aided by in-house-built Python scripts to reduce cycle time [16]. The final output is registered compounds delivered as DMSO solutions ready for replication and distribution to biological assays.

Integrated Platform for Reaction Monitoring and Optimization

Bruker BioSpin and Chemspeed have developed integrated platforms that combine automated synthesis with real-time analysis. These systems feature Chemspeed's modular automation solutions coupled with Bruker's Fourier 80 benchtop NMR or high-field NMR instruments, creating closed-loop systems for reaction optimization [17].

The experimental setup involves Chemspeed systems carrying out reactions and feeding the resulting products directly into benchtop NMRs for real-time monitoring. Data transfer is facilitated by integrating Chemspeed's control software with Bruker's reaction monitoring software. When paired with advanced processing tools, data can be immediately interpreted and used to inform next steps. This creates a closed-loop system where AI or machine learning algorithms can direct the next round of experiments based on previous results, enabling fully autonomous, self-optimizing workflows [17].

Essential Research Reagents and Materials

Successful implementation of integrated UPLC-MS and NMR workflows requires specific reagents and materials optimized for compatibility across both analytical techniques.

Table 3: Essential Research Reagents for Integrated UPLC-MS-NMR Workflows

| Reagent/Material | Function/Purpose | Technical Considerations |

|---|---|---|

| Deuterated Solvents (e.g., Dâ‚‚O, deuterated acetonitrile) | NMR compatibility by reducing solvent proton interference [4] | Cost consideration; deuterium isotope effect may slightly shift retention times in LC [4] |

| LC-MS Grade Acetonitrile and Methanol | Mobile phase components for UPLC separation [21] [16] | High purity minimizes background noise and ion suppression in MS [16] |

| Ammonium Acetate/Formate | Mobile phase buffers for improved chromatographic separation [21] | Volatile salts compatible with MS detection; concentration typically 5-10 mM [21] |

| Formic Acid | Mobile phase additive to improve ionization in positive MS mode [21] [16] | Typical concentration 0.1%; can affect pH-dependent separation [21] |

| Ammonium Hydroxide | Mobile phase additive for basic pH conditions in MS [16] | Alternative to formic acid for negative ionization mode or basic compounds [16] |

| DMSO-d₆ | Deuterated solvent for NMR sample preparation [16] | Preferred for final compound dissolution for biological testing [16] |

Technique Comparison and Orthogonal Verification

The complementary strengths of UPLC-MS and NMR create a powerful orthogonal verification system that surpasses either technique alone. This is particularly valuable in applications requiring high confidence in structural identification, such as pharmaceutical development and natural product discovery.

UPLC-MS excels at detecting and quantifying compounds at low concentrations within complex mixtures, while NMR provides definitive structural confirmation, especially for isomers and novel compounds. This orthogonal relationship was demonstrated in a metabolomics study of second-trimester amniotic fluid and maternal urine, where UPLC-MS and NMR were used in tandem to identify pregnancy disorder biomarkers [22]. The combination reinforced a metabolic picture of fetal hypoxia, enhanced gluconeogenesis, TCA activity, and hindered kidney development affecting fetal malformation pregnancies, while also newly revealing changes in carnitine, pyroglutamate, and polyols [22].

In pharmaceutical settings, this orthogonal verification is crucial for quality control. A study on Menispermi Rhizoma established a UPLC-DAD-MS method for characterizing and quantifying alkaloids, successfully identifying a counterfeit sample that was further verified by appearance and microscopic identification [21]. The integrated method overcame limitations of previous quality control approaches, including scant chemical markers, long analytical times, consumption of large amounts of organic solvents, and limitations to single dosage forms [21].

Diagram 2: Orthogonal verification relationship between UPLC-MS and NMR

The integration of UPLC-MS and NMR into automated high-throughput workflows represents a significant advancement in analytical science, particularly for drug discovery and metabolomics. The experimental data and protocols presented demonstrate that these combined platforms offer synergistic capabilities that surpass what either technique can achieve independently. The continued evolution of these integrated systems—featuring enhanced automation, reduced material requirements, and sophisticated data processing—is poised to further accelerate research cycles while improving analytical confidence.

As labs continue their digital transformation, the seamless connection between synthesis, purification, and analytical verification will become increasingly standard. With ongoing innovations in miniaturization, sensitivity enhancement, and artificial intelligence-driven data interpretation, the fully automated lab integrating UPLC-MS and NMR technologies will become the benchmark for industrial and academic research, enabling faster discovery timelines and more reliable characterization of chemical entities.

Defining the Analytical Target Profile (ATP) for Technique Selection

In the realm of automated analytical research, selecting the right technology is a critical decision that directly impacts the quality, efficiency, and success of drug development projects. The Analytical Target Profile (ATP) serves as a foundational tool in this process, providing a prospective summary of the performance characteristics an analytical procedure must possess to be fit-for-purpose [23] [24]. This guide objectively compares two powerful techniques—UPLC-MS and NMR—within the context of ATP-driven selection, providing experimental data and protocols to inform scientists and development professionals.

