Automated Multistep Synthesis of Small Molecules: Protocols, Platforms, and Future Directions for Accelerated Drug Discovery

This article comprehensively reviews the rapidly evolving field of automated multistep synthesis for small molecules, a transformative approach set to revolutionize pharmaceutical research and development.

Automated Multistep Synthesis of Small Molecules: Protocols, Platforms, and Future Directions for Accelerated Drug Discovery

Abstract

This article comprehensively reviews the rapidly evolving field of automated multistep synthesis for small molecules, a transformative approach set to revolutionize pharmaceutical research and development. We explore the foundational principles shifting small molecule production from manual craftsmanship to automated, standardized processes. The article provides a detailed analysis of major technological platforms—including iterative building block assembly, continuous-flow systems, radial synthesizers, and integrated self-optimizing systems—highlighting their unique capabilities, applications, and limitations. For researchers and drug development professionals, we offer practical insights into troubleshooting, optimization through real-time analytics, and AI-driven experimentation. Finally, we present rigorous validation through case studies of pharmaceutical synthesis and comparative analysis of platform performance, establishing automated synthesis as a critical enabler for faster, more reproducible, and democratized access to functional chemical matter.

The Foundations of Automated Synthesis: From Manual Craft to Industrial Revolution on the Molecular Scale

Application Notes: The Evolution of Automated Synthesis

The automation of chemical synthesis represents a paradigm shift in molecular discovery and development. This journey began with highly specialized instruments for biopolymers and is now expanding towards general platforms capable of assembling diverse small molecules. These advances are critical for accelerating drug discovery, where the synthesis bottleneck often limits the exploration of novel chemical space [1] [2].

1.1 The Foundation: Automated Peptide Synthesizers The commercialization of automated Solid-Phase Peptide Synthesis (SPPS) instruments in the late 20th century provided the first robust blueprint for molecular automation. These systems standardized the iterative cycle of deprotection, coupling, and washing on an insoluble resin support, transforming peptide synthesis from a labor-intensive art into a reproducible, scalable process [3]. The success of SPPS demonstrated key principles for automation: the use of a solid support to simplify purification, the application of universal coupling chemistries, and the power of programmable logic to control complex reaction sequences. Today, the automatic peptide synthesizer market, valued at approximately USD 650 million in 2023, is projected to grow to USD 1.2 billion by 2032, driven by demand for peptide therapeutics [4]. Modern systems range from benchtop units for research to floor-standing synthesizers for high-throughput production, integrating features like real-time monitoring and advanced fluidics [3] [5].

1.2 The Expansion to Oligonucleotides and the Modular Automation Paradigm Following peptides, the automation of DNA and RNA oligonucleotide synthesis using phosphoramidite chemistry on solid support became the next major success. This established a model for "modular automation," where specialized instruments are designed around a specific, highly optimized chemical framework. The parallel synthesis of multiple peptides or oligonucleotides in a single instrument run further increased throughput for library generation [5]. However, this approach, while powerful within its domain, is inherently limited to a narrow class of molecules defined by a standardized set of building blocks and reaction types.

1.3 The Grand Challenge: General Small Molecule Automation Extending automation to the vast and structurally diverse universe of small organic molecules presents a far greater challenge. Unlike peptides, small molecules lack a universal coupling chemistry and are synthesized via a wide array of reaction types and conditions. Two complementary philosophies have emerged to address this [2]:

- Customized Route Automation: This approach mirrors traditional organic synthesis, where a flexible, programmable machine (often employing continuous flow or advanced batch reactors) is configured to execute a specific multi-step synthesis route. This is exemplified by industrial efforts to automate the synthesis of specific drug candidates like prexasertib on kilogram scale [2].

- Generalized Platform Automation: This more ambitious approach seeks to create a "universal" machine that can synthesize many different targets using a common set of reactions and building blocks, akin to a molecular 3D printer. Progress here relies on innovations in retrosynthetic planning, robust and broad-scope reaction methodologies, and integrated robotic handling of solids and liquids.

1.4 The AI and Robotics Revolution The convergence of artificial intelligence (AI) and robotics is the primary accelerator for general small molecule automation. AI-driven platforms like DeepCure's "Inspired Chemistry" can design synthesis routes and control robotic platforms to execute multi-step sequences, as demonstrated by the automated synthesis of nirmatrelvir (Paxlovid) and 56 analogs [1]. Furthermore, Large Language Model (LLM)-based agent frameworks, such as the LLM-based Reaction Development Framework (LLM-RDF), are now capable of managing an end-to-end synthesis development cycle—from literature search and experimental design to hardware execution and spectral analysis—using natural language commands [6]. This integration is shifting the bottleneck from synthesis to imagination, enabling the rapid physical realization of AI-designed molecules [2] [7].

1.5 Quantitative Market and Performance Data The following tables summarize key quantitative data illustrating the growth and capabilities of automated synthesis technologies.

Table 1: Market Data for Automated Synthesis Platforms

| Metric | Automated Peptide Synthesizers (2023-2032) | Automated Parallel Peptide Synthesizers (2025-2033) | Context / Notes |

|---|---|---|---|

| Market Size (Base Year) | ~USD 650 Million (2023) [4] | >USD XXX Million (2025) [5] | Parallel synthesizers represent a high-throughput segment. |

| Projected Market Size | ~USD 1.2 Billion (2032) [4] | >USD XXX Million (2033) [5] | Strong growth driven by therapeutic demand. |

| CAGR | 7.3% [4] | ~10% (estimated) [5] | Indicates robust and sustained investment. |

| Dominant Segment | Pharmaceutical applications [4] | High-throughput synthesizers [5] | Driven by drug discovery needs. |

| High-Growth Region | Asia-Pacific [4] [5] | Asia-Pacific [5] | Expanding research infrastructure and biotech sectors. |

Table 2: Representative Experimental Performance Data from Automated Synthesis

| Platform / Technology | Target Molecule(s) | Key Performance Outcome | Reference / Context |

|---|---|---|---|

| DeepCure Inspired Chemistry | Nirmatrelvir (Paxlovid) & 56 analogs | Synthesized 30 mg of correct stereoisomer at 98% purity via 10-step automated synthesis. [1] | Proof-of-concept for complex small molecule automation. |

| Automated Flow Synthesis (Eli Lilly) | Prexasertib monolactate monohydrate | Produced 24 kg under cGMP with 75-85% yield and >99.7% HPLC purity. [2] | Demonstrates scalability and reliability for specific targets. |

| Automated Parallel SPPS | Peptide libraries | Capable of simultaneous synthesis of multiple peptides, dramatically increasing throughput for screening. [5] | Standard capability in modern peptide synthesizers. |

| LLM-RDF Guided Optimization | Copper/TEMPO alcohol oxidation | Automated end-to-end development including screening, kinetics, and optimization. [6] | Highlights AI's role in reaction development automation. |

Detailed Experimental Protocols

2.1 Protocol: Automated Solid-Phase Peptide Synthesis (SPPS) on a Benchtop Synthesizer This protocol outlines a standard Fmoc/t-Bu strategy-based synthesis on an automated peptide synthesizer [3] [4].

I. Research Reagent Solutions & Materials

| Item | Function | Typical Specification / Notes |

|---|---|---|

| Fmoc-AA-OH | Building blocks. | Fmoc-protected amino acids with side-chain protecting groups (e.g., t-Bu for Ser, Thr, Tyr; Boc for Lys, Trp; Pbf for Arg). |

| Rink Amide Resin | Solid support. | Provides a handle for cleavage to yield C-terminal amide peptides. Load: 0.1-0.8 mmol/g. |

| Activation Reagent | Activates carboxyl group. | HATU, HBTU, or DIC in combination with Oxyma Pure. |

| N,N-Diisopropylethylamine (DIPEA) | Base. | Neutralizes the hydrochloride salt of the amino acid and catalyzes coupling. |

| Dimethylformamide (DMF) | Primary solvent. | Peptide synthesis grade, low in amines. |

| Piperidine Solution | Deprotection reagent. | 20% (v/v) in DMF, removes the Fmoc group. |

| Cleavage Cocktail | Cleaves peptide from resin. | TFA-based (e.g., TFA/Water/Triisopropylsilane 95:2.5:2.5). |

| Diethyl Ether | Precipitation solvent. | For crude peptide precipitation post-cleavage. |

II. Methodology Step 1: Resin Swelling and Initial Deprotection.

- Load the prescribed amount of Rink amide resin into the synthesis vessel.

- Swell the resin with DMF (10-15 mL/g resin) for 30-60 minutes with agitation.

- Drain the DMF. Perform an initial Fmoc deprotection by treating the resin with 20% piperidine/DMF (2 x 5-10 minute treatments). Drain and wash the resin thoroughly with DMF (5-6 times).

