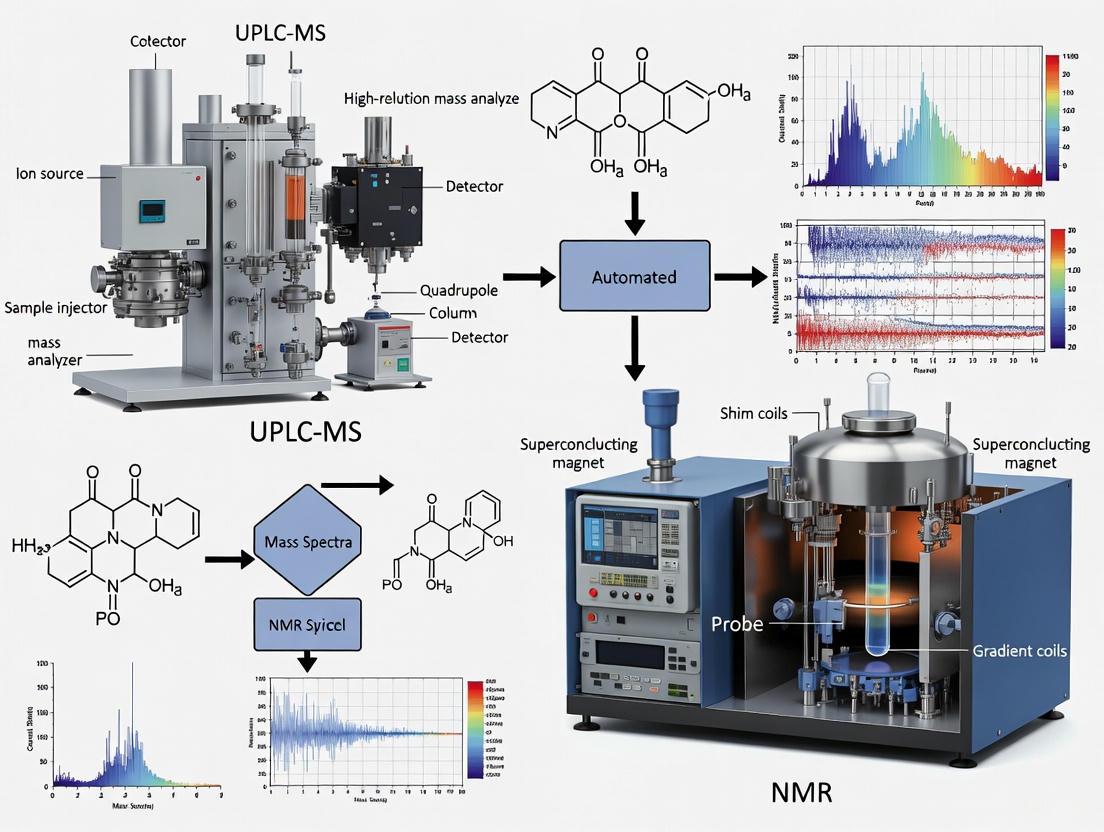

Automated Reaction Monitoring: Integrating UPLC-MS and NMR for Smarter Chemical Synthesis

This article explores the transformative integration of UPLC-MS and NMR spectroscopy for automated reaction monitoring, a cornerstone of modern high-throughput research in drug development and chemical synthesis.

Automated Reaction Monitoring: Integrating UPLC-MS and NMR for Smarter Chemical Synthesis

Abstract

This article explores the transformative integration of UPLC-MS and NMR spectroscopy for automated reaction monitoring, a cornerstone of modern high-throughput research in drug development and chemical synthesis. We cover the foundational principles of these techniques, highlighting their complementary strengths: UPLC-MS for high sensitivity and metabolite coverage, and NMR for superior reproducibility and non-targeted structural analysis. The piece provides a detailed guide to configuring automated workflows, from robotic sample handling to software integration, and addresses key troubleshooting and optimization strategies. Finally, it offers a comparative analysis of the techniques and examines validation protocols, providing researchers and scientists with a comprehensive resource to enhance efficiency, reproducibility, and data-driven decision-making in their labs.

The Pillars of Automation: Understanding UPLC-MS and NMR Synergy

Core Principles of UPLC-MS and NMR in Reaction Monitoring

In modern drug development, the design-make-test-analyze (DMTA) cycle is a foundational process for rapid compound optimization. A significant bottleneck in this cycle has traditionally been the purification and structural verification of synthesized compounds. The deep fusion of Ultra-Performance Liquid Chromatography-Mass Spectrometry (UPLC-MS) and Nuclear Magnetic Resonance (NMR) spectroscopy within automated, high-throughput platforms addresses this challenge directly [1] [2]. These intelligent automated systems provide a solid technical foundation, offering unique advantages of low consumption, low risk, high efficiency, high reproducibility, high flexibility, and good versatility [1]. This article details the core principles and application protocols for leveraging UPLC-MS and NMR in automated reaction monitoring, providing researchers with the methodologies to innovate material manufacturing and redefine the pace of chemical synthesis.

Core Principles and Instrumentation

Principles of UPLC-MS

UPLC-MS combines the superior separation power of ultra-performance liquid chromatography with the identification and quantification capabilities of mass spectrometry. The principles of UPLC-MS can be broken down into two main components:

- Ultra-Performance Liquid Chromatography (UPLC): UPLC operates on the same fundamental principles as HPLC but utilizes stationary phases with smaller particle sizes (typically below 2 µm) and higher operating pressures. This results in significantly improved chromatographic resolution, increased speed of analysis, and enhanced sensitivity. Compounds are separated based on their differential partitioning between a stationary phase (the column) and a mobile phase (the solvent).

- Mass Spectrometry (MS): Following chromatographic separation, analytes are ionized (typically by electrospray ionization - ESI), and their mass-to-charge ratios (m/z) are measured. This provides molecular mass information and, through tandem MS (MS/MS), characteristic fragmentation patterns for definitive identification.

The synergy of these techniques allows for the precise separation, detection, and identification of compounds in complex mixtures, making it indispensable for monitoring reaction progress and purity.

Principles of NMR Spectroscopy

Nuclear Magnetic Resonance (NMR) spectroscopy is a powerful analytical technique that provides detailed structural and quantitative information about molecules.

- Fundamental Principle: NMR exploits the magnetic properties of certain atomic nuclei, such as ^1H and ^13C. When placed in a strong magnetic field, these nuclei can absorb electromagnetic radiation at a characteristic frequency. The resulting NMR spectrum reveals a wealth of information, including:

- Chemical Shift: Provides information on the chemical environment of a nucleus.

- Spin-Spin Coupling: Reveals the connectivity between atoms within a molecule.

- Signal Intensity: Is directly proportional to the concentration of the nuclei, enabling quantification.

- Advantages for Reaction Monitoring: Unlike MS, NMR is nondestructive and excels at distinguishing between isomers (e.g., regioisomers, stereoisomers) and providing direct evidence of molecular structure and connectivity [2]. Its main historical limitations in high-throughput workflows have been lower sensitivity and the need for deuterated solvents.

Synergy in an Automated Workflow

UPLC-MS and NMR are highly complementary techniques. While UPLC-MS excels at rapid purity assessment and providing molecular mass information, NMR delivers unambiguous structural confirmation [2]. In an automated platform, samples can be routed from a UPLC-MS system to an NMR spectrometer, enabling a seamless workflow where the strengths of one technique compensate for the weaknesses of the other. This provides researchers with a complete analytical dataset—purity, molecular identity, and definitive structure—from a single, integrated process.

Experimental Protocols

UPLC-MS Protocol for Metabolite Identification

This protocol is adapted from a detailed method for metabolite analysis using a Thermo Fisher Q-Exactive HF Orbitrap mass spectrometer [3].

1. Sample Preparation:

- Dissolve or dilute reaction mixtures or crude samples in a solvent compatible with the mobile phase (e.g., water/acetonitrile).

- Centrifuge if necessary to remove particulate matter.

2. UPLC Conditions:

- System: Ultimate 3000 UPLC or equivalent.

- Column: Reverse-phase (e.g., Waters ACQUITY UPLC BEH C18, 2.1 × 50 mm, 1.7 µm).

- Mobile Phase A: Water/Acetonitrile (40:60 v/v) with 10 mM ammonium formate and 0.1% formic acid.

- Mobile Phase B: Acetonitrile/2-Propanol (10:90 v/v) with 10 mM ammonium formate and 0.1% formic acid.

- Gradient: Optimize for specific application (e.g., a 3.0 min fast gradient for high-throughput analysis or an 8.5 min gradient for more complex mixtures) [3] [2].

- Column Temperature: 55 °C.

- Auto-sampler Temperature: 5 °C.

- Injection Volume: 5 µL (for reverse-phase).

3. MS Conditions:

- Mass Spectrometer: High-resolution accurate mass instrument (e.g., Q-Exactive HF Orbitrap).

- Ionization Mode: Electrospray Ionization (ESI), positive or negative mode.

- Data Acquisition:

- Full Scan: For accurate mass measurement.

- Data-Dependent Acquisition (DDA): Top 5 DDA to automatically select and fragment the most abundant ions. Use stepped normalized collision energy (e.g., 10, 30, and 50 V) to generate rich MS/MS spectra [3].