Understanding the Analytical Target Profile (ATP)

The ATP is a formalized concept within regulatory guidelines such as ICH Q14 and USP <1220>. It defines the requirements for the reportable value produced by an analytical procedure, ensuring the method is suitable for its intended use throughout its lifecycle [23] [24].

- Key Definition: The ATP is a "prospective summary of the performance characteristics describing the intended purpose and the anticipated performance criteria of an analytical measurement" [23].

- Role in Technology Selection: The ATP drives the choice of analytical technology. It is defined based on the required quality of the measurement, independent of a specific technique, though the operating environment is a key consideration [23] [24]. A well-defined ATP enables scientists to screen and select the most appropriate technology from available fit-for-purpose options [25].

- Core Components: As illustrated in the example below, an ATP details the intended purpose, links to Critical Quality Attributes (CQAs), and defines performance characteristics and their acceptance criteria, such as accuracy, precision, and reportable range [24].

Table 1: Example Analytical Target Profile Structure

| Component | Description |

|---|---|

| Intended Purpose | Description of what the analytical procedure measures (e.g., quantitation of an active ingredient, impurity level) [24]. |

| Technology Selection & Rationale | The selected technology (e.g., HPLC, NMR) and justification based on the ATP requirements [24]. |

| Link to CQAs | Summary of how the procedure provides reliable results for the assessed quality attribute [24]. |

| Performance Characteristics | Criteria such as Accuracy, Precision, Specificity, and Reportable Range with defined acceptance limits [24]. |

Technique Comparison: UPLC-MS vs. NMR

Ultra-Performance Liquid Chromatography-Mass Spectrometry (UPLC-MS) and Nuclear Magnetic Resonance (NMR) spectroscopy offer complementary capabilities. The choice between them is guided by how well their inherent strengths align with the ATP's demands for a given application.

Table 2: Core Characteristics of UPLC-MS and NMR

| Characteristic | UPLC-MS | NMR |

|---|---|---|

| Sensitivity | Very High (femtomole range) [4] | Moderate (microgram range) [4] |

| Selectivity/Specificity | High (chromatographic separation + mass detection) [3] | High (resolves isobaric compounds and positional isomers) [4] |

| Structural Information | Molecular weight, fragmentation patterns; requires standards for definitive ID [4] | Direct atomic connectivity and functional group information [4] [26] |

| Quantification | Excellent with calibration; susceptible to matrix effects [4] | Inherently quantitative; no calibration curves needed [4] |

| Sample Throughput | High (minutes per sample) [3] | Low (minutes to hours per sample) [4] |

| Automation Friendliness | Highly amenable to automation [27] | Compatible with automated flow probes and liquid handling [28] [27] |

Experimental Data and Protocol Comparison

A direct comparison of UPLC-MS and Direct Infusion-nanoESI-MS (DI-nESI-MS) for human urinary metabolic profiling provides robust, quantitative data on performance. In this study, both methods were applied to the same set of 132 urine samples [3].

Key Experimental Outcomes:

- Throughput: DI-nESI-MS analysis was significantly faster, completing the sample set in 9 hours compared to 5 days for UPLC-MS in both polarities [3].

- Correlation of Quantitative Data: For a panel of 35 metabolites, 10 showed a strong correlation (Pearson’s r > 0.9) between the two MS methods, indicating these can be reliably measured by the faster, infusion-based technique. However, five metabolites showed weak correlation (r < 0.4) due to overestimation by DI-nESI-MS, highlighting a limitation where chromatographic separation is critical [3].

- Classification Ability: Despite the lack of separation, exploratory analysis of the full-scan HRMS data from DI-nESI showed comparable ability to UPLC-MS in classifying samples based on sex-related metabolic differences [3].

Detailed Experimental Protocol

The methodology below, adapted from the referenced study, outlines the key steps for a comparative metabolomics analysis [3].

1. Sample Preparation

- Material: Human urine samples (e.g., from an epidemiological cohort).

- Procedure:

- Thaw urine aliquots.

- Dilute sample (e.g., 10 µL urine) 50-fold with ultrapure water.

- Transfer an aliquot of the diluted sample to a well plate.

- Add a multianalyte mixture of isotopically labeled internal standards in methanol.

- Adjust to a final solvent proportion (e.g., water–methanol 1:2) [3].

2. Instrumental Analysis

- UPLC-HRMS Conditions:

- Column: Reversed-phase UPLC column (e.g., C18).

- Mass Spectrometer: High-Resolution Mass Spectrometer (e.g., Q-TOF).

- Gradient: Optimized binary solvent gradient for metabolite separation.

- Data Acquisition: Full-scan high-resolution mass spectrometry in both positive and negative ionization modes [3].

- DI-nESI-HRMS Conditions:

- Infusion System: Automated nanoelectrospray source (e.g., TriVersa NanoMate).

- Mass Spectrometer: High-Resolution Mass Spectrometer (e.g., Q-TOF).

- Data Acquisition: Direct infusion of the prepared sample with full-scan high-resolution mass spectrometry [3].