Step 2: Automated Synthesis Cycle (Repeated for each amino acid). The instrument executes the following sequence for each coupling:

- Coupling: Deliver a solution of the incoming Fmoc-amino acid (4-5 eq.), activator (4-5 eq.), and DIPEA (8-10 eq.) in DMF to the vessel. Agitate for 30-60 minutes. Drain.

- Wash: Wash the resin with DMF 3-5 times to remove excess reagents.

- Deprotection: Treat the resin with 20% piperidine/DMF (1 x 3-5 min, 1 x 10-15 min) to remove the Fmoc group. Drain.

- Wash: Wash the resin with DMF 3-5 times. A Kaiser (ninhydrin) test can be performed after coupling to monitor completion.

Step 3: Final Deprotection and Cleavage.

- After the final amino acid is coupled, perform the final Fmoc deprotection (Step 2.3).

- Wash the resin sequentially with DMF, Methanol, and Dichloromethane (DCM), then dry under vacuum.

- Transfer the resin to a cleavage tube. Add ice-cold cleavage cocktail (10-15 mL/g resin). Agitate for 2-3 hours at room temperature.

- Filter the mixture to separate the resin. Precipitate the crude peptide by adding the TFA solution into cold diethyl ether. Centrifuge and collect the pellet.

- Purify the peptide via reversed-phase HPLC and characterize by LC-MS.

2.2 Protocol: AI-Driven, Automated Multi-Step Small Molecule Synthesis Platform This protocol describes a generalized workflow inspired by integrated AI-robotics platforms like DeepCure's Inspired Chemistry and LLM-RDF [1] [6].

I. Research Reagent Solutions & Materials

| Item | Function | Typical Specification / Notes |

|---|---|---|

| AI Synthesis Planner | Software for retrosynthesis & route design. | e.g., LLM-based agents (GPT-4, Claude) or specialized software (Chemputer OS). |

| Robotic Liquid Handler | Precise reagent dispensing. | Capable of handling solids and liquids, with inert atmosphere options. |

| Modular Reaction Stations | Vessels for varied conditions. | Blocks for heating, cooling, stirring, photochemistry, electrochemistry. |

| In-line Analysis Module | Real-time reaction monitoring. | HPLC, UPLC-MS, or ReactIR. |

| Automated Purification System | Post-reaction purification. | MS- or UV-triggered preparative HPLC or flash chromatography. |

| Chemical Inventory Database | Tracks building blocks/reagents. | Integrated with the planner for stock-aware synthesis planning. |

II. Methodology Step 1: Target Input and Retrosynthetic Planning.

- The researcher inputs the target molecule's SMILES string or name into the platform's software interface.

- An AI planning agent (e.g., an LLM fine-tuned on chemical literature) analyzes the target and proposes several potential retrosynthetic pathways [6].

- The planner evaluates routes based on predicted yield, step count, availability of starting materials in the onboard inventory, and safety. The user or a ranking algorithm selects the optimal route.

Step 2: Automated Execution of Multi-Step Sequence.

- The software translates the selected synthesis route into a machine-readable code (e.g., Python scripts) that controls the robotic platform.

- Reaction Setup: A hardware executor agent directs the robotic arm to retrieve specified starting materials and solvents from storage decks and dispense them into a designated reaction vial in the modular station [6].

- Reaction Execution: The station controls the reaction parameters (temperature, stirring, irradiation, etc.) for the prescribed time. An in-line analysis module may sample the reaction mixture at intervals to monitor conversion.

- Work-up and Transfer: Upon completion (determined by time or real-time analysis), the system executes a programmed work-up (e.g., liquid-liquid extraction using a separation robot, filtration, solvent evaporation).

- The intermediate is either purified automatically or transferred directly to the next reaction vessel. The cycle repeats for each step.

Step 3: Final Purification, Analysis, and Data Logging.

- The crude final product is directed to an automated purification system (e.g., preparative HPLC). Fractions are collected based on MS/UV signals.

- Purified fractions are analyzed by LC-MS and NMR for identity and purity verification.

- All steps, parameters, analytical data, and outcomes are automatically recorded in a digital lab notebook (LIMS), creating a reproducible and auditable record.

Visualization of Concepts and Workflows

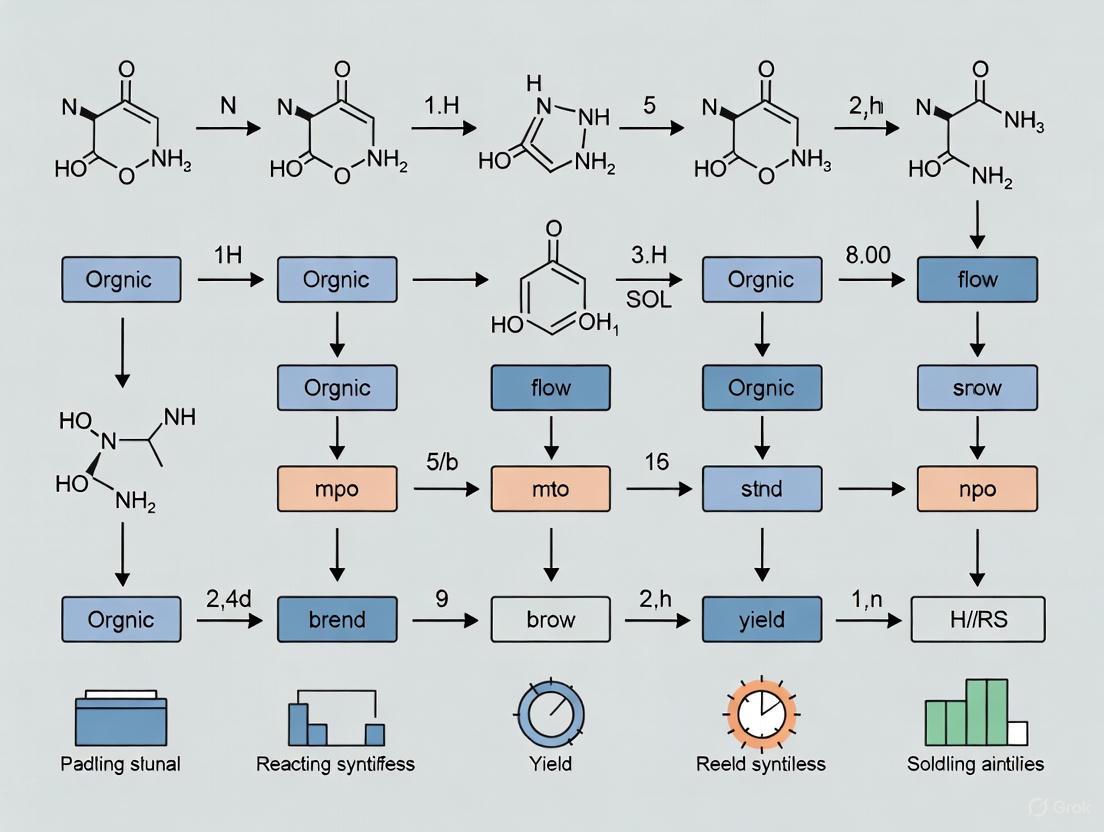

Diagram 1: Historical Evolution of Synthesis Automation

Diagram 2: Automated SPPS Cyclic Workflow

Diagram 3: AI-Robotic Platform for End-to-End Synthesis

The advancement of small molecule research is increasingly dependent on automated synthesis technologies. Two distinct paradigms have emerged: highly customized synthesis machines, designed for specific, complex synthetic challenges, and flexible general-purpose platforms that leverage automation and artificial intelligence for a wide range of applications. Customized machines offer tailored solutions for particular reactions or compound classes, often providing optimized conditions and high throughput for their narrow scope. In contrast, general-purpose platforms emphasize versatility, adaptability, and autonomous operation across diverse chemical spaces, from enzyme engineering to small molecule synthesis [8]. This article explores the core principles, applications, and experimental protocols for both paradigms within the context of automated multistep synthesis for drug development and research.

The choice between these paradigms is not merely technical but strategic, impacting research velocity, resource allocation, and scalability. Customized systems often deliver superior performance for targeted applications, while general-purpose platforms accelerate discovery by efficiently navigating vast experimental landscapes with minimal human intervention. The emergence of integrated systems combining AI-guided design with robotic execution, as seen in autonomous enzyme engineering platforms, marks a significant shift toward more intelligent and generalized synthesis strategies [8].

Comparative Analysis: Customized vs. General-Purpose Platforms

The table below summarizes the key quantitative and qualitative differences between these two core paradigms, helping researchers select the appropriate platform for their specific project goals.