- Parallel Reaction Monitoring (PRM): For targeted analysis, use a collision energy ramp (e.g., 10 to 40 V) [3].

4. Data Analysis:

- Use software to process chromatograms and mass spectra.

- Identify compounds based on retention time, accurate mass, and MS/MS fragmentation patterns compared to standards or databases.

Table 1: UPLC-MS Method Parameters for Reaction Monitoring

| Parameter | Specification | Purpose |

|---|---|---|

| Column Type | Reverse Phase (C18), 2.1 x 50 mm, 1.7 µm | High-resolution, fast separation |

| Mobile Phase A | Water/Acetonitrile with ammonium formate & formic acid | Aqueous phase, aids ionization |

| Mobile Phase B | Acetonitrile/2-Propanol with ammonium formate & formic acid | Organic phase, efficient elution |

| Gradient Time | 3.0 min (fast) to 8.5 min (comprehensive) | Balances throughput vs. resolution |

| MS Detection | High-resolution Orbitrap | Accurate mass and MS/MS data |

| Data Acquisition | DDA & PRM | Untargeted discovery & targeted quantification |

Automated NMR Sample Generation and Acquisition

This protocol describes an automated workflow for generating NMR samples from the "dead volume" of purification systems, enabling high-throughput structural verification without consuming material prioritized for biological assays [2].

1. Integrated Purification and NMR Sampling:

- Purification Scale: The workflow is applicable to multiple scales: Traditional (tPMC, 50-75 μmol), Analytical (aPMC, 10-30 μmol), and Micro (μPMC, 3-5 μmol) [2].

- Dead Volume Recovery: After UPLC-MS purification and fraction collection, the inaccessible "dead volume" in the vials (∼25 μL for traditional, ∼10 μL for analytical/micro scales) is rescued instead of being discarded.

- Sample Dilution: A liquid handling robot (e.g., Tecan) automatically adds 250 μL of DMSO to the vials containing the dead volume, creating a ready-to-analyze NMR sample [2].

2. NMR Acquisition Parameters:

- Sample Tube: Use 1.7 mm NMR tubes for high-throughput analysis to minimize sample volume and increase throughput.

- Spectrometer: High-field NMR spectrometer (e.g., 500 MHz or higher) equipped with an automated sample changer.

- Experiment Type:

- ¹H NMR: Standard one-dimensional proton NMR. This is the primary experiment for structural verification.

- Acquisition Parameters: Number of scans (NS) = 16-128; relaxation delay (D1) = 1-5 seconds. Parameters can be optimized for sensitivity and throughput.

- Automated Processing: Utilize automated Fourier transformation, phasing, and peak picking software. Integrate with structure verification algorithms for rapid analysis.

3. Data Interpretation:

- Manually or automatically review the ¹H NMR spectrum for the presence of expected signals and the absence of impurities or starting materials.

- Use the structural information to confirm the identity of the synthesized compound, particularly to distinguish isomeric products that UPLC-MS cannot.

Table 2: Key Parameters for Automated High-Throughput NMR

| Parameter | Specification | Purpose |

|---|---|---|

| Sample Source | Dead volume from purification | Uses otherwise wasted material |

| NMR Tube Diameter | 1.7 mm | Minimizes sample requirement, increases throughput |

| Deuterated Solvent | DMSO-d₆ | Standard solvent compatible with workflow |

| Throughput | Up to 36,000 compounds/year | Supports parallel medicinal chemistry (PMC) |

| Primary Experiment | ¹H NMR | Rapid structural confirmation |

| Automation | Liquid handling & auto-sampler | Enables high-throughput, minimal manual intervention |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for UPLC-MS and NMR Reaction Monitoring

| Item | Function / Application |

|---|---|

| UPLC BEH C18 Column (1.7 µm) | Provides high-resolution separation of reaction components under reverse-phase conditions [3]. |

| Ammonium Formate / Formic Acid | Mobile phase additives that improve chromatographic peak shape and enhance ionization efficiency in positive ESI-MS [3]. |

| 10 mM DMSO Stock Solutions | Standardized concentration for reformatting purified compounds for biological testing and storage; compatible with both assays and NMR [2]. |

| 1.7 mm NMR Tubes | Enables NMR data acquisition from minimal sample volumes (as low as 10 µg), which is critical for high-throughput microscale synthesis [2]. |

| Charged Aerosol Detector (CAD) | Provides mass-based quantification of compounds without UV chromophores, essential for accurate yield determination after purification [2]. |

| DMSO-d₆ | Standard deuterated solvent for NMR spectroscopy, allowing for sample locking and shimming without the need for extensive sample preparation from DMSO stocks [2]. |

Workflow Visualization

The following diagram illustrates the integrated automated workflow for reaction monitoring, purification, and analysis that synergizes UPLC-MS and NMR.

Integrated Automated Analysis Workflow

This workflow demonstrates how a sample progresses from submission through automated purification, with parallel tracks for biological testing and structural verification via NMR, all coordinated by a central LIMS [2].

Why Combine UPLC-MS and NMR? Defining Complementary Roles

The integration of Ultra-Performance Liquid Chromatography-Mass Spectrometry (UPLC-MS) and Nuclear Magnetic Resonance (NMR) spectroscopy represents a transformative approach in modern analytical chemistry, particularly for automated reaction monitoring in drug discovery and development. This application note delineates the complementary roles of these techniques, providing detailed experimental protocols and data comparison tables to guide researchers in implementing this powerful synergistic workflow. By leveraging the high sensitivity of UPLC-MS alongside the structural elucidation capabilities of NMR, scientists can achieve comprehensive molecular characterization of complex reaction mixtures with unprecedented efficiency.

In pharmaceutical research and development, the imperative to understand chemical processes thoroughly demands analytical techniques that provide both rapid detection and definitive structural characterization. UPLC-MS and NMR spectroscopy have emerged as cornerstone technologies for reaction monitoring, yet each possesses distinct strengths and limitations [4] [5]. The integration of these platforms creates a synergistic workflow that surpasses the capabilities of either technique used in isolation.

UPLC-MS delivers exceptional sensitivity, with limits of detection in the femtomole range for analytes with high ionization efficiency, enabling rapid analysis of complex mixtures [4] [6]. However, MS alone cannot readily distinguish isobaric compounds or positional isomers and provides limited structural information without authentic standards [4]. Conversely, NMR spectroscopy offers unparalleled structural elucidation power, distinguishing between isomers and providing atomic connectivity information through multidimensional experiments [4] [7]. Despite being less sensitive (typically requiring microgram quantities) and slower than MS, NMR is inherently quantitative, non-destructive, and unaffected by matrix effects [4] [8].

This application note, framed within broader thesis research on automated reaction monitoring, delineates practical strategies for combining UPLC-MS and NMR, complete with detailed protocols, comparative data tables, and visualization tools to guide implementation in drug development settings.

Complementary Analytical Strengths

Technical Comparison

Table 1: Comparative analytical profiles of UPLC-MS and NMR spectroscopy

| Parameter | UPLC-MS | NMR |

|---|---|---|

| Detection Limits | Femtomole range (10⁻¹³ mol) [4] | Microgram range (10⁻⁹ mol) [4] |

| Structural Information | Molecular weight, elemental composition, fragmentation patterns [4] | Atomic connectivity, stereochemistry, functional groups, isomer distinction [4] [7] |

| Quantitation | Relative quantitation; suffers from matrix effects and ionization efficiency variations [4] | Inherently quantitative; direct proportionality between signal and concentration [4] [8] |

| Analysis Speed | Seconds to minutes per sample [6] | Minutes to hours for 1D spectra; hours to days for 2D experiments [4] |

| Sample Preservation | Destructive analysis [9] | Non-destructive; sample recovery for further analysis [4] |

| Isomer Differentiation | Limited capability [4] | Excellent capability [4] |

Synergistic Applications in Reaction Monitoring

The combination of UPLC-MS and NMR enables comprehensive reaction monitoring that capitalizes on their complementary strengths:

- Reaction Progression Tracking: UPLC-MS provides rapid assessment of starting material consumption and product formation, while NMR delivers quantitative concentration data and identifies isomeric products [6] [8].

- Intermediate Identification: NMR can characterize transient reactive intermediates with sufficient lifetimes, while MS detects these species based on mass signatures [7] [8].

- Impurity Profiling: MS excels at detecting low-abundance impurities, while NMR determines their structures, including stereochemistry [6] [7].

- Mechanistic Elucidation: The combination provides both kinetic data (from NMR) and molecular weight information (from MS) for comprehensive reaction mechanism understanding [8].

Figure 1: Complementary data workflow for UPLC-MS and NMR in reaction monitoring

Experimental Protocols

UPLC-MS Reaction Monitoring Protocol

Application: Rapid screening of reaction progression and component detection [6]

Materials:

- ACQUITY UPLC System with BEH C8 Column (2.1 × 30 mm, 1.7 μm)

- SQ Mass Detector with ESI source

- Mobile Phase A: 0.1% Formic acid in water

- Mobile Phase B: 0.1% Formic acid in acetonitrile

Method Parameters:

- Column Temperature: 45°C

- Flow Rate: 800 μL/min

- Gradient: 5% to 95% B over 0.7 minutes

- Injection Volume: 1-5 μL

- MS Acquisition: 100-1300 m/z at 10,000 amu/sec

Procedure:

- Sample Preparation: Withdraw aliquot from reaction mixture, filter through 0.2 μm membrane, and dilute with appropriate solvent.