3. Data Processing and Analysis

- Metabolite Identification & Quantification: Use the ratio of analyte intensity to its corresponding internal standard. Generate calibration curves in a pooled sample matrix for quantification [3].

- Statistical Analysis: Perform multivariate analysis (e.g., PCA, PLS-DA) on the full-scan HRMS data for exploratory analysis. Use correlation analysis (e.g., Pearson’s) and regression models (e.g., Passing-Bablok) to compare quantitative results between platforms [3].

Integrated and Automated Workflows

Modern automation research increasingly focuses on integrating UPLC-MS and NMR into streamlined workflows to leverage their complementary strengths.

- The Case for Integration: MS excels at sensitive detection and quantification, while NMR provides definitive structural elucidation for unknowns and isomers [4] [26]. Integrating them provides a more comprehensive analytical picture.

- Automated Structure Verification: Systems like Sanofi's automated lab tool combine LC/MS and ¹H NMR data to efficiently verify chemical structures proposed by chemists, significantly speeding up the process [29].

- Workflow for Purification and Analysis: An automated purification-NMR workflow demonstrates high-throughput integration. This system purifies compounds via UPLC-MS and uses the "dead volume" from liquid handling to automatically prepare NMR samples in 1.7 mm tubes, enabling structural verification from as little as 10 µg of material without impacting biological assay samples [27].

Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for UPLC-MS and NMR Experiments

| Reagent/Material | Function | Application Notes |

|---|---|---|

| Isotopically Labeled Internal Standards | Enables precise quantification by correcting for matrix effects and instrument variability [3]. | Critical for both UPLC-MS and DI-nESI-MS quantitative assays. |

| Deuterated Solvents (e.g., D₂O, CD₃OD) | Provides a locking signal for the NMR spectrometer and minimizes solvent interference in the ¹H spectrum [4]. | Cost can be a consideration; D₂O is relatively inexpensive. |

| LC-MS Grade Solvents | High-purity solvents to minimize background noise and ion suppression in MS [3]. | Essential for achieving high sensitivity in UPLC-MS. |

| Boric Acid | Acts as a preservative for urine samples to maintain metabolite integrity during storage [3]. | Used in specific biofluid collection protocols. |

| Methanol & Water | Used for sample dilution, reconstitution, and as mobile phase components [3]. | Standard solvents for sample preparation in both techniques. |

UPLC-MS and NMR are not mutually exclusive technologies but are powerful partners in the automated analytical laboratory. The choice between them, or the decision to integrate them, must be driven by a clearly defined Analytical Target Profile. UPLC-MS is the champion for high-sensitivity, high-throughput quantification, whereas NMR is unparalleled for definitive structural elucidation and inherent quantification. By leveraging the ATP framework and adopting integrated, automated workflows, researchers can ensure their analytical strategies are rigorously designed, efficiently executed, and fully fit-for-purpose.

From Theory to Practice: Implementing Automated UPLC-MS and NMR Workflows

Automated Reaction Monitoring and Optimization with Online NMR

The integration of online Nuclear Magnetic Resonance (NMR) spectroscopy into automated reaction monitoring and optimization represents a significant advancement in process analytical technology. This approach provides real-time, non-destructive structural elucidation capabilities that are complementary to established techniques like Ultra-Performance Liquid Chromatography-Mass Spectrometry (UPLC-MS). As the pharmaceutical and chemical industries increasingly adopt high-throughput and parallel synthesis methodologies, the demand for robust, automated analytical techniques for structural verification and reaction optimization has intensified [27]. Online NMR fulfills this need by providing definitive structural information, including the ability to distinguish between isomers—a common limitation of MS-based techniques [4]. This article objectively compares the performance of automated online NMR against other analytical alternatives, particularly UPLC-MS, within the context of modern automation research, providing researchers and drug development professionals with experimental data and protocols to inform their analytical strategies.

Comparative Analysis of UPLC-MS and NMR in Automated Workflows

Fundamental Technical Comparison

Table 1: Fundamental Characteristics of UPLC-MS and NMR for Automated Analysis

| Characteristic | UPLC-MS | Online NMR |

|---|---|---|

| Primary Information | Molecular mass, elemental composition, fragmentation patterns [4] | Detailed structural information, atomic connectivity, isomer distinction [4] |

| Limit of Detection | Femtomole range (for high ionization efficiency) [4] | High nanogram to microgram range (∼10 μg for 1.7 mm tubes) [27] [4] |

| Quantitation | Semi-quantitative; susceptible to ion suppression/matrix effects [4] | Inherently quantitative; independent of matrix effects [4] |

| Isomer Differentiation | Limited capability [4] | Excellent for epimers, regioisomers, atropisomers [27] |

| Analysis Speed | Seconds per sample [4] | Minutes to hours per sample [4] |

| Sample Throughput | Very high (thousands/day possible) | Moderate to high (e.g., 36,000/year in one workflow) [27] |

| Automation Integration | Well-established in LC-MS workflows [27] | Emerging in high-throughput workflows [27] |

| Destructive Nature | Destructive | Non-destructive; sample recovery possible [4] |