Table 1: Strategic Comparison of Synthesis Platforms

| Feature | Customized Synthesis Machines | General-Purpose Platforms |

|---|---|---|

| Core Philosophy | Specialized, task-oriented automation for specific synthetic pathways or compound classes [9]. | Versatile, autonomous systems applicable to a wide array of chemical problems [8]. |

| Primary Application | Production of tailored chemical compounds, intermediates, or APIs where standard equipment is insufficient [10] [11]. | Broad-scope experimentation, including protein engineering, metabolic pathway optimization, and small molecule discovery [8]. |

| Development Focus | Optimizing for a single, high-value outcome (e.g., yield, purity for a specific molecule) [10]. | Maximizing generalizability and the efficiency of navigating large, multi-dimensional experimental spaces [8]. |

| Typical Throughput | Can be very high for the intended narrow scope of reactions. | Highly scalable; can construct and characterize hundreds of variants in iterative rounds [8]. |

| Automation Integration | Often hard-coded for a specific workflow. | Deeply integrated with AI and machine learning for closed-loop, iterative Design-Build-Test-Learn (DBTL) cycles [8]. |

| Key Advantage | Precision and potentially superior performance for a dedicated task. | Adaptability and efficiency; eliminates the need for human intervention and deep domain expertise for routine design [8]. |

| Inherent Challenge | Lack of flexibility; high cost and complexity for each new application [10]. | Requires sophisticated AI models and robust robotic integration; can be complex to set up [8]. |

Experimental Protocols

The following protocols illustrate how these platforms are applied in modern research settings, from specialized small molecule synthesis to generalized autonomous enzyme engineering.

Protocol 1: Customized Synthesis of Specialty Chemicals

This protocol outlines a typical workflow for producing a novel small molecule using a customized synthesis approach, commonly employed in pharmaceutical and specialty chemical development [10] [11].

1. Requirements Analysis & Scoping:

- Input: Client provides target molecule specification, required quantity, and purity standards [10].

- Process: Collaborative meetings between the client and the synthesis team to discuss feasibility, timeline, and cost. The manufacturer assesses internal expertise and equipment capabilities [9].

2. Route Design & Feasibility Assessment:

- Process: Chemists design and computationally evaluate potential synthetic routes. The chosen route is optimized for the constraints of the custom equipment (e.g., flow reactor, specialized catalyst handling).

- Key Considerations: Cost of raw materials, safety of proposed reactions, and waste generation [11].

3. Small-Scale Prototyping & Optimization:

- Process: The synthetic route is tested on a small scale (e.g., mg to g) to identify optimal reaction parameters (temperature, pressure, catalyst loading, solvent) using the custom apparatus.

- Quality Control: Analytical methods (e.g., HPLC, NMR, GC-MS) are developed and validated to assess yield and purity at each step [10].

4. Scale-Up and Production:

- Process: The optimized protocol is scaled up to the required production volume within the custom machine. This stage involves rigorous process control to ensure consistency and quality.

- Documentation: Detailed batch records are maintained, capturing all critical process parameters [10].

5. Purification & Final QC:

- Process: The final product is purified (e.g., crystallization, chromatography) and analyzed against the pre-defined specifications.

- Output: The custom-synthesized compound, along with a certificate of analysis, is delivered to the client [10].

Protocol 2: General-Purpose AI-Driven Platform for Molecule Optimization

This protocol is adapted from a published generalized platform for autonomous enzyme engineering, demonstrating a closed-loop DBTL cycle applicable to small molecule optimization [8]. The workflow is highly automated and executed on an integrated biofoundry.

1. Design: AI-Guided Library Generation

- Input: A starting molecular structure (e.g., a protein sequence or small molecule SMILES string) and a quantifiable fitness function (e.g., catalytic activity, binding affinity) [8].

- Process: A machine learning model (e.g., a protein Large Language Model or a chemical variational autoencoder) and an epistasis model are used to generate a diverse, high-quality library of variant designs. This maximizes the potential of identifying improved mutants in the first cycle [8].

- Output: A list of several hundred candidate variants for experimental testing.

2. Build: Automated Molecular Construction

- Process:

- DNA/Molecule Assembly: A robotic platform (e.g., iBioFAB) performs automated mutagenesis PCR and DNA assembly. A high-fidelity assembly method is used to eliminate the need for intermediate sequencing, ensuring a continuous workflow [8].

- Transformation & Culture: Automated microbial transformation is conducted in 96-well plates, followed by robotic colony picking and inoculation into deep-well plates for protein expression or molecule production [8].

3. Test: High-Throughput Functional Assay

- Process: The platform executes automated steps for plasmid purification, protein expression, and cell lysis. A high-throughput, automation-friendly functional assay (e.g., a colorimetric enzyme activity assay) is then performed to quantify the fitness of each variant [8].

- Data Collection: Assay data is automatically collected and formatted for model training.

4. Learn: Model Retraining and Iteration

- Process: The experimental data from the "Test" phase is used to retrain a low-N machine learning model. This model learns the complex relationship between sequence/structure and the fitness function, improving its predictive power [8].

- Iteration: The retrained model proposes a new set of variants for the next DBTL cycle, focusing the search on the most promising regions of the chemical space. This autonomous loop typically runs for 3-5 rounds [8].

Figure 1: Autonomous DBTL Cycle for Molecule Optimization

The Scientist's Toolkit: Key Research Reagent Solutions

Successful execution of the protocols above relies on a suite of essential reagents and materials. The following table details key components for a generalized AI-driven platform, as such systems integrate tools from multiple disciplines [8].

Table 2: Essential Research Reagents and Materials for an Autonomous Synthesis Platform

| Item | Function / Description | Application in Protocol 2 |

|---|---|---|

| Protein LLM (e.g., ESM-2) | A large language model trained on protein sequences that predicts the likelihood of amino acids at specific positions, used to infer variant fitness and guide library design [8]. | Design Phase: Generates a diverse and high-quality initial library of protein sequences for testing. |

| Epistasis Model (e.g., EVmutation) | A statistical model that identifies co-evolved residues in proteins, providing insights into the constraints and interactions within a protein family [8]. | Design Phase: Complements the LLM by focusing on evolutionarily informed mutations, enhancing library quality. |

| Low-N Machine Learning Model | A machine learning model (e.g., based on Bayesian optimization) specifically designed to make accurate predictions from small datasets, which is crucial for early DBTL cycles [8]. | Learn Phase: Trained on experimental data to predict the fitness of unsynthesized variants, guiding subsequent library design. |

| High-Fidelity DNA Assembly Mix | A specialized enzyme mix for highly accurate and efficient assembly of DNA fragments, critical for error-free variant construction without mid-process sequencing [8]. | Build Phase: Used in the automated mutagenesis PCR and assembly step to construct plasmid libraries encoding the designed variants. |

| Automation-Friendly Assay Reagents | Chemical substrates for functional assays (e.g., chromogenic or fluorogenic substrates) that are compatible with robotic liquid handling and high-throughput plate readers [8]. | Test Phase: Enables the quantitative, high-throughput measurement of variant activity (e.g., enzyme kinetics) directly in microplates. |

Workflow Visualization of a Generalized Platform

The architecture of a generalized platform involves the tight integration of computational and physical components. The diagram below maps the logical flow of information and control between these elements.

Figure 2: Architecture of an AI-Powered Synthesis Platform

The dichotomy between customized synthesis machines and general-purpose platforms represents a fundamental strategic choice in modern research. Customized systems remain indispensable for solving specific, high-value synthetic problems where performance cannot be compromised. However, the future of discovery and optimization increasingly leans toward the adaptability and sheer efficiency of general-purpose, AI-powered platforms. These systems, capable of autonomous experimentation, are not only faster but can also navigate complexity beyond human capacity, as demonstrated by the rapid engineering of novel enzymes [8].

The most powerful research environments will likely be hybrid, leveraging the strengths of both paradigms. The integration of robust experimental hardware with sophisticated AI, as exemplified by the generalized platform for enzyme engineering, provides a scalable roadmap for the future of automated multistep synthesis in small molecule research and drug development.

Nature excels in constructing complex natural products (NPs) through efficient, modular biosynthetic pathways. These processes assemble a vast chemical universe from a limited set of simple building blocks, such as acetic acid, malonic acid, mevalonic acid, methylerythritol phosphate, cinnamic acid, shikimic acid, and amino acids [12]. This "Building Block Philosophy" is characterized by its modular, iterative, and convergent logic, providing a powerful blueprint for advancing automated multistep synthesis in small molecule research. For drug discovery professionals, emulating this logic is not merely an academic exercise; it is a strategic imperative for streamlining the synthesis of complex molecules, thereby accelerating the journey from AI-designed structures to testable compounds [1].

The central challenge in modern small molecule research lies in the synthesis bottleneck. While artificial intelligence can design increasingly complex structures, transforming these digital designs into physical molecules for testing remains a time-consuming and labor-intensive process, often requiring multi-step synthesis with extensive purification [13] [1]. This bottleneck critically limits the exploration of diverse chemical space around lead molecules. By adopting and automating Nature's biosynthetic logic—which meticulously plans the assembly of complex architectures from simpler, readily available precursors—researchers can overcome these limitations. This approach enables the rational assembly of complex molecular architectures with unprecedented efficiency and reproducibility, mirroring the processes that Nature has optimized over millennia [14] [12].

