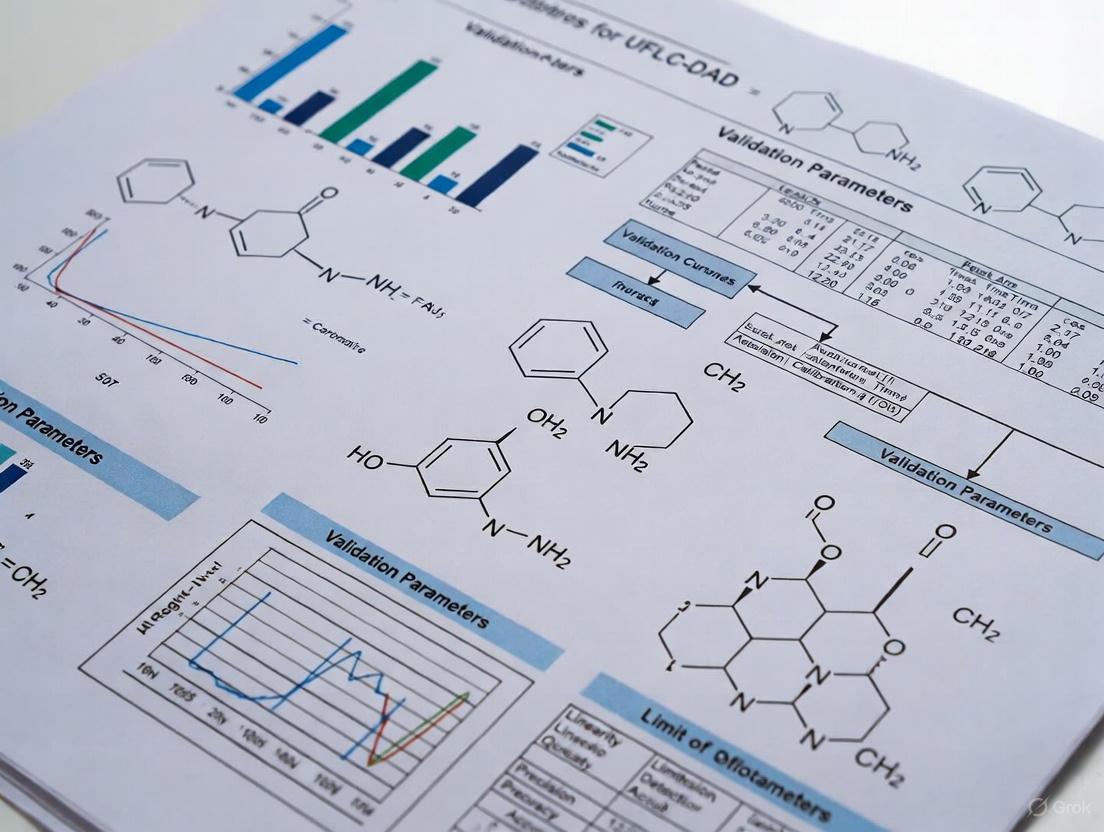

Comprehensive Validation of UFLC-DAD Methods in Pharmaceutical Analysis: Parameters, Protocols, and Best Practices

This article provides a comprehensive guide to the validation of Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) methods for pharmaceutical analysis.

Comprehensive Validation of UFLC-DAD Methods in Pharmaceutical Analysis: Parameters, Protocols, and Best Practices

Abstract

This article provides a comprehensive guide to the validation of Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) methods for pharmaceutical analysis. Tailored for researchers, scientists, and drug development professionals, it covers foundational principles, methodological applications, troubleshooting strategies, and comparative assessments against other techniques. The content aligns with ICH guidelines and emphasizes practical implementation for ensuring reliability, accuracy, and reproducibility in quality control and drug development processes. Future directions and implications for biomedical research are also discussed.

UFLC-DAD Fundamentals: Principles and Regulatory Framework for Pharmaceutical Applications

Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) represents a significant advancement in analytical separation technology. It offers enhanced speed, superior resolution, and greater efficiency compared to conventional techniques like High-Performance Liquid Chromatography (HPLC) and spectrophotometry, making it particularly valuable for pharmaceutical analysis [1] [2].