- System Equilibration: Condition UPLC system with initial mobile phase composition for 0.5 minutes.

- Sample Analysis: Inject prepared sample using specified gradient method.

- Data Acquisition: Acquire data in both positive and negative ionization modes simultaneously.

- Data Processing: Use automated software (e.g., OpenLynx) for peak detection and identification.

Key Advantages: Rapid analysis (cycle time <1.5 minutes) enables high-throughput screening of multiple reaction timepoints [6].

NMR Reaction Monitoring Protocol

Application: Structural elucidation and quantitative reaction profiling [7] [8]

Materials:

- NMR spectrometer (400-800 MHz) with flow probe or flow tube

- Deuterated solvent (e.g., CD₃CN, D₂O)

- Peristaltic pump for continuous flow

- Reactor vessel with temperature control

Method Parameters:

- Flow Rate: 1-2 mL/min (continuous circulation)

- NMR Acquisition: 1D ¹H NMR with solvent suppression

- Relaxation Delay: 1-2 seconds between scans

- Number of Scans: 4-16 for adequate signal-to-noise

- Acquisition Time: 2-3 minutes per time point

Procedure:

- System Setup: Connect reactor to NMR flow cell using appropriate tubing, ensuring continuous circulation.

- Deuterium Lock: Incorporate approximately 10% deuterated solvent in reaction mixture for field frequency lock.

- Initial Shimming: Optimize magnetic field homogeneity before reaction initiation.

- Kinetic Profiling: Acquire sequential ¹H NMR spectra throughout reaction duration.

- Data Processing: Use automated integration software (e.g., Mnova) to track concentration changes of specific resonances over time.

- Structural Analysis: For unknown intermediates, perform stopped-flow 2D experiments (e.g., COSY, HSQC).

Key Advantages: Non-invasive analysis provides true picture of reaction composition without perturbation; quantitative data enables kinetic studies [8].

Integrated UPLC-MS-NMR Workflow

Application: Comprehensive reaction analysis for complex or problematic reactions

Materials:

- Combined UPLC-MS and NMR systems

- LC-NMR interface with peak trapping capability

- Deuterated mobile phase components

Procedure:

- Initial Screening: Use UPLC-MS to identify optimal timepoints for detailed analysis based on reaction profile.

- Peak Selection: Based on MS data, select chromatographic peaks of interest for NMR analysis.

- Loop Collection: Trap relevant LC peaks in storage loops for subsequent offline NMR analysis.

- NMR Analysis: Transfer trapped peaks to NMR flow cell for structural characterization.

- Data Correlation: Integrate MS and NMR datasets for complete molecular understanding.

Key Advantages: Combines sensitivity of MS with structural power of NMR; ideal for identifying unknown impurities, metabolites, or reactive intermediates [4] [10].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key research reagent solutions for UPLC-MS-NMR reaction monitoring

| Item | Function | Application Notes |

|---|---|---|

| Deuterated Solvents (e.g., CD₃CN, D₂O) | Provides NMR field frequency lock without significant interference | Enables real-time NMR monitoring; cost can be managed using only partially deuterated solvents (10% in protonated solvent) [8] |

| Formic Acid (MS grade) | Mobile phase modifier for improved ionization in MS | Enhances protonation in positive ion mode; concentration typically 0.1% [6] |

| UPLC-MS Columns (C8 or C18, 1.7-1.8 μm) | High efficiency chromatographic separation | Sub-2μm particles provide narrow peaks (<1 sec width); requires high pressure systems [6] |

| NMR Flow Cells | Enables continuous monitoring without manual sampling | Can be fixed flow cell probes or modified NMR tubes; active volumes as low as 1.5 μL available [4] [8] |

| Solvent Suppression Sequences | Reduces strong solvent signals in NMR | Essential for observing analyte signals in non-deuterated or partially deuterated solvents [8] |

| Cryogenically Cooled Probes | Enhances NMR sensitivity | Reduces electronic noise; provides 2-4x sensitivity improvement compared to conventional probes [4] [10] |

| Automated Data Processing Software | Handles large datasets from continuous monitoring | Processes hundreds of spectra; aligns peaks with shifting chemical shifts; extracts kinetic profiles [8] |

Figure 2: Integrated NMR reaction monitoring setup for continuous flow analysis

The strategic integration of UPLC-MS and NMR technologies creates a powerful platform for automated reaction monitoring that transcends the limitations of either technique used independently. This synergistic approach enables researchers to rapidly identify reaction components with high sensitivity (UPLC-MS) while definitively characterizing their structures, including isomeric forms and reactive intermediates (NMR). The experimental protocols and technical comparisons provided in this application note offer practical guidance for implementing this workflow in drug discovery and development environments. As pharmaceutical research continues to emphasize efficiency and comprehensive process understanding, the combined UPLC-MS-NMR approach represents an essential methodology for advancing reaction optimization and mechanistic elucidation.

The global market for automated reaction monitoring is experiencing robust growth, driven by the increasing need for accelerated innovation and stringent quality control across life sciences, energy, and materials sectors. This field has become a cornerstone for organizations aiming to maintain a competitive edge, with advances in analytical technologies enabling real-time observation of reaction pathways, kinetics, and yield optimization [11]. The market is shifting from traditional end-point analysis to continuous monitoring, fundamentally reshaping how scientists approach process development, scale-up, and quality control [11].

Quantitative market data reveals a strong upward trajectory, as detailed in Table 1 below.

Table 1: Reaction Monitoring Market Size and Projections

| Metric | 2024 Value | 2025 Value | Projected 2032 Value | CAGR (2025-2032) |

|---|---|---|---|---|

| Global Market Size | USD 1.85 billion | USD 1.97 billion | USD 3.14 billion | 6.86% [11] |

This growth is segmented across various industries and product types, with the pharmaceutical and biotechnology sector representing the largest market share due to its demand for high-throughput analysis in drug development [11] [12]. The market's concentration and key characteristics are summarized in Table 2.

Table 2: Market Segmentation and Key Characteristics

| Segment | Dominant Players/Areas | Market Characteristics & Concentration |

|---|---|---|

| End-User Industries | Pharmaceutical & Biotechnology, Academic Research, Clinical Diagnostics [12] | Pharmaceutical sector is the largest revenue generator; clinical diagnostics shows rapid growth potential [12]. |

| Product Types | Mass Spectrometers, Software, Reagents & Consumables [12] | High-end mass spectrometers hold significant share; consumables market is substantial and crucial for growth [12]. |

| Regional Adoption | North America, Europe, Asia-Pacific [11] [12] | North America holds largest share; Asia-Pacific expected to see fastest growth rate [12]. |

| Innovation Focus | Sensitivity, Selectivity, Automated Data Analysis, Multiplexing [12] | Driven by demand for high-throughput screening and user-friendly software [11] [12]. |

Experimental Protocol: Automated Reaction Monitoring with Inline NMR

The following detailed protocol describes a methodology for the self-optimization of a flow reactor using inline benchtop NMR, as exemplified by the Knoevenagel condensation model reaction [13]. This protocol integrates hardware, software, and analytical techniques to create a closed-loop, automated system.

Principle

A self-optimizing flow reactor system integrates real-time analytics with an intelligent optimization algorithm. The system continuously monitors reaction output via inline NMR spectroscopy and uses a Bayesian algorithm to adjust reaction parameters automatically, seeking optimal performance with minimal human intervention [13]. This approach is highly suited for accelerated reaction development and optimization.

Materials and Equipment

Reagents and Compounds:

- Salicylaldehyde (104.5 mL, 1 mol) [13]

- Ethyl acetoacetate (126.5 mL, 1 mol) [13]

- Piperidine (9.88 mL, 10 mol%) as catalyst [13]

- Ethyl Acetate (HPLC grade) [13]

- Acetone (HPLC grade) [13]

- Dichloromethane [13]

Instrumentation:

- Flow Reactor System: Ehrfeld Micro Reaction System (MMRS) including micromixer and capillary reactor [13]

- Pumps: Three SyrDos syringe pumps [13]

- Automation & Control: HiTec Zang LabManager and LabVision software [13]

- Inline Analyzer: Magritek Spinsolve 80 Ultra Benchtop NMR Spectrometer [13]

- Optional: Tecan liquid handling robot for sample reformatting [2]

Procedure

Step 1: System Setup and Configuration

- Prepare Feed Solutions:

- Feed 1: Dissolve salicylaldehyde (104.5 mL, 1 mol) and piperidine (9.88 mL, 10 mol%) in ethyl acetate to a final volume of 1 L.

- Feed 2: Dissolve ethyl acetoacetate (126.5 mL, 1 mol) in ethyl acetate to a final volume of 1 L.

- Dilution Feed: Mix dichloromethane (8.0 mL, 125 mmol) with acetone to a final volume of 1 L [13].