Performance in Automated Reaction Monitoring and Optimization

Table 2: Performance Comparison in Automated Reaction Monitoring Applications

| Parameter | UPLC-MS | Online NMR |

|---|---|---|

| Structural Verification | Requires authentic standards for definitive identification [4] | Direct structure confirmation without standards [27] |

| Reaction Kinetics Monitoring | Excellent for fast kinetics due to rapid analysis [4] | Suitable for slower kinetics; real-time monitoring with flow systems [30] [31] |

| Isotope Detection | Can detect but may require specialized methods | Highly sensitive to isotopic variants, even without enrichment [32] |

| Reaction Optimization | Provides concentration data for key species | Enables direct structural insight for pathway optimization [30] |

| Solvent Requirements | Compatible with standard LC solvents | Prefers deuterated solvents to avoid signal interference [4] |

| Probe Technology | Standard ESI, APCI, etc. sources | Cryoprobes, microcoils, flow cells for enhanced sensitivity [4] |

Experimental Protocols and Implementation

High-Throughput Purification and NMR Workflow (Pfizer)

Pfizer developed an automated workflow that couples purification with NMR sample generation, handling 36,000 compounds annually. The process rescues the "dead volume" typically discarded during liquid handling to prepare NMR samples without consuming material prioritized for biological assays [27].

Protocol Details:

- Sample Submission: Compounds are submitted through a Laboratory Information Management System (LIMS) as singletons or libraries across three scales: Traditional (tPMC: 10–100 mg), Analytical (aPMC: >1–10 mg), and Micro (μPMC: 0.03–1 mg) [27].

- Purification: Uses Waters UPLC systems with 3.0 min gradients for μPMC/aPMC and 8.5 min for tPMC. Isolation is triggered by mass (ESI+) or UV. Both achiral (LC-MS) and chiral (SFC-MS) purifications are employed [27].

- NMR Sample Generation: Dynamic scripts control a Tecan liquid handler to add DMSO to vials containing the rescued dead volume (∼25 μL for traditional, ∼10 μL for analytical/micro scales). This creates samples suitable for 1.7 mm NMR tubes, obtaining quality spectra from as little as 10 μg of material [27].

- Analysis: Acquired NMR data undergoes automated structure verification, integrating synthesis, purification, and characterization into a single high-throughput workflow [27].

Self-Optimizing Flow Reactor with Online NMR

A system integrating a Magritek Spinsolve Ultra benchtop NMR with a flow reactor demonstrated fully automated reaction optimization using a Knoevenagel condensation model reaction [30].

Protocol Details:

- Reaction: Condensation of salicylic aldehyde and ethyl acetoacetate to form 3-acetyl coumarin, catalyzed by piperidine in ethyl acetate [30].

- Setup: An Ehrfeld microreactor system (MMRS) mixes reactant streams. The outflow is diluted with acetone/DCM and directed through the NMR flow cell [30].

- NMR Monitoring: The Spinsolve Ultra (80 MHz) operates in external control mode. A quantitative 1D EXTENDED+ protocol is used (4 scans, 6.55 s acquisition, 15 s repetition delay, 90° pulse). Measurements are triggered automatically until a steady state is reached (three consecutive stable readings) [30].

- Optimization Algorithm: A Bayesian algorithm in HiTec Zang's LabVision software adjusts the flow rates of the two reactant feeds (affecting both ratio and residence time) based on the NMR-measured yield. The system performed 30 iterations autonomously, achieving a maximum yield of 59.9% by balancing exploration of new conditions and exploitation of promising regions [30].

Calculation of Conversion and Yield:

- The aromatic proton integral (6.6-8.10 ppm, 4H) served as a constant reference (R).

- Aldehyde proton from salicylaldehyde (S1: 9.90-10.20 ppm).

- Olefinic proton from 3-acetyl coumarin (S2: 8.46-8.71 ppm).

- Conversion = (1 - S1/R) × 100%

- Yield = (S2/R) × 100% [30]

Automated Reaction Monitoring with Molecular Rotational Resonance (MRR)

As a comparative technique, an automated MRR spectroscopy system was developed for reaction monitoring, highlighting an alternative to NMR and MS [32].

Protocol Details:

- Interface: Uses a six-port valve with a 5 μL sample loop. A peristaltic pump circulates reaction mixture. Upon valve switching, the loop contents are dispensed into a heated inlet (up to 130°C) volatilized in neon carrier gas [32].

- Reactions Monitored:

- Imine formation between aniline and 4-fluorobenzaldehyde.

- Deuterium exchange in ethyl acetoacetate via keto-enol tautomerization in methanol-d4 [32].

- Analysis: The targeted IsoMRR spectrometer measures specific rotational transitions. The system provided kinetic data and determined reaction completion, demonstrating particular sensitivity for isotopic variants [32].