Direct Performance Comparison: UFLC-DAD vs. Alternative Techniques

The table below summarizes a comparative analysis of UFLC-DAD against conventional HPLC and UV spectrophotometry, based on experimental data from pharmaceutical and natural product analysis.

| Analytical Technique | Analysis Time | Key Performance Advantages | Limitations / Drawbacks |

|---|---|---|---|

| UFLC-DAD | ~40 minutes [2] | Shorter analysis time, increased peak capacity, lower consumption of samples and solvents, high sensitivity and selectivity [1] [2]. | Higher equipment cost and complexity than spectrophotometry [1]. |

| Conventional HPLC | ~75 minutes [2] | Widely established, high selectivity for complex mixtures. | Longer analysis time and higher solvent consumption compared to UFLC [2]. |

| UV Spectrophotometry | N/A (Rapid measurement) | Economical, simplified operation, good precision, and speed [1]. | Limited specificity with overlapping bands, requires larger sample amounts, cannot analyze higher concentrations (e.g., 100 mg tablets) [1]. |

Key Comparative Insights:

- Speed and Solvent Use: A study on fingerprint analysis of Ligusticum chuanxiong demonstrated that UFLC-DAD could reduce the analysis time from 75 minutes on conventional HPLC to 40 minutes, while also consuming less solvent [2].

- Specificity and Application Range: While spectrophotometry is cost-effective, it faces limitations in specificity when analyzing complex samples. UFLC-DAD does not suffer from these limitations and can successfully quantify active components in both 50 mg and 100 mg pharmaceutical tablets, whereas the spectrophotometric method was limited to the 50 mg tablets [1].

Validation Parameters for UFLC-DAD in Pharmaceutical Analysis

For any analytical method to be deemed reliable for pharmaceutical research, it must undergo a rigorous validation process. The following parameters are crucial for UFLC-DAD, as demonstrated in the analysis of metoprolol tartrate (MET) [1]:

- Specificity/Selectivity: The method must effectively identify and discriminate the analyte of interest from other compounds in the sample [1].

- Linearity and Dynamic Range: The method should demonstrate a directly proportional response to the concentration of the analyte across a specified range [1].

- Sensitivity: This is defined by the Limit of Detection (LOD) and Limit of Quantification (LOQ), which are the lowest amounts of analyte that can be detected and reliably quantified, respectively [1].

- Accuracy: This parameter indicates the closeness of the measured value to the true value of the sample [1].

- Precision: This refers to the closeness of agreement between a series of measurements obtained from multiple sampling of the same homogeneous sample [1].

- Robustness: A measure of the method's capacity to remain unaffected by small, deliberate variations in method parameters [1].

Statistical tools like Analysis of Variance (ANOVA) and Student's t-test are employed to validate that there is no significant difference between the results obtained by the validated UFLC-DAD method and the true value, confirming its suitability for routine analysis [1].

Detailed Experimental Protocol for Pharmaceutical Analysis

The following workflow, based on the study of metoprolol in tablets, outlines a typical protocol for method development and validation using UFLC-DAD [1].

Experimental Workflow for UFLC-DAD Method Validation

Key Steps in the Protocol:

- Sample and Standard Preparation: A standard of the active pharmaceutical ingredient (API), such as MET (≥98%), is accurately weighed and dissolved in an appropriate solvent, typically ultrapure water (UPW). Sample solutions are prepared from commercial tablets by extracting the API. All solutions are protected from light to prevent degradation [1].

- UFLC-DAD Instrumental Optimization: Before validation, the chromatographic conditions are optimized. This includes selecting the composition of the mobile phase, adjusting the flow rate, setting the column temperature, and defining the detection wavelengths on the DAD. The advent of UFLC results in shorter analysis times and increased peak capacity [1].

- Execution of Validation Parameters: The method is systematically tested for all parameters mentioned in the previous section (specificity, linearity, LOD/LOQ, accuracy, precision, robustness) [1].

- Statistical Analysis and Greenness Assessment: The collected data is analyzed using statistical tools like ANOVA to confirm the method's reliability. Furthermore, the method's environmental impact can be evaluated using metrics like the Analytical GREEnness (AGREE) approach [1].