Assemble Flow Reactor: Connect the feed lines via the micromixer to the capillary reactor, maintained at a constant temperature. Connect the outlet to a second mixer where the dilution feed is added, and then route the stream through the NMR flow cell [13].

Configure Software: Establish communication between the LabManager automation system and the Spinsolve NMR spectrometer using the external control mode. Pre-load a quantitative NMR (qNMR) template in the Spinsolve software with acquisition parameters (e.g., 1D EXTENDED+ protocol, 4 scans, 6.55 s acquisition time) [13].

Step 2: Method Definition and Algorithm Calibration

- Define Variable Parameters: Set the optimization algorithm to vary the flow rates of Feed 1 and Feed 2 within a range of 0 to 1 mL/min. This manipulates both the reactant ratio and the residence time [13].

Set Optimization Goal: Configure the algorithm to maximize the reaction yield, which will be calculated from the real-time NMR data [13].

Steady-State Criteria: Program the system to take consecutive NMR measurements at each set of conditions until three consecutive readings show no significant change in conversion and yield, indicating a steady state has been reached [13].

Step 3: Execution of the Automated Optimization Run

- Initiate Optimization: Start the automated run via the LabVision software. The system will begin with an initial set of conditions.

Data Acquisition and Analysis: For each iteration:

- The LabManager triggers the Spinsolve NMR to acquire a spectrum.

- The qNMR software automatically analyzes the spectrum, calculating the conversion and yield based on defined integrals (e.g., aldehyde proton from starting material and olefinic proton from the product) [13].

- The yield data is passed back to the LabVision software.

Iterative Feedback Loop: The Bayesian optimization algorithm in LabVision analyzes the yield result and calculates a new, potentially better set of flow rate parameters. The LabManager then implements these new settings on the syringe pumps, and the loop repeats [13].

Step 4: Data and Output Handling

- Monitor Progress: Track the yield as a function of the iteration number. The algorithm will balance "exploration" (testing new regions of parameter space) and "exploitation" (refining known promising conditions) [13].

- Final Output: The system will run for a pre-defined number of iterations or until convergence criteria are met. The conditions corresponding to the highest yield achieved are identified as the optimal parameters [13].

The workflow of this automated system is illustrated in the following diagram:

Calculations

NMR Yield and Conversion Calculations for Knoevenagel Model Reaction:

- Reference Integral (R): Aromatic region (6.6 - 8.10 ppm), representing 4 protons constant in both starting material and product.

- Starting Material Integral (S1): Aldehyde proton of salicylaldehyde (9.90 - 10.20 ppm).

- Product Integral (S2): Olefinic proton of 3-acetyl coumarin (8.46 - 8.71 ppm).

Conversion of salicylaldehyde is calculated as:

Conversion (%) = [1 - (S1 / R)] × 100% [13]

Yield of 3-acetyl coumarin is calculated as:

Yield (%) = (S2 / R) × 100% [13]

The Scientist's Toolkit: Essential Research Reagent Solutions

The implementation of robust automated reaction monitoring platforms relies on a suite of essential reagents, instruments, and software. Table 3 details these key components and their functions in the experimental workflow.

Table 3: Key Research Reagent Solutions for Automated Reaction Monitoring

| Tool Name/Category | Function in Workflow | Specific Examples & Notes |

|---|---|---|

| Benchtop NMR Spectrometer | Provides real-time, non-destructive structural analysis and quantification directly in the reaction stream [13]. | Magritek Spinsolve Ultra; operates without cryogens, can be installed in a fume hood, does not require deuterated solvents for locking [13]. |

| Process Automation & Control Software | The central "brain" that integrates hardware, controls parameters, acquires data, and executes optimization algorithms [13]. | HiTec Zang LabManager (hardware) and LabVision (software); enables flexible configuration and recipe control for R&D [13]. |

| Microreactor Flow System | Provides a controlled environment for reactions with enhanced heat/mass transfer and seamless integration with analytics [13]. | Ehrfeld Modular Microreactor System (MMRS); includes micromixers and capillary reactors [13]. |

| Bayesian Optimization Algorithm | Intelligently navigates the parameter space by balancing exploration and exploitation to find optimal conditions with fewer experiments [13]. | Integrated into control software (e.g., LabVision); uses yield data to propose subsequent reaction parameters [13]. |

| Syringe Pumps with High Precision | Deliver reactants and dilution solvents at precisely controlled flow rates, a key variable for optimization [13]. | SyrDos syringe pumps; capable of varying flow rates between 0-1 mL/min as directed by the automation system [13]. |

| Deuterated Solvents for NMR | Used in the analyte for frequency lock and shimming in high-field NMR; not required for benchtop NMR operation [13] [14]. | Deuterated methanol (CD₃OD) or D₂O can be used in extraction for LC-MS/NMR cross-platform work [14]. |

| Laboratory Information Management System (LIMS) | Manages sample tracking, data analysis, and generates instructions for automated equipment in high-throughput workflows [2]. | Internal systems used in pharma (e.g., at Pfizer) to handle purification, characterization, and plate management for thousands of compounds [2]. |

| UPLC-MS Systems | Offers high-sensitivity, high-throughput analysis for qualitative and quantitative analysis of reaction mixtures, often used alongside NMR [15] [2]. | Waters UPLC systems coupled to MS detectors; used for purity assessment and method development in purification workflows [2]. |

This application note details the pivotal role of Ultra-Performance Liquid Chromatography coupled with Mass Spectrometry (UPLC-MS) in modern metabolomics and automated reaction monitoring, emphasizing its core advantages of exceptional sensitivity and broad metabolite coverage. Within the broader research context integrating UPLC-MS and benchtop NMR for automated synthesis and real-time analysis, these strengths enable unprecedented insight into complex chemical and biological systems [16].

Analytical Superiority and Quantitative Data

UPLC-MS represents a significant evolution from conventional LC-MS, offering superior chromatographic resolution, speed, and sensitivity. These improvements directly translate to enhanced detection and quantification of metabolites, which is critical for elucidating the multi-component, multi-target mechanisms of action in systems like traditional Chinese medicine (TCM) and for monitoring reaction pathways in real-time [17] [18].

Table 1: Key Performance Advantages of UPLC-MS in Metabolite Analysis

| Aspect | Capability/Advantage | Impact on Research |

|---|---|---|

| Chromatographic Resolution | Sub-2µm particle columns; higher peak capacity. | Reduces co-elution, improves separation of isomeric compounds, leading to cleaner spectra and more accurate quantification [17] [18]. |

| Analysis Speed | Significantly reduced run times compared to HPLC. | Enables high-throughput (HT) analysis of large sample cohorts, essential for biobank studies and rapid reaction screening [18] [16]. |

| Detection Sensitivity | Enhanced signal-to-noise due to sharper peak elution. | Lowers limits of detection (LOD), allowing quantification of low-abundance metabolites and transient reaction intermediates [17] [18]. |

| Metabolite Coverage | Compatible with diverse separation modes (RP, HILIC). | Expands the analytical space to cover metabolites across a wide polarity range, from lipids to polar organic acids [17]. |

| Data Quality for Informatics | Produces high-resolution, precise m/z and retention time data. | Provides robust input for computational tools like asari, improving feature detection accuracy and reproducibility in metabolomics [19]. |

Detailed Experimental Protocols for Metabolite Profiling

The following protocol outlines a standardized workflow for UPLC-MS-based untargeted metabolomics, which forms the basis for applications in drug discovery and reaction monitoring.

Protocol: Untargeted Metabolic Profiling Using UPLC-HRMS

A. Sample Preparation (Critical for Coverage & Sensitivity)

- Quenching & Homogenization: Rapidly quench metabolic activity in biological samples (e.g., cells, tissues) using liquid nitrogen or cold methanol. Homogenize the sample to ensure uniform extraction and maximize metabolite recovery [17].

- Metabolite Extraction:

- Employ a biphasic solvent system for comprehensive coverage. A typical method uses a methanol/water/chloroform mixture (e.g., 2.5:1:1 ratio) [17].

- Vigorously vortex, then centrifuge (e.g., 14,000 x g, 15 min, 4°C) to separate phases.

- For polar metabolite analysis, collect the upper aqueous-methanol layer. For lipid analysis, collect the lower organic (chloroform) layer.

- Dry the extracts under a gentle stream of nitrogen or using a vacuum concentrator.

- Reconstitution: Reconstitute dried extracts in a solvent compatible with the chromatographic method (e.g., 100 µL of water/acetonitrile (98:2) for HILIC-MS; acetonitrile/water (50:50) for RPLC-MS). Centrifuge to remove particulates before injection [17].

B. UPLC-HRMS Analysis

- Chromatography:

- System: UPLC system equipped with a high-pressure capable binary pump.

- Columns: Use sub-2µm particle columns. For reversed-phase (RP), a C18 column (e.g., 2.1 x 100 mm, 1.7 µm) is standard. For hydrophilic interaction (HILIC), a bridged ethylene hybrid (BEH) amide column is recommended [17].

- Gradient: Employ optimized gradients. Example RP gradient: 1-99% acetonitrile (with 0.1% formic acid) in water over 10-15 minutes. Maintain a constant column temperature (e.g., 40°C) [18].