Workflow and System Diagrams

Automated MRR Reaction Monitoring Workflow

Self-Optimizing Flow Reactor with Online NMR

Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for Automated NMR Workflows

| Reagent/Material | Function/Application | Example from Research |

|---|---|---|

| Deuterated Solvents (e.g., D₂O, CD₃CN) | Reduces solvent proton interference in NMR spectra; used in mobile phase or for sample dilution [4]. | Used in LC-MS-NMR to minimize strong solvent signals that overwhelm analyte signals [4]. |

| 1.7 mm NMR Tubes | Enables analysis with limited material by reducing sample volume requirements. | Used in Pfizer's high-throughput workflow to obtain spectra from ~10 μg of material [27]. |

| NMR Flow Cells | Allows continuous real-time monitoring of reactions in flow chemistry systems. | Integrated with the Spinsolve Ultra and X-Pulse benchtop NMR systems for online reaction monitoring [30] [31]. |

| Automated Liquid Handlers (e.g., Tecan) | Precisely reformats samples, adds solvents, and rescues "dead volume" for NMR analysis. | Tecan systems used to prepare NMR samples from purification dead volume and reformat compounds into DMSO [27]. |

| Cryoprobes & Microcoils | Enhance NMR sensitivity, reducing the amount of compound required for analysis. | Microcoil probes with active volumes as low as 1.5 μL increase concentration and signal [4]. |

| Bayesian Optimization Software | Algorithmically determines the next set of reaction conditions to test based on analytical feedback. | HiTec Zang's LabVision software used to maximize yield in the Knoevenagel condensation [30]. |

Automated online NMR has established itself as a powerful technique for reaction monitoring and optimization, offering unique strengths in structural elucidation and isomer differentiation that complement the high sensitivity and speed of UPLC-MS. The experimental data and protocols presented demonstrate that the choice between these techniques is not a matter of superiority but of strategic application. UPLC-MS excels in high-speed, high-sensitivity quantitative analysis, while online NMR provides definitive structural verification and insight into reaction pathways, even distinguishing between isotopic labels and isomers. The integration of both techniques within automated workflows, as exemplified by Pfizer's high-throughput platform and the self-optimizing flow reactor, represents the future of analytical-driven research and development in pharmaceuticals and chemical synthesis. As benchtop NMR technology advances and automation solutions become more sophisticated, online NMR is poised to become as integral to high-throughput analysis as LC-MS is today [27].

High-Throughput Targeted Metabolomics using UPLC-TQ-MS/MS

Targeted metabolomics has emerged as a powerful quantitative approach for comprehensive assessment of metabolic phenotypes in biological systems, providing critical insights into physiological and pathological mechanisms [33]. Unlike untargeted methods that aim to broadly profile metabolites, targeted metabolomics focuses on precise quantification of specific metabolites with enhanced accuracy, reproducibility, and robustness—attributes essential for clinical research and drug development [33]. The integration of ultra-performance liquid chromatography (UPLC) with tandem quadrupole mass spectrometry (TQ-MS/MS) represents a technological advancement that enables high-throughput, sensitive, and selective analysis of hundreds of metabolites in complex biological matrices [34].

Within the framework of analytical technique validation, comparing orthogonal technologies is crucial for establishing comprehensive quality assurance protocols. While UPLC-TQ-MS/MS provides exceptional sensitivity and throughput for quantitative analysis, nuclear magnetic resonance (NMR) spectroscopy offers definitive structural characterization capabilities without destruction of the sample [4]. This comparison is particularly relevant in automated research environments where the complementarity of these techniques can be leveraged to enhance analytical rigor while maintaining efficiency.

Fundamentals of UPLC-TQ-MS/MS Technology

System Components and Principles

UPLC-TQ-MS/MS combines three complementary technologies that together enable high-performance metabolite analysis:

UPLC (Ultra-Performance Liquid Chromatography): Utilizes sub-2μm particles and high-pressure systems (typically >15,000 psi) to achieve superior chromatographic resolution, increased sensitivity, and reduced analysis times compared to conventional HPLC. The enhanced separation efficiency minimizes ion suppression in MS detection by reducing co-elution of analytes [33].

Tandem Quadrupole Mass Spectrometry: Employs two quadrupole mass analyzers separated by a collision cell. The first quadrupole (Q1) selects precursor ions of specific mass-to-charge (m/z) ratios, which are then fragmented in the collision cell. The second quadrupole (Q3) transmits specific product ions for detection. This configuration provides exceptional selectivity and sensitivity for targeted analysis [34].

Multiple Reaction Monitoring (MRM): The primary acquisition mode for targeted metabolomics, MRM monitors specific precursor-product ion transitions for each metabolite. This dual filtering approach significantly reduces background noise, enhances signal-to-noise ratios, and enables confident compound identification and quantification even in complex matrices [34] [33].