The Scientist's Toolkit: Essential Research Reagents and Materials

The table below lists key materials and reagents required for developing and validating a UFLC-DAD method for pharmaceutical analysis.

| Item Name | Function / Role in Analysis | Specific Example from Research |

|---|---|---|

| Analytical Standard | Provides a pure reference for identifying and quantifying the target analyte. | Metoprolol tartrate (≥98%, Sigma-Aldrich) [1]. |

| Ultrapure Water (UPW) | Serves as a key solvent for preparing standard and sample solutions. | Used to dissolve MET standard and for extraction from tablets [1]. |

| Chromatographic Solvents | Form the mobile phase to elute compounds through the column. | Acetonitrile and methanol, often acidified with acetic acid [3]. |

| UFLC-DAD System | The core instrument for separation (column), detection (DAD), and data analysis. | Ultra-Fast Liquid Chromatography system with Diode Array Detector [1]. |

Analytical Performance Data from Comparative Studies

The validation of a method provides concrete, quantitative data on its performance. The following table compiles key metrics from the validation of a UFLC-DAD method for metoprolol and, for broader context, an HPLC-DAD method for quercetin, illustrating typical validation outcomes [1] [3].

| Validation Parameter | Experimental Result (UFLC-DAD for MET) [1] | Experimental Result (HPLC-DAD for Quercetin) [3] |

|---|---|---|

| Linearity (R²) | Successfully validated [1] | R² > 0.995 [3] |

| Precision (Repeatability) | Successfully validated [1] | RSD ≤ 6.74% [3] |

| Accuracy | Successfully validated [1] | 88.6% - 110.7% [3] |

| Limit of Detection (LOD) | Successfully validated [1] | 0.046 µg/mL [3] |

| Limit of Quantification (LOQ) | Successfully validated [1] | 0.14 µg/mL [3] |

The data confirms that UFLC-DAD is a robust, precise, and accurate technique, fully validated for the rigorous demands of pharmaceutical quality control and research.

In the highly regulated field of pharmaceutical analysis, the specificity and selectivity of an analytical method are paramount. Specificity is the ability to assess unequivocally the analyte in the presence of components that may be expected to be present, while selectivity refers to the ability of the method to distinguish the analyte from other substances in a complex mixture. For researchers and drug development professionals, Diode Array Detection (DAD) coupled with Ultra-Fast Liquid Chromatography (UFLC) provides a powerful tool to meet these critical validation parameters. Unlike single-wavelength detectors, a DAD simultaneously captures absorbance data across a broad spectrum of wavelengths, providing a multi-dimensional dataset that is indispensable for confirming analyte identity, assessing peak purity, and ensuring the reliability of quantitative results.

The Technological Edge of DAD

Fundamental Principles and Capabilities

A Diode Array Detector operates on a fundamental principle different from a standard variable wavelength detector (VWD). While a VWD uses a monochromator to select a single wavelength to pass through the flow cell, a DAD passes polychromatic light through the flow cell and then disperses the transmitted light onto an array of photodiodes [4]. This allows the instrument to capture the full UV-Vis spectrum (typically 190–600 nm or more) for every data point collected during the chromatographic run.

The key capabilities that flow from this principle are:

- Simultaneous Multi-Wavelength Monitoring: A method can be set to quantify analytes at their respective maximum absorbance wavelengths (λmax) for superior sensitivity, while also collecting data at other wavelengths for confirmatory purposes [5] [6].

- Spectral Acquisition for Peak Identification: The continuous capture of full spectra creates a unique "fingerprint" for each analyte, which can be used for identification by comparing against a library of reference spectra [7].

- Peak Purity Assessment: By comparing spectra extracted from different segments of a chromatographic peak (up-slope, apex, down-slope), the software can determine if the peak originates from a single, pure compound or if it is co-eluting with an impurity [4].

The following diagram illustrates the core workflow of a DAD and how its data output directly enhances specificity and selectivity.

Comparative Analysis: DAD vs. Single-Wavelength Detection

The superiority of DAD in method specificity and selectivity becomes clear when directly compared to single-wavelength UV detection. The table below summarizes the critical differences.