Computational Tools for Deconstructing and Planning Synthesis

BioNavi-NP: A Toolkit for Navigating Biosynthetic Pathways

The complete biosynthetic pathways remain unknown for most of the over 300,000 cataloged natural products, creating a significant barrier to their heterologous biosynthesis and engineering [12]. BioNavi-NP is a deep learning-driven toolkit designed to address this challenge by predicting plausible biosynthetic pathways for both natural and NP-like compounds. Its architecture and performance are summarized below.

Single-Step Prediction Model: At its core, BioNavi-NP employs transformer neural networks trained on both general organic reactions and specialized biosynthetic reactions. This model performs single-step bio-retrosynthesis predictions in an end-to-end manner, generating candidate precursors for a target molecule [12].

Multi-Step Pathway Planning: Building on the single-step model, BioNavi-NP uses an AND-OR tree-based planning algorithm to navigate iterative multi-step bio-retrosynthetic routes. This approach efficiently manages the combinatorial explosion of potential pathways, identifying optimal routes from simple building blocks to complex targets [12].

Table 1: Performance Evaluation of BioNavi-NP on a Test Set of 368 Compounds

| Metric | Performance | Comparison vs. Rule-Based |

|---|---|---|

| Pathway Identification Rate | 90.2% | Not Available |

| Reported Building Block Recovery | 72.8% | 1.7x more accurate |

| Single-Step Top-1 Accuracy | 21.7% (ensemble) | 1.1% absolute increase |

| Single-Step Top-10 Accuracy | 60.6% (ensemble) | 18.5% absolute increase |

The data in Table 1 demonstrates that BioNavi-NP significantly outperforms conventional rule-based approaches like RetropathRL [12]. The model's high accuracy is achieved through data augmentation and ensemble learning. Training on a combined dataset of biochemical reactions and natural product-like organic reactions (USPTO_NPL) considerably boosted performance, whereas training on organic reactions alone failed to predict biosynthetic steps accurately. This underscores that while biosynthetic and organic chemistry share common principles, they occupy distinct chemical spaces [12].

Neuro-Symbolic Programming for Retrosynthetic Planning

Inspired by human learning, a data-driven group retrosynthesis planning model employs a neuro-symbolic framework that evolves from practical experience [15]. This algorithm operates through three continuously alternating phases designed to mimic expert learning and strategy development:

- Wake Phase: The system attempts to solve retrosynthetic planning tasks, constructing an AND-OR search graph guided by neural network models. It records both successful synthesis routes and failures for subsequent analysis.

- Abstraction Phase: The system analyzes the recorded data to extract reusable, multi-step reaction strategies. It specifically identifies "cascade chains" (sequences of consecutive transformations) and "complementary chains" (interacting reactions where one serves as a precursor to another).

- Dreaming Phase: The model is refined using generated "fantasies" (simulated retrosynthesis experiences) and replayed experiences. This phase addresses the data-hungry nature of machine learning models and teaches the system how to better apply the abstract strategies discovered in the previous phase [15].

This neuro-symbolic approach proves particularly valuable for processing groups of structurally similar molecules, such as those generated by AI models. It discovers and leverages shared synthesis patterns and repeat pathways, leading to a progressive decrease in marginal inference time as the algorithm processes more molecules [15].

Automated Platforms for Executing Complex Syntheses

The Chemputer: A Universal Chemical Robotics Platform

The Chemputer represents a paradigm shift in chemical synthesis, enabling the standardized and autonomous execution of complex syntheses with minimal human intervention [13]. This platform has been successfully demonstrated in the synthesis of molecular machines, specifically [2]rotaxanes—structures of exceptional complexity for nanotechnology applications.

Key features of the Chemputer platform include:

- Integration of On-Line Spectroscopy: The system dynamically adjusts process conditions using real-time feedback from NMR and liquid chromatography. This allows for yield determination and ensures controlled reaction progression [13].

- Chemical Description Language (XDL): The platform uses XDL to achieve synthetic reproducibility, describing synthetic procedures in a standardized, machine-readable format that can be executed autonomously [13].

- Automated Purification: The system addresses a critical bottleneck in multi-step synthesis through multiple column chromatography techniques, including silica gel and size exclusion chromatography [13].

In practice, the Chemputer standardized and autonomously executed a divergent four-step synthesis and purification of molecular rotaxane architectures, averaging 800 base steps over 60 hours on an analytical scale. This level of automation not only enhances reliability and reproducibility but also frees researchers from repetitive manual experimentation, enabling more ambitious and exploratory work [13].

Mobile Robotics for Exploratory Synthesis

A modular autonomous platform using mobile robots demonstrates a revolutionary approach to general exploratory synthetic chemistry [16]. This system integrates free-roaming mobile robots that operate a Chemspeed ISynth synthesis platform, an ultrahigh-performance liquid chromatography–mass spectrometer (UPLC-MS), and a benchtop NMR spectrometer, creating a flexible and scalable laboratory workflow.

The platform's operation follows a synthesis–analysis–decision cycle that closely mimics human protocols:

- Synthesis: Reactions are performed in the automated synthesis platform.

- Analysis: The platform prepares aliquots of reaction mixtures for analysis. Mobile robots transport these samples to separate, unmodified UPLC-MS and NMR instruments.

- Decision: A heuristic decision-maker processes the orthogonal NMR and UPLC-MS data to autonomously select successful reactions for further study without human input [16].

This approach is particularly valuable for exploratory synthesis where outcomes are not defined by a single scalar metric (like yield). The system has been successfully applied to structural diversification chemistry, supramolecular host-guest chemistry, and photochemical synthesis, demonstrating its versatility [16].

Table 2: Comparison of Automated Synthesis Platforms

| Platform | Key Technology | Application Demonstrated | Key Metric |

|---|---|---|---|

| Chemputer [13] | On-line NMR & LC feedback | [2]Rotaxane synthesis | 800 steps over 60 hours |

| Mobile Robot Platform [16] | Free-roaming robots, modular analysis | Supramolecular self-assembly | Pass/Fail binary grading |

| DeepCure Inspired Chemistry [1] | AI with robotic instrumentation | Paxlovid & 56 analogs | 30 mg at 98% purity |

| onepot AI Platform [17] | AI agents, LLMs for literature review | Multi-step small molecule synthesis | 2.7B chemical space exploration |

Experimental Protocols

Protocol for Autonomous Multi-Step Synthesis Using the Chemputer Platform

This protocol describes the procedure for autonomous synthesis of [2]rotaxanes using the Chemputer platform, adaptable to other multi-step small molecule syntheses [13].

I. Preparation and System Setup

- Materials: All starting materials and reagents should be of synthesis grade. Prepare solvents appropriate for the reaction and subsequent purification steps (e.g., hexanes, ethyl acetate for chromatography).

- Equipment Setup: Ensure the Chemputer platform is correctly configured with all necessary fluidic modules, solid-phase extraction columns, and in-line analytical instruments (NMR flow cell, liquid chromatography). Verify the integrity of all connections.

- XDL Script Preparation: Code the synthetic procedure using the Chemical Description Language (XDL). The script should detail all steps, including reaction, workup, and purification parameters. For the referenced [2]rotaxane synthesis, the script averaged 800 base instructions [13].

II. Synthesis Execution and Real-Time Monitoring

- Reaction Initiation: Execute the XDL script. The platform will autonomously handle the dispensing of reagents and solvents to initiate the reaction under specified conditions (temperature, atmosphere).

- On-line Analysis: The system will periodically route reaction aliquots to the in-line NMR spectrometer for ^1^H NMR analysis and to the liquid chromatograph. The real-time feedback from these analyses is used to dynamically adjust process conditions, such as reaction time or temperature [13].

- Reaction Quenching: Upon completion (as determined by on-line analysis), the platform will automatically quench the reaction as per the XDL script.

III. Automated Purification and Product Isolation

- Purification Method Selection: The system will prepare the crude product for purification. The XDL script specifies the purification method, which may include silica gel column chromatography or size exclusion chromatography [13].

- Fraction Collection: The platform collects eluent fractions based on chromatographic triggers (e.g., UV signal).

- Solvent Removal: The collected fractions containing the target product are automatically concentrated by the platform.

- Final Product Analysis: The isolated product is automatically analyzed by NMR and LC to confirm identity and purity. For the [2]rotaxane synthesis, this protocol achieved products on an analytical scale suitable for feasibility studies [13].

Protocol for Automated Reaction Development and Scale-Up (DeepCure Inspired Chemistry)

This protocol outlines the process for automated reaction development and synthesis of complex small molecules, as demonstrated by the synthesis of nirmatrelvir (Paxlovid) and its analogs [1].

I. Reaction Scouting and Condition Optimization

- Platform: DeepCure's Inspired Chemistry platform, incorporating off-the-shelf instruments and robots (liquid handlers, MS-triggered purification instruments, decappers, shakers).

- Reaction Selection: The platform currently supports approximately 28 different reaction types, with a goal to expand to 100 by the end of 2025 [1].