- Mass Spectrometry:

- Instrument: High-resolution mass spectrometer (e.g., Q-TOF, Orbitrap) capable of data-dependent acquisition (DDA) or data-independent acquisition (DIA) [17] [18].

- Ionization: Use electrospray ionization (ESI) in both positive and negative modes to maximize metabolite coverage.

- Acquisition Parameters: Set resolution > 35,000 FWHM; mass range 50-1200 m/z. Use automatic gain control (AGC) and optimized collision energies for MS/MS fragmentation.

C. Data Processing & Feature Extraction

- Convert raw data to an open format (e.g., mzML) using tools like

msConvert[19]. - Process data using a reproducible algorithm like

asari. Key steps include mass alignment via "mass tracks," which treats m/z alignment independently from and prior to elution peak detection, enhancing consistency and selectivity (mSelectivity) [19]. - Perform peak picking, alignment across samples, and gap filling to generate a feature intensity table (m/z, RT, intensity).

Visualizing the Integrated Workflow

UPLC-MS in Automated Reaction Monitoring Workflow

High-Resolution Metabolomics Data Processing Logic

The Scientist's Toolkit: Essential Research Reagents & Solutions

Table 2: Key Reagents and Materials for UPLC-MS Metabolomics & Reaction Monitoring

| Item | Function & Description | Application Context |

|---|---|---|

| Cold Quenching Solvents | Methanol, acetonitrile (pre-chilled to -80°C). Stops enzymatic activity instantly to preserve the in vivo metabolic state [17]. | Sample preparation for cellular/tissue metabolomics. |

| Biphasic Extraction Solvents | Methanol/Water/Chloroform mixtures. Enables simultaneous extraction of polar and non-polar (lipid) metabolites, maximizing coverage [17]. | Comprehensive metabolite profiling. |

| UPLC Columns (Sub-2µm) | e.g., C18 (RP), BEH Amide (HILIC). Provides high chromatographic resolution and peak capacity for separating complex mixtures [17] [18]. | Core separation component in UPLC-MS systems. |

| High-Purity Calibrants & QCs | Stable isotope-labeled internal standards (SIL-IS), pooled quality control (QC) samples. Essential for instrument calibration, monitoring performance, and ensuring data quality in large studies [20] [18]. | All quantitative MS applications. |

| Automated Synthesis & Sampling Platform | e.g., FLEX ISYNTH with integrated fluidics and valve systems. Enables reproducible, high-throughput reaction execution and automated aliquot sampling for online analysis [21] [16]. | Automated reaction monitoring and optimization. |

| Integrated Analytics Module | Interface coupling automated sampler to UPLC-MS and/or benchtop NMR (e.g., Fourier 80). Allows for complementary, real-time analysis of reaction progress and components [16]. | Multi-modal reaction monitoring. |

| Reproducible Data Processing Software | e.g., asari (open-source). Performs trackable and scalable processing of LC-MS data with improved feature correspondence and mSelectivity [19]. |

Metabolomics data extraction and analysis. |

| Interactive Dashboard Tools | e.g., Dash/Plotly-based QC dashboards. Visualizes instrument performance metrics (peak area, RRT) over time, enabling proactive maintenance [20]. | Laboratory quality control and assurance. |

Application Note: The Central Pillar in Automated Reaction Monitoring Research

Within the framework of a thesis investigating integrated UPLC-MS and NMR platforms for automated reaction monitoring, Nuclear Magnetic Resonance (NMR) spectroscopy emerges as the indispensable technique for definitive structural characterization and ensuring data reproducibility. This application note delineates the core strengths of NMR in this context, providing detailed protocols and resources to empower research in pharmaceutical and chemical development.

Foundational Strengths: Why NMR is Irreplaceable

NMR spectroscopy provides atom-level insight into molecular structure, dynamics, and purity that is orthogonal and complementary to mass spectrometric data. Its non-destructive nature makes it ideal for continuous reaction monitoring and sample reuse [22] [23].

Table 1: Comparative Analytical Strengths of NMR in Integrated Workflows

| Feature | NMR Spectroscopy | Mass Spectrometry (MS) | Infrared (IR) Spectroscopy |

|---|---|---|---|

| Structural Detail | Full molecular framework, stereochemistry, conformation [22] | Molecular weight, fragmentation pattern [22] | Functional group identification [22] |

| Stereochemistry | Excellent (via NOESY/ROESY) [22] | Limited [22] | Not applicable [22] |

| Quantification | Accurate without external standards (qNMR) [24] [22] | Requires standards/calibrants [22] | Limited [22] |

| Impurity ID | High sensitivity to isomers, non-ionizables [22] | Sensitive to low-level impurities [22] | May miss low-level impurities [22] |

| Automation | High; integrated in benchtop & workflow automation [25] [26] | High | Moderate |

Table 2: Performance of Solvent Suppression Sequences for qNMR in Non-Deuterated Solvents Critical for high-throughput analysis in reaction monitoring where deuterated solvents may not be practical.

| Sequence Type | Key Principle | Robustness | Best Use Case | Reference |

|---|---|---|---|---|

| 1D-NOESYpr | Presaturation + z-filtering | Variable; sensitive to parameter setup | General metabolomics [24] | [24] |

| Binomial-like (e.g., WET, PURGE) | Selective excitation/suppression | High; produces robust quantitative results | High-accuracy qNMR [24] | [24] |

| Perfect-Echo based (e.g., PEW5, WADE) | Perfect echo scheme; active exchange broadening | Excellent at high field; reduces artifacts | High-field, aqueous samples [27] [24] | [27] [24] |

Core Experimental Protocols

Protocol 1: High-Accuracy Quantitative NMR (qNMR) for Reaction Yield Determination

Objective: To quantify reaction components accurately using an internal standard, enabling precise yield calculation during automated monitoring [24].

Materials & Sample Prep:

- Internal Standard: Maleic acid Certified Reference Material (CRM), precisely weighed [24].

- Sample: Reaction aliquot or purified product.

- Solvent: Can use non-deuterated solvent (e.g., H₂O) with appropriate suppression, or standard deuterated solvent [24].

- NMR Tube: Standard 5 mm or high-throughput tube.

Methodology:

- Weighing: Accurately weigh the internal standard and sample into an NMR vial. Use a calibrated balance with µg-mg resolution [24].

- Dissolution: Add solvent, vortex thoroughly for 1 minute to ensure complete dissolution and homogeneity [24].

- T₁ Measurement: Perform an inversion-recovery experiment to determine the longitudinal relaxation time (T₁) of the quantifiable signals for both the analyte and standard. Use a relaxation delay of ≥ 30 s [24].

- Quantitative Acquisition:

- Pulse Sequence: Use a binomial-like solvent suppression sequence (e.g., PURGE, WET) for highest accuracy in non-deuterated solvents [24]. For deuterated solvents, a standard zg pulse sequence is sufficient.

- Repetition Time (D1): Set to > 10 x the longest T₁ measured to ensure full relaxation [24].

- Scan Count (NS): Acquire sufficient scans to achieve a signal-to-noise ratio (SNR) > 250 for the target peaks.

- Spectral Width: 30 ppm.

- Data Points: 128k.

- Processing & Quantification:

- Process FID with exponential line broadening (LB = 0.3 Hz), Fourier Transform, phase correction, and baseline correction.

- Integrate relevant peaks for analyte and standard.

- Calculate concentration:

C_analyte = (I_analyte / I_std) * (N_std / N_analyte) * (M_std / M_analyte) * (W_std / W_sample), where I=integral, N=number of protons, M=molecular weight, W=weight.

Protocol 2: Automated Structural Dereplication via FID Reproc essing

Objective: To verify the identity of a reaction product by comparing its raw NMR data against a database, maximizing reproducibility [28].

Materials & Data:

- Raw Data: Free Induction Decay (FID) file of the unknown sample and reference compound(s) [28].

- Software: NMR processing software with advanced analysis capabilities (e.g., Mnova, TopSpin) [26].

- Database: Access to an NMR spectral database (e.g., NMRshiftDB, HMDB) [28].

Methodology:

- FID Acquisition: Ensure raw FID files are saved and archived from the automated reaction monitoring system.

- Reprocessing: Load the FID into processing software. Reprocess using different window functions (e.g., Lorentzian-to-Gaussian transformation) and zero-filling to enhance resolution [28].

- Advanced Analysis: Apply quantum mechanics-based fitting or multiplet analysis tools to extract precise chemical shifts (δ to 0.1-1 ppb) and coupling constants (J to 10 mHz) [28].

- Database Search: Use the extracted peak list or the processed spectrum to search against a unified spectral database (e.g., www.osdb.info, www.hmdb.ca) [28].

- Validation: Compare the unknown's raw FID or reprocessed spectrum with the reference FID from the database or literature. Overlay spectra and check for exact multiplet pattern matches, which are more diagnostic than tabulated shifts alone [28].