Table 1: Key Feature Comparison between Diode Array and Single-Wavelength Detectors

| Feature | Diode Array Detector (DAD) | Single-Wavelength Detector |

|---|---|---|

| Spectral Data | Full UV-Vis spectrum for every point in the chromatogram [4]. | Absorbance at only one or a few pre-selected wavelengths. |

| Peak Purity Analysis | Yes, via automated spectral comparison across the peak [4]. | No, co-eluting peaks with similar retention times may go undetected. |

| Analyte Identification | High, via library spectrum matching [7]. | Low, reliant on retention time alone. |

| Method Development | Post-run wavelength optimization without re-injection. | Requires multiple injections to determine optimal wavelength. |

| Specificity & Selectivity | High, multi-dimensional confirmation. | Moderate, limited to retention time and single wavelength. |

Experimental Validation and Supporting Data

The practical benefits of UFLC-DAD are demonstrated in its widespread application across pharmaceutical development, from assay determination to dissolution testing.

Case Study: Multi-Analyte Formulation Analysis

A validated UFLC-DAD method for the simultaneous quantification of three antihypertensive drugs—telmisartan, chlorthalidone, and amlodipine—in a fixed-dose combination tablet showcases the detector's critical role [5]. The researchers selected different wavelengths for quantifying each drug based on their respective maximum absorbance, optimizing sensitivity. The specificity of the method was confirmed by the clear baseline separation of all three analytes and the absence of interference from excipients. The identity of each peak was verified by its retention time and UV spectrum, providing a high degree of confidence in the results for quality control purposes [5].

Table 2: Experimental Data from the Simultaneous Analysis of an Antihypertensive Formulation [5]

| Analyte | Selected Wavelength (nm) | Linearity Range (μg/mL) | Limit of Quantification (μg/mL) | Application |

|---|---|---|---|---|

| Telmisartan | 240 | 1.0–140.0 | 0.061 | Tablet assay & dissolution |

| Chlorthalidone | 240 | 1.0–100.0 | 0.177 | Tablet assay & dissolution |

| Amlodipine | 240 | 1.0–100.0 | 0.313 | Tablet assay & dissolution |

Case Study: Specificity in Complex Matrices

The need for selectivity is even more critical in bioanalysis. An HPLC-DAD method for quantifying thiopurine metabolites (TGN and MMPN) in red blood cells from pediatric patients exemplifies this [6]. The method validated per ICH guidelines demonstrated specificity by resolving the analytes from endogenous compounds in the complex biological matrix. Detection and quantification were performed at 304 nm and 341 nm for MMPN and TGN, respectively, with spectral confirmation ensuring the identity of the target metabolites in patient samples [6]. This application underscores how DAD provides the necessary confidence for therapeutic drug monitoring.

The Scientist's Toolkit: Essential Reagents and Materials

The development and validation of a robust UFLC-DAD method require specific, high-quality materials. The following table lists key reagents and their functions based on the protocols cited in this article.

Table 3: Key Research Reagent Solutions for UFLC-DAD Method Development

| Reagent / Material | Function / Purpose | Example from Literature |

|---|---|---|

| HPLC-Grade Solvents | Mobile phase components; ensures low UV background noise and reproducible separations. | Acetonitrile, Methanol, Water [5] [6]. |

| Buffer Salts | Modifies mobile phase pH to control ionization, retention, and peak shape. | Potassium dihydrogen phosphate [6]. |

| Analytical Standards | Used for calibration, identification, and quantification; certified purity is essential. | Metoprolol tartrate (≥98%) [1], Telmisartan (99.58%) [5]. |

| Derivatization Reagents | Enhances detectability or separation of compounds lacking chromophores. | 9-fluorenylmethyl chloroformate (Fmoc-Cl) for amino acids [8]. |

| Column Stationary Phases | Medium for chromatographic separation (e.g., C18); selected based on analyte properties. | Inertsil C18 column [5], InfinityLab Poroshell 120 [8]. |

In the context of pharmaceutical analysis, where method validation is non-negotiable, Diode Array Detection provides an unparalleled layer of confidence. Its ability to deliver simultaneous quantitative data and qualitative spectral information directly addresses the core validation parameters of specificity and selectivity. By enabling peak purity assessment, spectral confirmation of analyte identity, and post-acquisition method optimization, UFLC-DAD moves beyond mere quantification to comprehensive characterization. For researchers and drug development professionals, this technology is not merely an alternative but a fundamental tool for ensuring the accuracy, reliability, and regulatory compliance of analytical methods throughout the drug development lifecycle.