- Automated Reaction Development: The system executes a process to identify the optimal conditions (catalyst, solvent, temperature, concentration) for synthesizing the target molecules. The use of robots ensures consistent data generation for each reaction type [1].

II. Multi-Step Synthesis Execution

- Software Integration: The AI-based software designs the small molecules and generates synthetic routes. The software is tightly integrated with the robotic instruments to execute the synthesis.

- Step-wise Execution: The platform performs the synthesis iteratively. For nirmatrelvir, this involved 10 synthesis steps, including 5 purification steps [1].

- In-process Control: The platform performs necessary purifications and intermediate analyses to ensure the fidelity of each step.

III. Final Purification and Quality Control

- Purification: The final product is purified using MS-triggered purification instruments to achieve high purity.

- Output: The system delivers the target molecules at a specified scale. For the proof-of-concept, it produced 30 mg of the correct nirmatrelvir stereoisomer at 98% purity and 56 analogs at 1 mg scale [1].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Research Reagents and Materials for Automated Biosynthetic Studies

| Item | Function/Application | Example/Note |

|---|---|---|

| Acyl-CoA Extender Units | Building blocks for polyketide biosynthesis; incorporated by PKS assemblies. | Malonyl-CoA, Methylmalonyl-CoA; specialized units (e.g., Allylmalonyl-CoA) can be engineered [14]. |

| Non-proteinogenic Amino Acids | Building blocks for nonribosomal peptide synthesis; incorporated by NRPS. | D-amino acids, Ornithine; expand structural diversity of peptide natural products [14]. |

| Chassis Organism | Heterologous host for expressing engineered biosynthetic pathways. | Streptomyces avermitilis, E. coli, Aspergillus nidulans; chosen for genetic tractability and precursor supply [14]. |

| λ RED Recombinase System | Enables rapid genetic manipulation of biosynthetic gene clusters in host organisms. | Used for gene knock-outs, replacements, or insertions; facilitated synthesis of fluorosalinosporamide [14]. |

| Benchtop NMR Spectrometer | Provides real-time, in-line structural analysis for autonomous synthesis platforms. | 80-MHz instrument used in mobile robotic platform for autonomous decision-making [16]. |

| UPLC-MS System | Provides orthogonal analytical data (mass, purity) for autonomous synthesis platforms. | Integrated with robotic sample handling for high-throughput analysis [16]. |

| XDL (Chemical Description Language) | Standardizes and codifies synthetic procedures for autonomous execution. | Enables reproducibility and sharing of complex synthetic protocols [13]. |

Automated multistep synthesis represents a paradigm shift in small molecule research, moving chemical synthesis from a manual, artisanal process to a standardized, engineered one. This transformation is driven by three core pillars: enhanced reproducibility through precise digital control, improved operator safety by minimizing exposure to hazardous materials, and the democratization of molecular innovation by making complex synthesis accessible to non-experts [18] [19]. These drivers are catalyzing advances in drug discovery and materials science, enabling the rapid and safe production of novel functional molecules [20]. The fusion of automation with artificial intelligence and continuous flow technology is redefining the pace and possibilities of chemical synthesis [18] [21].

Key Drivers in Automated Synthesis

Reproducibility

Automated platforms provide unparalleled reproducibility by executing syntheses with digital precision, eliminating human variability [19].

- Precision and Digital Protocols: Automated systems translate chemical procedures into precise, machine-readable code, ensuring identical execution every time [20]. The development of hardware-agnostic description languages like XDL (Chemical Description Language) allows for the creation of standardized, reproducible synthetic protocols [20].

- Closed-Loop Optimization: Advanced systems incorporate real-time analytical feedback (e.g., via in-line IR spectroscopy) and algorithms like Bayesian optimization to self-correct and optimize reaction parameters, ensuring consistent output of target compounds like plasmonic nanoparticles [21].

Safety

Automation enhances laboratory safety by handling hazardous reagents and intermediates without direct human intervention [19].

- Containment of Hazardous Materials: Continuous flow systems safely generate and consume reactive, toxic, or explosive intermediates within confined channels [22]. This is critically demonstrated in the automated synthesis of unstabilized diazo compounds for pyrazoline production, which are considered high-energy and hazardous [22].

- Minimized Operator Exposure: From stock containers to final product, material transport occurs within a closed system, drastically reducing the risk of exposure [19].

Democratizing Innovation

Automation democratizes molecular innovation by lowering barriers for non-experts and accelerating discovery [20] [23].

- Accessibility via Natural Language: New frameworks like the LLM-based Reaction Development Framework (LLM-RDF) allow chemists to control automated platforms using natural language, eliminating the need for specialized programming skills [23].

- Rapid Exploration of Chemical Space: High-throughput automated platforms enable the rapid synthesis and screening of vast libraries of molecules, such as generating twenty 2-pyrazolines quickly and reliably [22]. This accelerates the iterative "design-make-test-analyze" cycles central to drug discovery [23].

Quantitative Comparison of Automated Synthesis Platforms

The choice between batch and continuous flow automation depends on the specific application requirements. The table below summarizes the performance and characteristics of representative platforms from the literature.

Table 1: Performance Comparison of Automated Synthesis Platforms

| Platform Type | Target Molecule/Nanoparticle | Key Performance Metric | Analysis Method | Primary Advantages | Key Limitations |

|---|---|---|---|---|---|

| Batch (AI-Guided) [21] | Silver Nanoparticles | Optimization within 200 iterations | Online UV-Vis Spectroscopy | AI-guided self-optimization | Limited to a single analytical technique |

| Batch (Machine Learning-Assisted) [21] | Gold Nanoparticles | 95% yield | Online Real-Time Spectroscopic Feedback | High reproducibility with AI | Requires offline validation (e.g., electron microscopy) |

| Continuous Flow [22] | 2-Pyrazolines | 7.71 g in 2.5 hours (scale-up) | In-line IR Spectroscopy | Safe handling of unstabilized diazo intermediates; Scalability | Potential for reactor clogging |

| Continuous Flow (Microfluidic) [21] | Gold, Silver Nanoparticles | Precise size control (4-100 nm) | Inline UV-Vis Spectroscopy | Modular "plug-and-play" system; Enhanced reproducibility | Limited morphological insights without offline characterization |

Detailed Experimental Protocol: Automated Multistep Synthesis of 2-Pyrazolines in Continuous Flow

This protocol, adapted from Labes et al., details the automated synthesis of 2-pyrazolines from aldehydes via unstabilized diazo intermediates, showcasing principles of safety, reproducibility, and automation [22].

Principle

The protocol involves a telescoped three-step continuous flow process: (1) hydrazone formation from an aldehyde and hydrazine, (2) oxidation of the hydrazone to an unstabilized diazo compound using a packed-bed MnO2 column, and (3) a [3+2] cycloaddition between the diazo compound and a dipolarophile (e.g., an alkene) to form the 2-pyrazoline product [22].

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials and Reagents

| Item Name | Function/Application in the Protocol |

|---|---|

| Aldehyde Starting Material | Core building block for hydrazone and subsequent diazo compound formation. |

| Hydrazine Solution (1 mol L⁻¹ in THF) | Reagent for hydrazone formation; requires solvent system modification (10% MeOH) for pump compatibility [22]. |

| Manganese Dioxide (MnO₂) | Packed-bed solid oxidant for converting hydrazones to reactive diazo intermediates. |

| Triethylamine (TEA) in MeOH | Column conditioning agent to neutralize acidic sites on MnO₂, improving reactivity [22]. |

| Dipolarophile (e.g., Acrylonitrile, Ethyl Acrylate) | Electron-deficient alkene that undergoes [3+2] cycloaddition with the diazo compound to form the 2-pyrazoline core. |

| Solvent System (THF/MeOH, 9:1) | Reaction solvent that ensures solubility of intermediates and final product. |

Equipment Setup

- Continuous Flow System (e.g., Vapourtec R-Series) equipped with:

- Reciprocating piston pumps (one modified for hydrazine handling).

- A sample injection loop.

- A column (e.g., 10 mm i.d.) packed with MnO2 powder.

- PFA tubing reactor coils.

- An in-line IR spectrometer (e.g., Mettler Toledo FlowIR).

- A collection vessel maintained under N2 atmosphere at 0°C.

Procedure

Step 1: System Preparation and Column Activation

- Flush the entire flow system with the THF/MeOH (9:1) solvent mixture.

- Activate the MnO2 packed-bed column by pumping a solution of triethylamine (TEA) in methanol through it for 3 minutes. This pre-conditioning step neutralizes acidic sites and is more efficient than previous methods [22].

Step 2: Hydrazone Formation (Step 1 of 3)

- Prepare a solution of the aldehyde starting material in the THF/MeOH solvent system.

- In a separate stream, pump the hydrazine solution (1 mol L⁻¹ in THF).

- Use a T-mixer to combine the aldehyde and hydrazine streams.