Visualization of Integrated Workflows

Diagram 1: Automated Reaction Monitoring with NMR and UPLC-MS Integration

Diagram 2: The FID Reproc essing Path for Structural Transparency

The Scientist's Toolkit: Essential Research Reagents & Solutions

Table 3: Key Reagents and Solutions for NMR in Automated Monitoring

| Item | Function & Specification | Application Context |

|---|---|---|

| Maleic Acid CRM | High-purity internal standard for qNMR; enables absolute quantification without identical analyte standard [24]. | Reaction yield determination, purity assessment. |

| Deuterated Solvents (D₂O, d₆-DMSO) | Provides lock signal for field stability; minimizes large solvent proton signals. | Standard high-resolution NMR analysis. |

| Non-Deuterated Solvents (H₂O) | Enables analysis in native reaction conditions; requires robust solvent suppression [24]. | Direct analysis of aqueous reaction mixtures, increased throughput. |

| qNMR Suitability Reference | Certified material (e.g., USP qNMR RS) for verifying instrument quantitative performance. | System suitability testing (SST) for validated workflows. |

| Cryoprobes & Inverse Probes | NMR probe hardware providing 4x sensitivity increase (cryoprobe) or optimized for ¹H detection. | Detecting low-concentration intermediates or products in reaction monitoring. |

| Automation-Compatible NMR Tubes | High-throughput, uniform tubes or flow cells for integrated systems. | Used in platforms like FLEX AUTOPLANT for online analysis [25]. |

| Mnova Gears / AUTOSUITE Software | Automation workflow software for batch NMR data processing, analysis, and reporting [25] [26]. | Pipelines for processing data from multiple reaction monitoring timepoints. |

| Spectral Databases (e.g., HMDB, OSDB) | Public repositories of NMR spectra and raw FIDs for dereplication [28]. | Verifying compound identity against known references. |

Protocol 3: PEARLScreen NMR for Ligand Screening in Fragment-Based Drug Discovery

Objective: To identify initial protein-ligand binding hits with high sensitivity using a perfect echo-based experiment, applicable in early-stage drug discovery research [27].

Materials:

- Protein target solution.

- Library of fragment compounds.

- NMR buffer (e.g., phosphate buffer, often in D₂O for lock).

- High-field NMR spectrometer (80 - 1200 MHz) [27].

Methodology:

- Sample Preparation: Prepare protein sample at low µM concentration (protocol allows for up to 40x reduction in protein requirement at high field) [27]. Mix with individual fragments or small mixtures.

- Experiment Setup: Select the PEARLScreen pulse sequence on the spectrometer [27].

- Acquisition Parameters: Utilize the perfect echo scheme. Key advantage is the use of longer relaxation delays and active exchange broadening to enhance binding sensitivity [27].

- Screening: Acquire ¹H spectra. Ligand binding is indicated by significant signal attenuation or line broadening for the fragment protons compared to a control spectrum without protein.

- Analysis: Use automated analysis software (e.g., Mnova Screen plugin) to rapidly process data and identify hits based on signal intensity changes [26].

Protocol 4: Archiving Raw FIDs for Reproducible Research

Objective: To adhere to Good Research Practices by preserving and sharing original NMR data to ensure long-term reproducibility and allow for re-analysis [28].

Methodology:

- Data Retention: Configure NMR software to automatically save the raw Free Induction Decay (FID) file in addition to the processed spectrum.

- Metadata Inclusion: Ensure the FID is accompanied by a complete set of acquisition parameters (pulse sequence, receiver gain, number of scans, etc.).

- Submission for Publication: As per emerging guidelines, submit the FID as part of the Supporting Information for publication. Annotate with the proposed structure [28].

- Deposition in Repository: Upload the FID to a public unified digital repository (e.g., Open Spectral Database - www.osdb.info) to assign a permanent access code [28].

- Citation: Reference the repository code in publications, allowing peers direct access to the primary data for verification or re-interpretation using advanced future methods [28].

The landscape of pharmaceutical analysis has undergone a fundamental transformation, shifting from manual, labor-intensive techniques to integrated, automated workflows that significantly accelerate drug discovery and development. This paradigm shift is particularly evident in the implementation of advanced analytical techniques such as Ultra-Performance Liquid Chromatography-tandem Mass Spectrometry (UPLC-MS/MS) and Nuclear Magnetic Resonance (NMR) spectroscopy. These technologies have evolved from standalone identification tools to core components of automated reaction monitoring systems, enabling real-time decision-making and high-throughput characterization in modern laboratories [29] [30] [31].

The driving force behind this transition stems from the pharmaceutical industry's need to overcome critical bottlenecks. Traditional methods struggled with throughput limitations, operator dependency, and delayed data availability, which impeded the rapid progression of drug candidates through development pipelines. Automated UPLC-MS/MS and NMR workflows now provide unprecedented efficiency in assessing critical parameters including solubility, metabolic stability, and impurity profiling, thereby compressing development timelines from months to weeks while delivering superior data quality and reproducibility [29] [31].

Automated UPLC-MS/MS for Solubility Screening

Protocol: Automated Solubility Screening Using UPLC-MS/MS

Application Note: High-throughput solubility determination for early-stage drug candidates [29]

Experimental Workflow:

Sample Preparation:

- Prepare stock solutions of test compounds at 5 mM concentration in DMSO using 96-well plates

- Transfer 50 μL aliquots of each stock solution to a 2-mL 96-well plate

- Add 950 μL of appropriate pH buffer (pH 1.0, 7.4, or 9.4) to each well, resulting in 250 μM compound concentration

- Shake gently for 1.5 hours at room temperature

- Vacuum-filter using Sirocco plates for 30-60 seconds into collection plates

- Dilute filtrates 1:100 in 50:50 acetonitrile/water for UPLC-MS/MS analysis

Standard Preparation:

- Prepare three-point calibration standards at 0.25 μM, 1.25 μM, and 2.5 μM concentrations

- Use serial dilutions from 5 mM DMSO stock solutions with 50:50 acetonitrile/water as diluent

UPLC Conditions:

- System: Waters ACQUITY TQD

- Column: ACQUITY UPLC BEH C18 (2.1 × 50 mm, 1.7 μm)

- Temperature: 40°C

- Flow Rate: 600 μL/min

- Mobile Phase A: 0.1% formic acid in water

- Mobile Phase B: 0.1% formic acid in acetonitrile

- Gradient: 5% to 95% B over 1.3 minutes

MS/MS Conditions:

- Ionization Mode: ESI Positive

- Capillary Voltage: 3200 V

- Source Temperature: 150°C

- Desolvation Temperature: 450°C

- Desolvation Gas: 900 L/hr

- Acquisition Mode: Multiple Reaction Monitoring (MRM)

- Dwell Time: 200 ms per transition

Data Analysis:

- Process data using ProfileLynx Application Manager

- Generate calibration curves for each compound from standard concentrations

- Automatically quantify analyte concentrations using established curves

- Multiply results by 100 (to account for dilution factor) to obtain final solubility values

- Flag values outside predetermined range (0.0-2.5 mg/mL) for review [29]

Table 1: Key Advantages of Automated UPLC-MS/MS Solubility Screening

| Parameter | Traditional Methods | Automated UPLC-MS/MS |

|---|---|---|

| Throughput | 10-20 samples/day | 96+ samples in single run |

| Sample Consumption | High (mL volumes) | Low (μL volumes) |

| Analysis Time | Hours to days | Minutes per sample |

| Detection Specificity | Moderate | High (MS/MS confirmation) |

| Dynamic Range | Limited | >3 orders of magnitude |

| Data Processing | Manual calculation | Automated reporting |

Automation Enablers in UPLC-MS/MS

The transformation to automated workflows has been facilitated by several key technological advancements. Software integration plays a pivotal role, with applications like QuanOptimize enabling automated MS method development and optimization, while ProfileLynx provides unified data processing and reporting across multiple assays [29]. This software integration eliminates manual intervention in method development and ensures consistency across analyses.

The implementation of Multiple Reaction Monitoring provides exceptional selectivity and sensitivity by targeting specific precursor-product ion transitions, enabling accurate quantification even in complex matrices [29] [15]. This approach has been successfully applied to multi-component analysis, simultaneously quantifying 22 marker compounds in traditional herbal formulations with high precision [15].

Furthermore, standardized data formats such as mzQuantML have been developed by the HUPO Proteomics Standards Initiative to capture quantitative outputs, supporting submissions to public repositories and enabling consistent data interpretation across platforms [32]. This standardization is crucial for reproducible automated workflows in regulated environments.