The International Council for Harmonisation (ICH) Q2(R2) and FDA guidelines form the cornerstone of analytical method validation for pharmaceuticals, ensuring the reliability, accuracy, and consistency of data for drug quality control. The recent adoption of the finalized ICH Q2(R2) guideline in March 2024, alongside the new ICH Q14 guideline on analytical procedure development, marks a significant evolution from a prescriptive, "check-the-box" approach to a more scientific, risk-based, and lifecycle-oriented model [9] [10] [11]. This modernized framework, which the U.S. Food and Drug Administration (FDA) has implemented, provides a harmonized global standard that is crucial for regulatory submissions like New Drug Applications (NDAs) and Abbreviated New Drug Applications (ANDAs) [10]. For researchers employing techniques like UFLC-DAD, understanding these guidelines is paramount for demonstrating that an analytical procedure is fit for its intended purpose, from development through post-approval changes [11].

This guide objectively compares the performance of different analytical techniques within this updated regulatory context, providing experimental data and methodologies to support robust pharmaceutical analysis.

Core Validation Parameters: ICH Q2(R2) and FDA Requirements

ICH Q2(R2) outlines the fundamental validation characteristics required to prove an analytical method's suitability [12] [10]. The parameters to be tested depend on the type of method (e.g., identification, quantitative impurity test, or assay). The table below summarizes the key parameters and their definitions, which are universally applied to techniques like UFLC-DAD and spectrophotometry.

Table 1: Core Analytical Method Validation Parameters as per ICH Q2(R2)

| Validation Parameter | Definition and Regulatory Requirement |

|---|---|

| Accuracy | The closeness of agreement between the test result and the true or accepted reference value. It is typically established by spiking a placebo with a known amount of analyte or by using a reference standard [10] [13]. |

| Precision | The degree of agreement among individual test results from repeated applications of the method. This includes repeatability (intra-assay), intermediate precision (inter-day, inter-analyst), and reproducibility (inter-laboratory) [10] [13]. |

| Specificity | The ability to assess the analyte unequivocally in the presence of other components like impurities, degradants, or excipients. This proves that the method can distinguish the analyte from everything else that might be in the sample [10] [13]. |

| Linearity | The ability of the method to obtain test results that are directly proportional to the concentration of the analyte within a given range [10] [13]. |

| Range | The interval between the upper and lower concentrations of the analyte for which the method has demonstrated suitable linearity, accuracy, and precision [10]. |

| Limit of Detection (LOD) | The lowest amount of analyte in a sample that can be detected, but not necessarily quantified, under the stated experimental conditions [10] [13]. |

| Limit of Quantitation (LOQ) | The lowest amount of analyte in a sample that can be quantitatively determined with acceptable accuracy and precision [10] [13]. |

| Robustness | A measure of the method's capacity to remain unaffected by small, deliberate variations in method parameters (e.g., pH, mobile phase composition, flow rate). It is now a more formalized part of the development and validation process under Q2(R2) and Q14 [10]. |

A pivotal concept introduced in the companion guideline ICH Q14 is the Analytical Target Profile (ATP). The ATP is a prospective summary of the method's intended purpose and its required performance criteria [10]. Defining the ATP at the outset of method development ensures a science- and risk-based approach, guiding the selection of validation parameters and acceptance criteria to ensure the method is fit-for-purpose from the very beginning [10].

Comparative Analysis of UFLC-DAD and Spectrophotometry

A 2024 study directly compared Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) and UV spectrophotometry for quantifying metoprolol tartrate (MET) in commercial tablets, offering a clear performance comparison under ICH validation principles [1].

Table 2: Experimental Performance Comparison: UFLC-DAD vs. Spectrophotometry for MET Analysis

| Validation Parameter | UFLC-DAD Method Performance | UV Spectrophotometry Method Performance |

|---|---|---|

| Application Scope | Successfully validated for 50 mg and 100 mg MET tablets [1]. | Applied only to 50 mg tablets due to concentration limitations of the technique [1]. |

| Selectivity/Specificity | High selectivity, effectively discriminating the analyte from other tablet components [1]. | Lower selectivity; susceptible to interference from other compounds that may absorb at the same wavelength [1]. |

| Sensitivity | Higher sensitivity, suitable for detecting and quantifying lower analyte levels [1]. | Lower sensitivity, limiting its use for lower-dose formulations [1]. |

| Sample & Solvent Consumption | Lower sample volume required; however, the overall process may use more solvents [1]. | Requires larger sample amounts for analysis [1]. |

| Cost & Operational Complexity | Higher equipment cost, maintenance, and operational complexity [1]. | Substantially more cost-effective and simpler to operate [1]. |

| Environmental Impact (AGREE Metric) | Environmentally friendly process [1]. | More environmentally friendly overall, with a better greenness score [1]. |

| Statistical Conclusion (ANOVA, t-test) | No significant difference in the determined concentrations of MET between the two validated methods, confirming both are suitable for routine analysis [1]. | No significant difference from UFLC-DAD results for the 50 mg tablets, making it a precise and accurate alternative for this specific application [1]. |