Experimental Design Considerations

Effective targeted metabolomics studies require careful experimental design to account for the dynamic nature of metabolomes, which are influenced by genetic, environmental, and physiological factors [33]. Key considerations include:

- Sample Population Selection: Appropriate control groups and minimization of confounding factors (medications, comorbidities)

- Study Design: Cross-sectional designs for diagnostic biomarker discovery versus longitudinal designs for therapeutic monitoring

- Sample Size: Adequate statistical power for detecting metabolomic differences

- Quality Control: Implementation of standardized protocols throughout the workflow [33]

Experimental Protocols for UPLC-TQ-MS/MS

Sample Preparation and Metabolite Extraction

Proper sample preparation is critical for reliable metabolomic data. The following protocol has been optimized for plant and mammalian tissue samples [34] [35]:

Table 1: Sample Preparation Steps for Targeted Metabolomics

| Step | Procedure | Key Considerations |

|---|---|---|

| Quenching | Flash-freezing in liquid N₂ or chilled methanol (-20°C to -80°C) | Performed immediately after collection to halt metabolic activity |

| Homogenization | Mechanical disruption in appropriate extraction solvent | Maintains temperature control to prevent metabolite degradation |

| Metabolite Extraction | Biphasic system: methanol/chloroform/water (typical ratios: 1:1:1 or 2:1:1) | Polar metabolites partition to methanol phase, lipids to chloroform phase |

| Protein Precipitation | Centrifugation at 14,000×g for 15 minutes at 4°C | Removes interfering proteins and particulates |

| Internal Standard Addition | Stable isotope-labeled analogs added prior to extraction | Corrects for variability in extraction and matrix effects |

For comprehensive metabolite coverage, the biphasic extraction system using methanol-chloroform-water is widely employed. Methanol effectively extracts polar metabolites while chloroform recovers non-polar compounds (lipids) [35]. The addition of internal standards before extraction is essential for accurate quantification, as it compensates for variations in extraction efficiency and matrix effects [35].

UPLC-TQ-MS/MS Analysis Parameters

The established analytical conditions for widely-targeted metabolomics are summarized below [34]:

Table 2: Typical UPLC-TQ-MS/MS Instrument Parameters

| Parameter | Configuration | Purpose |

|---|---|---|

| UPLC Column | C18 reversed-phase (1.7-1.8 μm particles) | High-resolution separation of metabolites |

| Mobile Phase | A: 0.1% formic acid in water; B: 0.1% formic acid in acetonitrile | Optimal ionization and chromatographic separation |

| Gradient | 3-20 minute linear or step gradients | Balance between throughput and resolution |

| Flow Rate | 0.3-0.4 mL/min | Compatible with MS interface requirements |

| Ionization Mode | ESI positive/negative switching | Broad metabolite coverage |

| MRM Transitions | Optimized for 500+ metabolites | Selective and sensitive quantification |

The MRM conditions must be experimentally optimized for each metabolite by flow injection analysis of authentic standards. This process determines the optimal precursor ion, product ion, and collision energy for maximum sensitivity and selectivity [34]. In a comprehensive method development study, researchers successfully optimized MRM conditions for 497 compounds from a library of 860 authentic standards, generating 61,920 spectra in the process [34].

Comparative Analytical Performance: UPLC-MS vs. NMR

Technical Capabilities and Limitations

UPLC-TQ-MS/MS and NMR provide complementary analytical capabilities with distinct strengths and limitations:

Table 3: Analytical Technique Comparison: UPLC-MS vs. NMR

| Parameter | UPLC-TQ-MS/MS | NMR |

|---|---|---|

| Sensitivity | Femtomole to picomole range [4] | Micromole range (typically 10-100 μg) [4] |

| Throughput | High (minutes per sample) [34] | Low (minutes to hours per 1D spectrum) [4] |

| Structural Information | Limited (molecular mass, fragmentation patterns) [4] | Comprehensive (atomic connectivity, stereochemistry) [4] |

| Quantitation | Relative and absolute with standards [33] | inherently quantitative without standards [4] |

| Sample Destruction | Destructive | Non-destructive [4] |

| Isomer Differentiation | Limited capability [4] | Excellent for positional isomers, stereoisomers [4] |

| Matrix Effects | Susceptible to ion suppression [4] | Minimal matrix interference [4] |

Method Validation Parameters

Comprehensive validation of UPLC-TQ-MS/MS methods should assess multiple performance characteristics:

Table 4: Validation Parameters for Targeted Metabolomics

| Validation Parameter | Acceptance Criteria | Experimental Approach |

|---|---|---|

| Linearity | R² ≥ 0.99 [21] | Calibration curves across expected concentration range |

| Precision | RSD ≤ 15% (intra-day and inter-day) [21] | Repeated analysis of QC samples |

| Accuracy | 85-115% recovery [21] | Spike-recovery experiments with authentic standards |

| Limit of Detection | Signal-to-noise ≥ 3:1 | Serial dilution of standards |

| Limit of Quantification | Signal-to-noise ≥ 10:1 with precision ≤20% RSD | Serial dilution of standards |

| Specificity | No interference from matrix components | Analysis of blank matrix samples |

Applications and Case Studies

Plant Metabolomics and Chemotyping

In a landmark study applying UPLC-TQ-MS/MS for comparative metabolomics, researchers analyzed 14 plant accessions from Brassicaceae, Gramineae, and Fabaceae families [34]. The methodology enabled quantification of approximately 100 metabolites in each sample, with hierarchical cluster analysis clearly distinguishing plant families based on metabolite accumulation patterns. Family-specific metabolites were identified using batch-learning self-organizing map analysis, demonstrating the utility of UPLC-TQ-MS/MS for chemotaxonomic classification and biomarker discovery [34].