- Pass the combined stream through a reactor coil at room temperature. Monitor the reaction in real-time using the in-line FlowIR by observing the disappearance of the carbonyl stretch (~1700 cm⁻¹) [22].

Step 3: Diazo Compound Generation (Step 2 of 3)

- Direct the hydrazone stream from Step 2 through the activated MnO2 packed-bed column.

- The eluting stream will turn a characteristic bright orange, pink, or red, indicating the formation of the unstabilized diazo intermediate. Caution: Do not isolate this intermediate.

Step 4: [3+2] Cycloaddition & Product Collection (Step 3 of 3)

- Immediately after the MnO2 column, use another T-mixer to combine the diazo-containing stream with a solution of the dipolarophile (e.g., acrylonitrile) in solvent.

- Pass the combined stream through a final reactor coil to allow the cycloaddition to proceed.

- Collect the output stream in a single vessel containing the dipolarophile, maintained under a nitrogen atmosphere at 0°C for safety [22].

Step 5: System Re-set and Library Synthesis

- After collection is complete, wash the system with the THF/MeOH solvent mixture for 5 minutes.

- The system is now ready for the next experiment. To generate a library of different 2-pyrazolines, simply load a new aldehyde into the injection loop and repeat from Step 2 [22].

Workflow Visualization

The following diagram illustrates the logical flow and hardware configuration of the automated continuous flow synthesis.

Diagram Title: Automated Continuous Flow Synthesis of 2-Pyrazolines

Emerging Frontiers: AI and LLM Integration

The next evolutionary step in automated synthesis is the integration of Artificial Intelligence (AI) and Large Language Models (LLMs), moving from simple automation to full autonomy [20] [23].

- AI-Driven Self-Optimization: Platforms now use algorithms, such as Bayesian optimization and genetic algorithms, to autonomously search for optimal reaction conditions. For instance, AI-guided batch reactors can optimize silver nanoparticle synthesis within 200 iterations, defining a target morphology without extensive human intervention [21].

- LLM-Based Copilots: Frameworks like the LLM-based Reaction Development Framework (LLM-RDF) use multiple specialized AI agents (e.g., Literature Scouter, Experiment Designer, Hardware Executor) to guide the entire synthesis development process—from literature search and experimental design to hardware control and data analysis—via natural language commands [23]. This significantly lowers the technical barrier for chemists.

Automated multistep synthesis is fundamentally advancing small molecule research by ensuring reproducible results, providing a safer working environment, and democratizing access to complex molecular innovation. As these intelligent platforms continue to evolve, integrating more sophisticated AI and user-friendly interfaces, they promise to redefine the role of the chemist and dramatically accelerate the pace of discovery in fields like pharmaceutical development [20] [23].

Platforms in Practice: A Comparative Guide to Automated Synthesis Technologies and Their Applications

The synthesis of complex small molecules remains a rate-limiting step in drug discovery and materials science. Traditional approaches require customized routes for each target, a process that is time-intensive and demands specialist expertise [24]. Drawing inspiration from the modular biosynthesis of natural products and the automated synthesis of biomacromolecules, iterative cross-coupling (ICC) has emerged as a unifying strategy for small molecule construction [24] [25]. At the heart of this strategy are N-methyliminodiacetic acid (MIDA) boronates, which serve as stable, bifunctional building blocks. Their unique stability profile allows for the sequential, iterative formation of carbon-carbon bonds, typically via Suzuki-Miyaura cross-coupling, in a controlled manner [24] [26]. A critical enabler of automation for this platform is the development of a "catch-and-release" purification protocol, which exploits the specific adsorption of MIDA boronates to silica gel under precise solvent conditions [25]. This article details the application notes and protocols for implementing MIDA boronate-based ICC with integrated catch-and-release purification, framed within the broader pursuit of automated, multi-step synthesis platforms for small molecule research [20].

Protocols and Methodologies

Synthesis of MIDA Boronate Building Blocks

MIDA boronates are readily prepared from boronic acids or via other routes. The following protocol is adapted from standard literature procedures [24].

Protocol 1: Synthesis of MIDA Boronates via Condensation.

- Objective: To convert a boronic acid into the corresponding MIDA boronate.

- Materials: Boronic acid, N-methyliminodiacetic acid (MIDA), anhydrous toluene, anhydrous DMSO, molecular sieves (4 Å).

- Procedure:

- Combine the boronic acid (1.0 equiv), MIDA (1.1 equiv), and molecular sieves in a round-bottom flask.

- Add a solvent mixture of anhydrous toluene and DMSO (typically 10:1 to 20:1 v/v) to fully suspend the solids.

- Fit the flask with a Dean-Stark apparatus and reflux condenser. Heat the mixture to reflux (110-140 °C) under an inert atmosphere (N₂ or Ar).

- Reflux until water evolution ceases (typically 2-24 hours).

- Cool the reaction mixture to room temperature and filter to remove molecular sieves.

- Concentrate the filtrate under reduced pressure.

- Purify the crude product by crystallization (e.g., from acetone/Et₂O) or silica gel chromatography using eluents such as Hexanes/EtOAc or DCM/MeOH [24].

- Note: Alternative methods include transmetalation from organosilanes or cross-metathesis with vinyl MIDA boronate [24].

General Iterative Cross-Coupling (ICC) Cycle

The ICC cycle involves three key operations per building block addition: deprotection, coupling, and purification [25].

Protocol 2: One Cycle of Iterative Cross-Coupling.

- Objective: To couple a halide-terminated growing chain (Intermediate) with a bifunctional MIDA boronate building block.

- Materials: MIDA-protected intermediate, Bifunctional MIDA boronate (Halide-R-B(MIDA)), Pd catalyst (e.g., Pd(PPh₃)₄ or Pd(dppf)Cl₂), Base (e.g., K₂CO₃, Cs₂CO₃), Anhydrous solvent (e.g., THF, 1,4-dioxane), Aqueous NaOH (1 M).

- Procedure:

- Deprotection: Dissolve the MIDA-protected intermediate in a mixture of THF and 1 M aqueous NaOH (e.g., 4:1 v/v). Stir vigorously at 23 °C for 30-60 minutes until hydrolysis to the corresponding boronic acid is complete. Extract the boronic acid into an organic solvent (e.g., EtOAc), dry (Na₂SO₄), and concentrate. Use immediately in the next step.

- Coupling: Transfer the crude boronic acid to a reaction vessel. Add the bifunctional MIDA boronate building block (1.1-1.5 equiv), Pd catalyst (2-5 mol%), and base (2.0-3.0 equiv). Evacuate and backfill with inert gas (N₂/Ar) three times. Add degassed anhydrous solvent and heat to 60-85 °C with stirring until the reaction is complete (monitor by TLC or LC-MS).

- Catch-and-Release Purification (Protocol 3): Purify the reaction mixture directly via the catch-and-release protocol to isolate the new MIDA-protected elongated intermediate.

Catch-and-Release Silica Gel Purification

This protocol is essential for automation, enabling the isolation of the MIDA boronate product from excess reagents, catalyst, and byproducts without manual column chromatography [25].

Protocol 3: Catch-and-Release Purification of MIDA Boronates.

- Objective: To specifically isolate a MIDA boronate intermediate from a crude coupling reaction mixture.

- Materials: Crude reaction mixture, Silica gel (standard grade, e.g., SiO₂ 60 Å), Solvents: Diethyl ether (Et₂O), Methanol (MeOH), Tetrahydrofuran (THF).

- Procedure (Manual or Automated):

- Adsorption ("Catch"): Dilute the cooled crude reaction mixture with diethyl ether. Load this solution onto a column or cartridge packed with silica gel pre-equilibrated with diethyl ether. The MIDA boronate product binds tightly to the silica under these non-polar, ethereal conditions.

- Washing: Wash the column extensively with diethyl ether (or 9:1 Et₂O/MeOH) to elute all non-boronate impurities, including excess halide starting material, catalyst residues, and inorganic salts.

- Elution ("Release"): Switch the eluent to tetrahydrofuran (THF). The MIDA boronate product rapidly desorbs and elutes in a concentrated band. Monitor by TLC (DCM/MeOH eluent).

- Concentration: Collect the THF eluate and concentrate under reduced pressure to obtain the purified MIDA boronate intermediate, which is ready for the next ICC cycle.

- Key Insight: The purification leverages the unique and strong adsorption of the trigonal pyramidal MIDA boronate complex to silica in ethers, contrasting with the weaker binding of most other organic species [25].