Automated NMR Workflows in Drug Development

Protocol: Quantitative NMR for Solubility and Physicochemical Properties

Application Note: Rapid determination of drug solubility and lipophilicity using automated qNMR [31]

Experimental Workflow:

Sample Preparation:

- Prepare saturated solutions of drug candidate by adding excess compound to aqueous buffer

- Agitate for 24 hours at constant temperature to achieve equilibrium

- Centrifuge at 15,000 × g for 10 minutes to separate undissolved material

- Transfer supernatant to NMR tube, adding internal standard (e.g., 3-(trimethylsilyl)propionic-2,2,3,3-d4 acid, sodium salt)

- For log P determinations, prepare samples in octanol-water systems and analyze both phases

NMR Acquisition Parameters:

- Instrument: High-field NMR spectrometer (≥400 MHz)

- Probe: Inverse detection cryoprobe for enhanced sensitivity

- Temperature: Controlled at 25°C or 37°C

- Pulse Sequence: Standard ¹H pulse sequence with pre-saturation for water suppression

- Relaxation Delay: ≥5 × T₁ (longest relaxation time)

- Acquisition Time: 2-4 seconds

- Scans: 16-64 depending on concentration

Data Processing:

- Process spectra with exponential multiplication (line broadening 0.3-1.0 Hz)

- Apply Fourier transformation and phase correction

- Reference spectra to internal standard signal

- Integrate target compound peaks and internal standard peak

- Calculate concentration using equations:

[ C{sample} = \frac{I{sample} \times N{std} \times m{std} \times P{std}}{I{std} \times N{sample} \times M{std}} \times 10^9 ]

Where: (C{sample}) = sample concentration (μg/mL) (I) = integral area (N) = number of nuclei contributing to signal (m{std}) = mass of internal standard (g) (M{std}) = molar mass of internal standard (g/mol) (P{std}) = purity of internal standard [31]

Automation Features:

- Automated sample changing with robotic sample handlers

- Automated locking, shimming, and calibration

- Pre-defined acquisition protocols for consistent data quality

- Automated data processing and quantification scripts

- Direct export of results to laboratory information management systems

Table 2: Research Reagent Solutions for Automated Analytical Workflows

| Reagent/Software | Function | Application |

|---|---|---|

| ProfileLynx | Automated data processing and reporting | UPLC-MS/MS solubility screening |

| QuanOptimize | MS method development and optimization | MRM parameter optimization |

| TopSpin | NMR data acquisition and processing | Automated NMR analysis |

| MNova | NMR data processing and quantification | qNMR analysis |

| mzQuantML | Standardized data representation | SRM data exchange and storage |

| Skyline | Targeted mass spec data analysis | SRM/MRM data processing |

Automation Enablers in NMR Spectroscopy

The automation of NMR workflows has been accelerated by several complementary technologies. Robotic sample handling enables continuous operation with automated loading, locking, shimming, and calibration, significantly increasing throughput for routine analyses [33] [31].

The implementation of quantitative NMR methodologies leverages the inherent quantitative nature of NMR signals, where peak areas directly correlate to the number of nuclei, enabling concentration determination without compound-specific calibration curves [31]. This approach is particularly valuable for simultaneous multi-component analysis in complex mixtures.

Advanced computational methods including quantum chemical calculations and machine learning algorithms have revolutionized NMR data interpretation. Density Functional Theory enables accurate prediction of NMR parameters, while machine learning approaches automate spectral analysis and facilitate structural elucidation of complex molecules [34]. These computational tools have dramatically reduced the expertise barrier and time investment required for NMR data interpretation.

Integrated Workflows and Data Management

Protocol: Automated SRM Data Analysis Workflow for Targeted Proteomics

Application Note: Large-scale targeted proteomic studies using automated SRM data analysis [35]

Experimental Workflow:

Data Processing:

- Convert raw SRM data to mzXML format

- Import transition lists in tab-separated format

- Execute mProphet for peptide identification via probabilistic scoring

- Perform peak picking and integration of transition chromatograms

Statistical Analysis:

- Process data with SRMstats using linear mixed-effect models

- Define experimental design with biological and technical replicates

- Calculate significance analysis for protein quantification changes

- Adjust p-values for multiple testing using false discovery rate control

Data Dissemination:

- Export results in standardized mzQuantML format

- Submit data to PASSEL repository for public access

- Generate summary reports for experimental interpretation

Timeline:

- Complete workflow execution: 1-2 weeks

- Processing time dependent on number of replicates and sample size [35]

Workflow Visualization

Diagram 1: Integrated UPLC-MS/NMR Automated Workflow

The paradigm shift from manual to automated analytical workflows represents a fundamental transformation in pharmaceutical research and development. By integrating advanced UPLC-MS/MS and NMR technologies with automated sample handling, data acquisition, and processing protocols, laboratories can achieve unprecedented levels of throughput, reproducibility, and data quality. These automated workflows have become indispensable tools for addressing the complex challenges of modern drug development, enabling researchers to efficiently characterize drug candidates and advance promising compounds through development pipelines with enhanced confidence in data quality and interpretation.

The continued evolution of these technologies, particularly through improved computational methods and standardized data formats, promises to further accelerate drug discovery while maintaining the rigorous analytical standards required for pharmaceutical development. As these automated workflows become increasingly sophisticated and accessible, they will continue to drive innovation and efficiency across the entire drug development landscape.

Building the Automated Workflow: From Hardware to Data Integration

The integration of robotic platforms with analytical instruments, particularly Ultra-Performance Liquid Chromatography-Mass Spectrometry (UPLC-MS) and Nuclear Magnetic Resonance (NMR) spectroscopy, is transforming modern laboratories into highly efficient, automated systems for reaction monitoring and chemical analysis [36] [37]. This technological synergy addresses growing demands for higher throughput, improved accuracy, and enhanced cost-efficiency in pharmaceutical development and chemical research [36]. Automated workflows now enable seamless sample preparation, analysis, data processing, and reporting with minimal human intervention, significantly accelerating the Design-Make-Test-Analyze (DMTA) cycles critical to drug discovery [38].

The global laboratory automation market, valued at $5.2 billion in 2022, is projected to reach $8.4 billion by 2027, driven largely by adoption in pharmaceutical, biotechnology, and environmental sectors [36]. This growth reflects a fundamental shift toward autonomous laboratories where mobile robotic agents, advanced instrumentation, and intelligent decision-making algorithms create continuous, closed-loop experimentation systems [37] [39]. This application note details the configuration, implementation, and protocols for successfully integrating robotic platforms with UPLC-MS and NMR systems to establish robust automated workflows for reaction monitoring.

System Components and Specifications

A fully integrated automated platform requires coordinated hardware and software components that work in concert to execute analytical workflows. The core system consists of robotic handling systems, analytical instruments, and control software infrastructure.

Robotic Platforms

Robotic systems serve as the physical interface between different analytical modules, transporting samples and performing precise manipulations.

- Mobile Robotic Agents: Free-roaming robots with multipurpose grippers can navigate standard laboratory environments to operate instruments, transfer samples, and perform manual tasks [37]. These systems emulate human researchers without requiring extensive laboratory redesign.

- Fixed Robotic Arms: Stationary robotic systems, such as those integrated into automated synthesizers like the Chemspeed ISynth platform, provide dedicated sample preparation and reformatting capabilities [37] [38].

- Automated Liquid Handlers: Precision robotic systems capable of performing micro-pipetting, solvent preparation, and sample dilution with integrated mass spectrometry feedback [40].

Analytical Instruments

The core analytical technologies for comprehensive reaction monitoring provide orthogonal data for complete chemical characterization.

- UPLC-MS Systems: Provide high-resolution chromatographic separation coupled with mass-based detection for compound identification and quantification [37] [38]. These systems offer superior sensitivity and speed compared to conventional HPLC.

- Benchtop NMR Spectrometers: Compact, cryogen-free instruments like the Magritek Spinsolve Ultra enable automated structural elucidation with high homogeneity magnetic fields for narrow signal linewidths [34] [13]. Their portability allows installation in fume hoods or adjacent to reaction setups.

- Additional Analytical Modules: Systems may incorporate charged aerosol detectors (CAD), diode array detectors (DAD), and supercritical fluid chromatography (SFC) modules for orthogonal separation capabilities [38].

Control Software and Data Systems

Software integration forms the critical link between physical components and enables autonomous operation.

- Laboratory Information Management System (LIMS): Customized platforms like SAPIO LIMS track samples throughout the entire workflow, from submission to final analysis and registration [38].

- Process Control Software: Systems such as LabVision and LabManager provide recipe control, instrument monitoring, and data acquisition capabilities [13].

- Data Processing Tools: Applications like Analytical Studio automate the processing of raw chromatographic and spectral data, accelerating review and decision-making [38].

- Decision-Making Algorithms: Heuristic rule-based systems or AI-driven algorithms (Bayesian optimization, machine learning) process analytical data to determine subsequent experimental steps [37] [13].

Table 1: Core System Components for Automated Robotic-Analytical Integration

| Component Category | Specific Examples | Key Functions | Technical Specifications |

|---|---|---|---|

| Robotic Platforms | Mobile robots with grippers, Chemspeed ISynth, fixed robotic arms | Sample transport, instrument operation, sample preparation | Precision grippers, navigation capabilities, integrated vision systems |

| UPLC-MS Systems | Various commercial UPLC-MS platforms | Chromatographic separation, mass identification, quantification | Sub-2µm particle columns, MRM detection, high pH mobile phases |

| Benchtop NMR | Magritek Spinsolve Ultra, 80 MHz systems | Structural verification, reaction monitoring, quantification | No deuterated solvent requirement, 80 MHz frequency, automated shimming |

| Control Software | LabManager/LabVision, SAPIO LIMS, Analytical Studio | Workflow orchestration, data management, decision-making | Customizable Python scripts, instrument control interfaces |

Integrated Workflow Configuration

The complete integration of robotic platforms with UPLC-MS and NMR instruments establishes an automated workflow for end-to-end reaction monitoring and analysis. The following diagram illustrates the primary components and their interactions:

Workflow Execution

The autonomous operation follows a sequential cycle that mimics expert researcher decision-making:

- Synthesis Initiation: The automated synthesis platform (e.g., Chemspeed ISynth) performs chemical reactions based on an predefined experimental plan or instructions from the decision-making algorithm [37].