Similarly, in cultivar discrimination of Artemisia argyi (Qiai), UPLC-MS-based metabolomics identified 12 chemical markers that distinguished four different cultivars [36]. Five of these markers were subsequently quantified using UPLC-TQ-MS/MS for more accurate content determination, highlighting the complementary nature of untargeted screening and targeted quantification approaches [36].

Clinical Biomarker Discovery

Targeted metabolomics has demonstrated significant utility in clinical research for identifying diagnostic and prognostic biomarkers. In a large-scale study analyzing serum from 1,448 individuals across six centers, researchers identified phenylalanyl-tryptophan and glycocholate as promising biomarkers for early detection of hepatocellular carcinoma [33]. Similarly, targeted analysis of 186 metabolites in plasma samples collected up to 14 years before diagnosis revealed 28 metabolites associated with liver cancer risk, implicating pathways in primary bile acid biosynthesis and phenylalanine, tyrosine, and tryptophan biosynthesis [33].

Integrated Workflows: Combining UPLC-MS and NMR

Automated Structure Verification

The pharmaceutical industry has developed integrated approaches that leverage the complementary strengths of UPLC-MS and NMR for automated structure verification. Sanofi partnered with ACD/Labs to develop an automated tool combining LC/MS and ¹H NMR to efficiently verify structures proposed by organic chemists [29]. This system collects, compiles, and evaluates analytical data automatically, sending results directly to the chemist, thereby streamlining the characterization process.

Similarly, Pfizer implemented an automated purification workflow coupled with MS and NMR that processes 36,000 compounds yearly [27]. This innovative approach generates 1.7 mm NMR samples from "dead volume" that is typically inaccessible during conventional liquid handling, obtaining quality NMR spectra from as little as 10 μg of material without consuming material prioritized for biological assays [27].

Hybrid Analytical Approaches

Several technological approaches have been developed to integrate LC-MS and NMR:

- Online LC-MS-NMR: Direct hyphenation for analysis of highly concentrated analytes (LODs ~10 μg) [4]

- Stop-flow LC-MS-NMR: Compromise approach where chromatographic flow is stopped to acquire NMR data [4]

- LC-MS-SPE-NMR: Solid-phase extraction for concentration and solvent exchange before NMR analysis [4]

- Loop collection: Intermediate storage of LC peaks for subsequent NMR analysis [4]

- Offline NMR: Complete separation of MS and NMR analyses with manual sample transfer [4]

The integration of these techniques is challenging due to differing solvent requirements, with NMR benefiting from deuterated solvents that are cost-prohibitive for routine LC mobile phases [4].

Essential Research Reagents and Materials

Table 5: Key Research Reagent Solutions for UPLC-TQ-MS/MS

| Reagent/Material | Function | Application Notes |

|---|---|---|

| Authentic Standards | Method development, quantification | Library of 500+ compounds recommended [34] |

| Stable Isotope-Labeled Internal Standards | Quantification normalization | Correct for matrix effects and recovery variations [35] |

| LC-MS Grade Solvents | Mobile phase preparation | Minimize background contamination and ion suppression |

| Methanol/Chloroform Extraction System | Metabolite extraction | Biphasic system for comprehensive metabolite recovery [35] |

| Formic Acid/Ammonium Acetate | Mobile phase additives | Enhance ionization and chromatographic separation [21] |

| Quality Control Pools | System monitoring | Quality assurance throughout analytical batches [33] |

Workflow Visualization

Targeted Metabolomics Workflow with NMR Validation

UPLC-TQ-MS/MS has established itself as a cornerstone technology for high-throughput targeted metabolomics, providing unparalleled sensitivity, selectivity, and quantitative capability for profiling hundreds of metabolites in complex biological samples. The technique enables robust comparative metabolomics studies with applications spanning plant chemotyping, clinical biomarker discovery, and drug development.

When positioned within the broader context of analytical technique validation, UPLC-TQ-MS/MS and NMR spectroscopy emerge as fundamentally complementary rather than competitive technologies. While UPLC-TQ-MS/MS excels at sensitive quantification of known metabolites in high-throughput workflows, NMR provides definitive structural characterization capabilities that are essential for identifying unknown compounds and validating structural assignments.

The ongoing development of integrated and automated workflows that combine these orthogonal techniques represents the future of comprehensive metabolomic analysis, particularly in regulated environments such as pharmaceutical development where both throughput and analytical rigor are paramount. As both technologies continue to advance—with improvements in MS sensitivity and NMR throughput—their synergistic application will further enhance our ability to comprehensively characterize complex metabolomes in biological and clinical research.