Data Presentation

Table 1: Methods for the Synthesis of MIDA Boronate Building Blocks [24]

| Method | Starting Material | Key Conditions | Example Product | Notes |

|---|---|---|---|---|

| Condensation | Boronic Acid | MIDA, Dean-Stark, Toluene/DMSO | Aryl-/Alkenyl-B(MIDA) | Most common method; requires water removal. |

| Bromoboration-Trapping | Alkyne | BBr₃, then MIDA/2,6-lutidine | (E)-Alkenyl-B(MIDA) | Stereospecific, gives E-alkenes. |

| Transmetalation | Organotrimethylsilane | BBr₃, then Na₂(MIDA) | Vinyl-B(MIDA) | Useful for unstable boronic acids. |

| Cross-Metathesis | Olefin | Vinyl-B(MIDA), Grubbs Catalyst | Alkenyl-B(MIDA) | Avoids boronic acid intermediates; E-selective. |

Table 2: Scope and Impact of the MIDA Boronate ICC Platform [25]

| Metric | Data | Implication for Automated Synthesis |

|---|---|---|

| Estimated Coverage of Natural Products | 70-75% of ~260,000 known structures | Demonstrates the generalizability of the approach for diverse targets. |

| Required Building Blocks for Full Coverage | ~5,000 MIDA Boronates | Defines the scope of the necessary chemical inventory. |

| Commercially Available Building Blocks (c. 2017) | ~200 MIDA Boronates | Highlights a then-current bottleneck for widespread adoption. |

| Purification Method | Solvent-switch "Catch-and-Release" on silica | Enables full automation of the most challenging step in iterative synthesis. |

The Scientist's Toolkit: Key Reagents & Materials

| Item | Function in ICC & Purification | Key Properties & Notes |

|---|---|---|

| MIDA Boronate Building Blocks | Bifunctional substrates containing both a halide (X) and a protected boronate (B(MIDA)). The core unit for iterative assembly. | Stable, crystalline solids. Compatible with silica gel chromatography. The MIDA ligand is stable to cross-coupling conditions but hydrolyzes under mild aqueous base [24]. |

| Palladium Catalysts (e.g., Pd(PPh₃)₄) | Mediates the Suzuki-Miyaura cross-coupling reaction between the in-situ generated boronic acid and the halide of the incoming building block. | Standard catalysts are effective. Must be compatible with the MIDA protecting group. |

| Silica Gel (SiO₂) | Stationary phase for the catch-and-release purification. Selectively adsorbs the MIDA boronate complex in diethyl ether. | Standard chromatography-grade silica is effective. The mechanism relies on specific interaction with the MIDA-B structure [25]. |

| Diethyl Ether (Et₂O) | "Catch" solvent. Creates conditions for strong, selective adsorption of the MIDA boronate to silica. | Must be anhydrous to prevent premature hydrolysis of the MIDA boronate. |

| Tetrahydrofuran (THF) | "Release" solvent. Disrupts the MIDA boronate-silica interaction, leading to rapid elution of the pure product. | Polar ethereal solvent that successfully competes for binding to the boronate complex. |

| Aqueous Sodium Hydroxide (1M) | Deprotection agent. Hydrolyzes the MIDA boronate to the reactive boronic acid needed for coupling. | Mild aqueous base; reaction is typically fast at room temperature [24]. |

Workflow Visualization

Diagram 1: One Cycle of Iterative Cross-Coupling with Integrated Purification

Diagram 2: Mechanism of Silica Gel Catch-and-Release Purification

Continuous-flow synthesis has emerged as a transformative platform in modern chemical research and industrial manufacturing, particularly for the automated multistep synthesis of small molecules. This technology performs chemical reactions through the continual input of starting materials and continuous output of products within narrow tubes or reactors under strictly controlled conditions [27]. The integration of continuous-flow systems with automation and real-time analytics addresses critical bottlenecks in traditional batch processing, enabling more efficient access to complex molecular architectures with unprecedented control over reaction parameters [28] [13].

For researchers in drug development, continuous-flow chemistry offers distinct advantages for handling highly reactive intermediates, performing challenging transformations, and streamlining the transition from laboratory discovery to industrial production [28]. The technology's inherent safety features, combined with superior heat and mass transfer capabilities, make it particularly valuable for synthesizing pharmaceutical intermediates and active pharmaceutical ingredients (APIs) where control over exothermic reactions and reactive species is paramount [29] [30]. This application note details specific protocols and case studies demonstrating how continuous-flow synthesis enhances safety, scalability, and reaction efficiency within automated multistep synthesis workflows for small molecule research.

Fundamental Advantages of Continuous-Flow Systems

Enhanced Safety Profiles

Continuous-flow chemistry significantly improves safety for chemical synthesis, especially when dealing with hazardous reagents or conditions. The small internal volume of flow reactors minimizes the quantity of reactive material present at any given time, substantially reducing potential risks [31]. This characteristic enables the safe handling of highly pyrophoric reagents, explosive intermediates, and exothermic reactions that would be challenging or impractical in traditional batch reactors [28]. The ability to precisely control residence time and temperature further mitigates risks associated with unstable intermediates or side products [31].

Superior Scalability and Process Intensification

Flow chemistry enables seamless translation from laboratory research to industrial production through process intensification rather than simple scale-up. Once optimal conditions are established in a laboratory flow reactor, production scale can be increased by extending operation time ("numbering up") without re-optimizing reaction parameters [28] [31]. This approach maintains consistent reaction performance and product quality across scales, addressing a significant challenge in pharmaceutical development where traditional batch processes often require extensive re-optimization during scale-up [31].

Improved Reaction Efficiency and Control

The enhanced mass and heat transfer characteristics of continuous-flow systems lead to improved reaction efficiency, selectivity, and yields [28] [27]. The high surface-area-to-volume ratio of microreactors enables exceptional thermal control, which is particularly advantageous for exothermic reactions where efficient heat dissipation prevents localized overheating and improves safety [28]. Precise control over residence time allows researchers to work with reaction times ranging from milliseconds to hours, enabling the generation and immediate consumption of highly reactive intermediates that would be unstable under standard batch conditions [28].

Table 1: Quantitative Comparison of Batch vs. Continuous-Flow Synthesis for Pharmaceutical Applications

| Parameter | Batch Synthesis | Continuous-Flow Synthesis | Improvement Factor |

|---|---|---|---|

| Heat transfer efficiency | Limited by reactor size | Enhanced via high surface-to-volume ratio | 100-1000x increase [28] |

| Scale-up time | Months to years | Days to weeks | 3-5x faster [28] |

| Reaction control | Limited | Precise control of time, temperature, mixing | Significant enhancement [27] |

| Hazardous reagent handling | Challenging, requires special equipment | Enabled via small hold-up volumes | Substantial safety improvement [31] |

| Material efficiency | Variable | Highly consistent | Improved yield and selectivity [30] |

Application Notes: Key Transformations in Flow

Organometallic Transformations

The integration of organometallic chemistry with continuous-flow methodologies has advanced significantly, enabling efficient access to highly reactive intermediates that are challenging to handle under batch conditions [28]. Key transformations that benefit from flow approaches include:

Halogen-metal exchange reactions demonstrate particular advantages in flow systems. These fast, highly exothermic reactions benefit from the superior mixing efficiency and precisely controlled short residence times achievable in microreactors [28]. Pioneering work has demonstrated the ultrafast generation of organolithium intermediates on the order of milliseconds, followed by immediate quenching with electrophiles to prevent decomposition [28]. This approach enables cryogen-free metalations and safe handling of highly reactive species.

Directed metalation and transmetalation processes also show significant improvements in flow systems. The use of lithium and magnesium bases for deprotonation of organic substrates achieves superior regioselectivity in flow, often circumventing the need for cryogenic temperatures [28]. Transmetalation reactions benefit from rapid mixing and short residence times, significantly reducing side reactions typically associated with reactive organolithium intermediates when trapped with magnesium or zinc salts [28].

Photochemical Transformations

Flow chemistry significantly enhances photochemical processes that face limitations in traditional batch reactors due to poor light penetration and non-uniform irradiation [31]. The minimized light path length and precise control over irradiation time in flow photochemical reactors lead to improved selectivities and conversions, particularly valuable at larger scales [31].

Recent advances combine high-throughput experimentation (HTE) with flow photochemistry to rapidly identify optimal reaction conditions. Automated platforms can screen multiple photocatalysts, bases, and reagents efficiently, significantly reducing optimization time [31]. This approach has been successfully applied to complex transformations such as flavin-catalyzed photoredox fluorodecarboxylation, where initial HTE identification of optimal conditions enabled successful scale-up to kilogram-scale production [31].

Nitration Chemistry

Nitration of aromatic compounds represents a transformation particularly well-suited to continuous-flow processing due to significant safety advantages and improved selectivity. Traditional batch nitration methods often face challenges with high safety risks, environmental concerns, and poor mononitration selectivity [30].

Recent developments have established scalable and sustainable continuous-flow microreaction processes for mononitration of aromatic compounds with high selectivity and yield [30]. This technology has been successfully applied to the synthesis of various mononitro compounds, including nitro-p-xylene, nitro-o-xylene, nitro-chlorobenzene, and nitro-toluene, with yields exceeding 95% in many cases [30]. The process has been demonstrated on scales up to 800 g h⁻¹, with consistent or improved performance compared to small-scale experiments [30]. Additionally, integrated waste acid recycling strategies enhance economic benefits while reducing environmental impact [30].