- Sample Aliquoting and Reformating: Upon reaction completion, the synthesizer automatically takes aliquots of each reaction mixture and prepares them in appropriate vials or plates for UPLC-MS and NMR analysis [37].

- Robotic Sample Transport: Mobile robots collect the prepared samples and transport them to the respective analytical instruments located elsewhere in the laboratory [37]. This distributed approach allows equipment sharing with human researchers.

- Parallel Analysis: The UPLC-MS and NMR instruments automatically analyze delivered samples:

- UPLC-MS: Typically uses pre-programmed methods with generic gradients to cover a wide polarity range. Data is acquired in multiple reaction monitoring (MRM) mode for targeted analysis or full-scan for untargeted analysis [15] [38].

- Benchtop NMR: Acquires proton (¹H) spectra automatically, often using quantitative NMR (qNMR) protocols with predefined acquisition parameters (4 scans, 6.55 s acquisition time, 15 s repetition time, 90-degree pulse) [13].

- Data Processing and Decision Making: Acquired data is automatically processed and analyzed. A heuristic or AI-driven decision-maker evaluates the results against pass/fail criteria (e.g., detection of expected products, sufficient conversion) to determine subsequent steps, such as scale-up, replication, or new condition exploration [37] [13].

- Iterative Experimentation: The system executes the next set of experiments based on the decision-maker's instructions, creating a closed-loop, autonomous optimization cycle [39].

Experimental Protocols

Protocol: Automated Reaction Monitoring for Compound Synthesis

This protocol describes the automated monitoring of a synthetic reaction using the integrated robotic-UPLC-MS-NMR platform, applicable to reaction optimization and discovery campaigns.

Materials and Reagents

- Reaction substrates and reagents dissolved in appropriate solvents

- LC-MS grade acetonitrile and methanol (e.g., Chromasolv)

- LC-MS grade water (e.g., Milli-Q Integral system)

- Formic acid or ammonium hydroxide for mobile phase pH adjustment

- Ethyl acetate or acetone for dilution

- Deuterated NMR solvents (if required by the NMR system)

Table 2: Research Reagent Solutions for Automated Analysis

| Reagent/Solution | Function/Purpose | Example Application/Notes |

|---|---|---|

| LC-MS Grade ACN/MeOH | UPLC mobile phase organic modifier | Provides sharp peak shape and high sensitivity in MS detection [38] |

| Ammonium Hydroxide (32%) | Mobile phase pH modifier for basic compounds | Used at high pH (e.g., 10) for improved chromatographic separation [38] |

| Formic Acid (FA) | Mobile phase pH modifier for acidic compounds | Typical concentration 0.1% in mobile phase for positive ion mode MS [38] |

| Ethyl Acetate | Solvent for reaction mixture dilution | Compatible with UPLC-MS and NMR analysis; used in Knoevenagel condensation optimization [13] |

| Dichloromethane in Acetone | Post-reaction dilution solvent | Prevents product precipitation prior to NMR analysis in flow reactor setups [13] |

Equipment and Instrumentation

- Chemspeed ISynth automated synthesizer or equivalent

- Mobile robotic agent with multipurpose gripper

- UPLC-MS system with appropriate stationary phases

- Benchtop NMR spectrometer (e.g., Magritek Spinsolve Ultra)

- Laboratory control software (e.g., LabManager/LabVision)

- Centralized data system running decision-making algorithms

Procedure

System Initialization

- Power on all instruments and initialize control software.

- Verify mobile robot navigation paths and ensure clear access to all instruments.

- Perform quality control checks on UPLC-MS and NMR systems using standard reference materials.

- In the control software, load the experimental plan detailing reaction compositions and conditions.

Reaction Setup and Execution

- Command the automated synthesizer to prepare reaction mixtures according to the experimental plan in designated vials or microtiter plates.

- Program the synthesizer to maintain specified reaction conditions (temperature, stirring, time).

- Upon reaction completion, the synthesizer automatically aliquots each reaction mixture into separate UPLC-MS vials and NMR tubes.

Automated Sample Analysis

- The mobile robot collects UPLC-MS vials and transports them to the autosampler of the UPLC-MS system.

- The UPLC-MS system executes analysis using pre-programmed methods. A typical UPLC method uses:

- Column: C18 or HILIC stationary phase

- Gradient: 5-95% organic modifier over 3-10 minutes

- Detection: MS in MRM or full-scan mode

- Simultaneously, the robot delivers NMR tubes to the benchtop NMR spectrometer.

- The NMR system acquires ¹H spectra automatically using a standard qNMR method with solvent suppression if needed.

Data Processing and Decision Cycle

- Raw UPLC-MS and NMR data are automatically transferred to the central data system.

- Software algorithms process the data: UPLC-MS data is analyzed for peak identification and quantification, while NMR spectra are evaluated for reaction-specific signatures.

- The heuristic decision-maker applies pre-defined pass/fail criteria to the combined data set:

- UPLC-MS Criteria: Detection of expected mass ions, acceptable chromatographic peak shape.

- NMR Criteria: Disappearance of starting material signals, appearance of product signals, sufficient signal-to-noise ratio.

- Reactions passing both UPLC-MS and NMR criteria are selected for further investigation (scale-up, diversification).

- The decision-maker sends new experimental instructions to the automated synthesizer for the next iteration.

System Shutdown

- After experiment completion, command the system to run cleaning cycles for fluidic paths.

- Return all robotic agents to their docking stations.

- Archive all experimental data and results in the LIMS.

Protocol: Self-Optimization of Reaction Conditions in Flow

This protocol details the configuration for autonomous real-time optimization of reaction conditions in a flow reactor using inline NMR monitoring and Bayesian optimization algorithms, based on the setup by Magritek and HiTec Zang [13].

Materials and Reagents

- Reaction substrates (e.g., salicylaldehyde and ethyl acetoacetate for Knoevenagel condensation)

- Catalyst (e.g., piperidine)

- Anhydrous solvents (e.g., ethyl acetate)

- Dilution solvent (e.g., acetone with internal standard)

Equipment and Instrumentation

- Modular flow reactor system (e.g., Ehrfeld Micro Reaction System)

- Syringe pumps (e.g., SyrDos) for reagent delivery

- Benchtop NMR spectrometer (e.g., Spinsolve Ultra) with flow cell

- Process control system (e.g., LabManager/LabVision)

- Computer running Bayesian optimization algorithm

Procedure

- System Configuration

- Set up the flow reactor with integrated NMR flow cell as illustrated in the diagram below.

- Connect the control system to regulate temperature, pressure, and pump flow rates.

- Configure the NMR spectrometer for automated, triggered acquisition using the external control mode.

- Optimization Workflow

- Prepare reactant solutions and load them into the syringe pumps.

- In the control software, define the optimization goal (e.g., maximize yield) and parameter constraints (flow rate ranges).

- Initiate the autonomous optimization cycle:

- The Bayesian algorithm proposes initial flow rate conditions.

- The system achieves steady state at these conditions.

- The NMR spectrometer automatically acquires and analyzes spectra using qNMR protocols.

- Yield is calculated based on integral ratios of reactant and product signals.

- The yield value is fed back to the optimization algorithm.

- The algorithm calculates and sets new flow rate conditions for the next iteration.

- The system continues this cycle until convergence to optimal conditions or a maximum number of iterations.

Data Management and Analysis

Effective data management is crucial for successful automated workflows. The integration of Laboratory Information Management Systems (LIMS) ensures comprehensive sample tracking and data integrity throughout the process [38].

- Centralized Data Repository: All analytical data (UPLC-MS chromatograms, NMR spectra) and experimental metadata are automatically stored in a centralized database with standardized formats to ensure Findability, Accessibility, Interoperability, and Reusability (FAIR principles) [38] [40].

- Automated Data Processing: Software tools like Analytical Studio automatically process raw chromatographic data, performing peak integration, compound identification, and purity assessment [38]. For NMR data, Python scripts or machine learning models can automate spectral analysis and interpretation [34] [41].

- Decision-Making Algorithms: Heuristic rule-based systems apply expert-defined criteria to analytical results, while AI-driven approaches use machine learning or Bayesian optimization to guide experimental progression [37] [13]. These algorithms combine orthogonal data from UPLC-MS and NMR to make robust decisions on subsequent experimental steps.

Troubleshooting and Technical Considerations

Successful implementation requires addressing several technical challenges:

- Instrument Interoperability: Standardize communication protocols and data formats across different manufacturers' equipment using standards such as SiLA (Standardization in Lab Automation) [40].

- Spatial and Temporal Biases: In microtiter plate-based systems, account for edge effects and ensure consistent heating/lighting across all wells [42].

- Data Quality Validation: Implement automated quality control checks for both UPLC-MS (peak shape, retention time stability) and NMR (linewidth, signal-to-noise ratio) data [38].