Combined LC/MS and NMR for Automated Structure Verification

The unambiguous verification of chemical structures is a critical step in drug discovery and development. Incorrectly characterized compounds can derail structure-activity relationship studies, waste resources, and jeopardize intellectual property [37]. While Ultra-Performance Liquid Chromatography-Mass Spectrometry (UPLC-MS) and Nuclear Magnetic Resonance (NMR) spectroscopy are foundational analytical techniques, each has intrinsic limitations when used in isolation. This guide compares their performance within the context of automated structure verification (ASV), arguing that a combined LC/MS and NMR approach is superior for ensuring analytical rigor and accelerating research workflows [4] [10].

Performance Comparison: UPLC-MS vs. NMR

The table below summarizes the complementary strengths and limitations of UPLC-MS and NMR spectroscopy, which form the basis for their synergistic integration in automated platforms.

Table 1: Comparative Analysis of UPLC-MS and NMR for Structure Verification

| Aspect | UPLC-MS | NMR | Implication for Combined ASV |

|---|---|---|---|

| Primary Strength | Exceptional sensitivity (femtomole range) [4]; High throughput. | Provides definitive structural and stereochemical information; Distinguishes isomers [4] [27]. | MS quickly identifies target peaks; NMR confirms identity and isomeric purity. |

| Key Limitation | Cannot reliably distinguish isobaric compounds or positional isomers [4] [27]. | Inherently low sensitivity (microgram level required) [4]; Longer acquisition times. | Automation focuses NMR on MS-identified peaks, optimizing use of instrument time and sample. |

| Quantitation | Can be challenged by ion suppression and matrix effects [4] [10]. | Inherently quantitative and immune to matrix effects [4]. | NMR provides a reliable quantitative check on MS-based purity assessments. |

| Sample Throughput in Automation | Very high (analysis in seconds) [4]. | Lower, but accelerated by automation (e.g., flow probes, automated sampling) [27]. | Workflow automation queues NMR analysis based on MS results, maximizing overall efficiency. |

| Data for Structure Verification | Molecular weight, formula (via exact mass), fragmentation patterns [4]. | Atomic connectivity, functional group environment, stereochemistry [4]. | Combined dataset provides a multi-parameter verification that is more robust than either technique alone. |

| Role in Automated Workflows | Ideal for initial screening, purity assessment, and triggering downstream NMR analysis [27]. | Essential for final confirmation of structure, especially for novel compounds or isomers [27] [38]. | Automated systems compile data from both techniques for a unified verification report [29]. |

Experimental Protocols for Automated Verification

The implementation of combined LC/MS-NMR ASV relies on standardized, high-throughput protocols. Below are detailed methodologies from key research.

Protocol 1: Integrated Purification and Microscale NMR Sample Generation

This protocol, developed for parallel medicinal chemistry, demonstrates a fully automated workflow from synthesis to structure verification [27].

- Compound Submission: Samples are submitted via a Laboratory Information Management System (LIMS) and categorized by scale: Traditional (10–100 mg), Analytical (>1–10 mg), or Micro (0.03–1 mg).

- UPLC-MS Purification & Analysis: An automated UPLC-MS system purifies compounds using mass- or UV-triggered fraction collection. Purity is assessed inline, and the concentration of the primary DMSO stock for biological assays is determined.

- NMR Sample Recovery from Dead Volume: Instead of discarding the inaccessible liquid handler dead volume (~10-25 µL), a Tecan liquid handler automatically dilutes it with deuterated solvent.

- Microcoil NMR Acquisition: The diluted sample is transferred to a 1.7 mm microcoil NMR tube. This probe's small active volume (1.5 µL) increases effective concentration, enabling quality ¹H NMR spectra from as little as 10 µg of compound [4] [27].

- Automated Data Processing & Verification: Spectra are automatically processed, analyzed, and compared to the predicted spectrum of the expected structure. Results are compiled and reported via the LIMS.

Protocol 2: Automated LC/MS and ¹H NMR Data Evaluation

This protocol outlines the software-driven verification process piloted by Sanofi and ACD/Labs [29] [38].

- Data Collection and Compilation: Upon synthesis, proposed structures and raw analytical data (LC/MS and ¹H NMR) are uploaded to a centralized system.

- Automated Processing and Prediction: Software automatically processes the spectra. For the proposed structure, it predicts the corresponding ¹H NMR spectrum and isotopic MS pattern.

- Consistency Evaluation: The system calculates match factors (e.g., NMR match factor, MS match factor) by comparing experimental data with predictions [38].

- Result Flagging and Reporting: Results are automatically evaluated. Compounds with consistent data are approved. Those with missing data or poor match factors are flagged for chemist review, with all relevant data compiled in a single report.

Workflow and Relationship Diagrams

Diagram 1: Automated Combined LC/MS-NMR Verification Workflow

Title: Automated workflow integrating purification, MS, NMR, and software verification.

Diagram 2: Complementary Role of MS and NMR in Verification

Title: Complementary data from MS and NMR converge for definitive verification.

The Scientist's Toolkit: Key Reagents & Solutions

Table 2: Essential Research Reagents and Materials for Combined ASV Workflows

| Item | Function in Workflow | Key Detail / Rationale |