Table 2: Performance Metrics for Continuous-Flow Nitration of Aromatic Compounds [30]

| Substrate | Product | Yield (%) | Selectivity | Throughput |

|---|---|---|---|---|

| p-Xylene | Nitro-p-xylene | >95% | Excellent | 800 g h⁻¹ |

| o-Xylene | Nitro-o-xylene | >95% | Excellent | 800 g h⁻¹ |

| Chlorobenzene | Nitro-chlorobenzene | >95% | Excellent | Scalable |

| Toluene | Nitro-toluene | >95% | Excellent | Scalable |

| Erlotinib intermediate | Nitro intermediate | 99.3% | Excellent | Scalable |

Experimental Protocols

General Continuous-Flow Setup and Operation

Materials and Equipment:

- Syringe or piston pumps for reagent delivery

- Microreactor (stainless steel, glass, or polymer)

- Mixing unit (T-mixer or micromixer)

- Temperature control unit (heating/cooling)

- Back pressure regulator

- Inline analytical instrumentation (optional)

- Product collection vessel

Procedure:

- System Assembly: Connect all components in sequence: reagent reservoirs → pumps → mixing unit → reactor → back pressure regulator → product collection.

- System Priming: Prime all flow paths with appropriate solvents to remove air bubbles and ensure proper wetting of all surfaces.

- Parameter Setting: Set desired flow rates to achieve target residence time, reactor temperature, and system pressure.

- Reaction Initiation: Switch reagent streams from priming solvent to reaction mixtures once stable conditions are established.

- Process Monitoring: Monitor system pressure and temperature continuously to ensure stable operation. Utilize inline analytics if available.

- Product Collection: Collect product stream in appropriate vessel. For multistep sequences, direct output to subsequent reaction steps.

- System Shutdown: Flush system with clean solvent before disassembly and storage.

Safety Considerations:

- Always install pressure relief devices for safe operation

- Conduct initial trials with small quantities to assess reactivity

- Implement leak detection and emergency shutdown procedures

- Use appropriate personal protective equipment when handling reagents and products

Protocol: Halogen-Lithium Exchange and Electrophilic Quenching

This protocol details a representative organolithium transformation demonstrating the safety advantages of continuous-flow processing for highly exothermic reactions with sensitive intermediates [28].

Diagram 1: Halogen-Lithium Exchange Workflow showing reagent mixing, lithiation, electrophilic quenching, and inline purification steps.

Reagents and Materials:

- Aryl halide substrate (1.0 M in THF)

- Organolithium reagent (1.1 M in hexanes)

- Electrophile (1.5 M in appropriate solvent)

- Anhydrous tetrahydrofuran (THF)

- Aqueous workup solutions (1M HCl, saturated NaHCO₃, brine)

Equipment:

- Dual-channel syringe or piston pumps

- Microreactor assembly (0.5-5.0 mL volume)

- T-mixer for reagent combining

- Cryostat for temperature control (-78°C capability)

- Back pressure regulator (50-200 psi)

- Inline quenching module

Procedure:

- Solution Preparation: Prepare all reagent solutions under inert atmosphere using standard Schlenk techniques or glovebox.

- System Setup: Assemble flow path with temperature control maintaining the initial reactor section at -78°C.

- Flow Rate Calibration: Set flow rates to achieve desired stoichiometry (typically 1.0:1.1:1.5 molar ratio for aryl halide:organolithium:electrophile) and residence time of 1-30 seconds for the lithiation step.

- Reaction Execution: Simultaneously pump aryl halide and organolithium solutions through the T-mixer into the primary reactor.

- Intermediate Quenching: Direct the organolithium intermediate stream to mix with electrophile solution in the second reactor.

- Residence Time Control: Maintain appropriate residence time (typically 1-10 minutes) in the quenching reactor.

- Product Collection: Collect output stream directly into aqueous workup solution or proceed to inline purification.

- Analysis: Characterize products using standard analytical techniques (NMR, LC-MS, HPLC).

Troubleshooting:

- Precipitation Issues: Increase solvent concentration or incorporate anti-fouling reactor designs

- Low Conversion: Optimize residence time, temperature, or reagent stoichiometry

- Product Variability: Ensure consistent temperature control and mixing efficiency

Protocol: Continuous-Flow Mononitration of Aromatic Compounds

This protocol describes a scalable continuous-flow process for mononitration of aromatic compounds with high selectivity and yield, based on recently published methodology [30].

Reagents and Materials:

- Aromatic substrate (e.g., p-xylene, chlorobenzene)

- Mixed acid nitrating agent (H₂SO₄/HNO₃)

- Dichloromethane or other suitable solvent

- Aqueous sodium bicarbonate solution (5%)

- Brine solution

Equipment:

- Corrosion-resistant flow reactor (Hastelloy, PTFE, or glass)

- Dual reagent feed system

- Temperature-controlled reactor module

- Inline separator for acid/organic phase separation

- Product collection vessel

Procedure:

- Solution Preparation: Prepare organic phase containing aromatic substrate (1.0 M in dichloromethane) and nitrating agent (3:1 v/v H₂SO₄:HNO₃).

- System Setup: Assemble flow path with corrosion-resistant components and temperature control maintaining reactor at 40-70°C.

- Flow Rate Calibration: Set flow rates to achieve desired residence time (typically 2-5 minutes) and stoichiometry.

- Reaction Execution: Pump organic and acid phases through mixing element into the temperature-controlled reactor.

- Phase Separation: Direct output through inline membrane separator or centrifugal separator.

- Acid Recycling: Route separated acid phase to recovery system or collection for reuse.

- Product Isolation: Wash organic phase with aqueous NaHCO₃ solution followed by brine in inline extraction units.

- Solvent Removal: Remove solvent using falling film evaporator or rotary evaporation.

- Analysis: Characterize products using GC, GC-MS, or HPLC to determine yield and selectivity.

Key Advantages:

- Excellent mononitration selectivity (>95%)

- High yields (>95%)

- Scalable to 800 g h⁻¹ throughput

- Integrated acid recycling reduces waste

- Enhanced safety profile compared to batch nitration

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for Continuous-Flow Synthesis

| Reagent/Material | Function | Application Examples | Safety Considerations |

|---|---|---|---|

| Organolithium reagents (n-BuLi, t-BuLi) | Halogen-lithium exchange, deprotonation | Synthesis of pharmaceutical intermediates [28] | Highly pyrophoric; flow enables safe handling [28] |

| Mixed acid nitrating agents (HNO₃/H₂SO₄) | Electrophilic aromatic substitution | Mononitration of aromatic compounds for pharmaceuticals, agrochemicals [30] | Highly corrosive; exothermic reactions; flow minimizes hazardous inventory [30] |

| Photocatalysts (flavins, ruthenium, iridium complexes) | Photoredox catalysis | Fluorodecarboxylation, C-H functionalization [31] | Flow enables efficient light penetration and uniform irradiation [31] |

| Gaseous reagents (CO, O₂, H₂) | Reaction components | Carbonylation, oxidation, hydrogenation | Flow enables precise control of gas-liquid mixing and stoichiometry [29] |

| Heterogeneous catalysts (packed beds) | Catalysis | Hydrogenation, cross-coupling reactions | Eliminates catalyst separation steps; enables continuous operation [28] |

Implementation and Scale-up Strategies

Successful implementation of continuous-flow synthesis requires careful consideration of reactor design, process parameters, and scale-up strategies. The modular nature of flow systems enables gradual scale-up from laboratory research to industrial production through several approaches:

Lab-Scale Development (mg-g scale): Initial reaction screening and optimization conducted in microreactors with internal volumes of 10-1000 μL. This stage focuses on identifying optimal reaction parameters, including temperature, residence time, and stoichiometry [28] [31].

Pilot-Scale Demonstration (10-100 g scale): Translation of optimized conditions to mesofluidic reactors with increased throughput. This stage validates scalability and addresses potential challenges such as fouling, precipitation, or mixing efficiency [30].

Production-Scale Implementation (kg-tonne scale): Implementation in industrial-scale continuous-flow reactors, often using parallel reactor units or extended operation time. This stage demonstrates economic viability and process robustness for manufacturing [30] [31].

Process Analytical Technology (PAT) plays a crucial role in continuous-flow synthesis, enabling real-time monitoring and control of critical quality attributes. Inline spectroscopy (NMR, IR, UV-Vis), chromatography (HPLC, UPLC), and mass spectrometry provide immediate feedback on reaction progress and product quality, facilitating rapid optimization and ensuring consistent output [13] [31].

The integration of flow chemistry with automated synthesis platforms represents the cutting edge of pharmaceutical research. Systems such as the Chemputer enable standardized, reproducible execution of complex multistep syntheses with minimal human intervention [13]. These platforms combine automated reaction execution with inline analytics and purification, significantly accelerating the discovery-development-manufacturing pipeline for small molecule therapeutics [13] [1].