Detailed Experimental Protocol for Method Comparison

The following workflow illustrates the key experimental steps undertaken in the comparative validation of UFLC-DAD and spectrophotometry for MET analysis [1]:

Key Experimental Steps [1]:

- Sample Preparation: Metoprolol tartrate (MET) reference standard (≥98%, Sigma-Aldrich) was used. A basic MET solution was prepared by dissolving an appropriate mass in ultrapure water. Standard solutions for calibration curves were similarly prepared. All solutions were protected from light.

- UFLC-DAD Analysis: The UFLC-DAD method was optimized prior to validation. Specific chromatographic conditions (column, mobile phase, etc.) were developed to achieve separation and detection.

- Spectrophotometry Analysis: Absorbance was recorded at the maximum absorption wavelength for MET, λ = 223 nm.

- Validation: Both methods were assessed for specificity/selectivity, sensitivity, linearity, range, LOD, LOQ, accuracy, precision, and robustness as per ICH requirements.

- Statistical Analysis: Analysis of Variance (ANOVA) and Student's t-test at a 95% confidence level were performed using the DataExplorer Online tool to determine if there was a significant difference between the results from the two methods.

- Greenness Assessment: The environmental impact of each method was evaluated using the Analytical GREEnness (AGREE) metric approach.

Essential Research Reagent Solutions

The successful development and validation of analytical methods rely on specific, high-quality reagents and materials. The following table details key components used in the cited studies.

Table 3: Essential Research Reagents and Materials for Analytical Method Development

| Reagent / Material | Function and Application in Analysis |

|---|---|

| Metoprolol Tartrate (MET) Standard | A certified reference standard used for accurate method calibration, quantification, and determination of accuracy [1]. |

| 9-Fluorenylmethyl Chloroformate (Fmoc-Cl) | A derivatizing agent used in HPLC to react with amino acids, creating stable derivatives that can be detected with UV or fluorescence detectors [8]. |

| Ultrapure Water (UPW) | The solvent of choice for preparing mobile phases, standard solutions, and samples to prevent interference from impurities [1]. |

| Chromatography Columns (e.g., InfinityLab Poroshell, silica-based phenyl) | The stationary phase where chemical separation occurs. The selection of column chemistry (C18, phenyl, etc.) is critical for achieving resolution and selectivity [14] [8]. |

| HPLC-Grade Solvents (Acetonitrile, Methanol) | High-purity solvents used as components of the mobile phase to ensure low UV background noise and reproducible chromatographic performance [1] [14]. |

The simultaneous application of ICH Q2(R2) for validation and ICH Q14 for development represents the current regulatory standard, emphasizing a holistic lifecycle management approach [10] [15]. For pharmaceutical researchers, this means:

- Strategic Method Selection: The choice between sophisticated techniques like UFLC-DAD and simpler methods like spectrophotometry should be driven by the ATP and a risk-based assessment. As demonstrated, spectrophotometry can be a valid, cost-effective, and greener alternative for specific, straightforward assays like high-dose API quantification, provided it is fully validated [1].

- Focus on Scientific Rationale: Regulatory flexibility in post-approval changes is more achievable when methods are developed under the enhanced approach described in ICH Q14, which requires a deeper understanding of the method's operational boundaries and robustness [10].

- Commitment to Continuous Validation: Method validation is not a one-time event but a continuous process that reinforces data integrity, regulatory compliance, and ultimately, patient safety [13].

By embracing these modernized guidelines, scientists and drug development professionals can ensure their analytical methods are not only compliant but also robust, efficient, and sustainable throughout the product lifecycle.

In the highly regulated pharmaceutical industry, validation is a formal, systematic process defined as the "collection and evaluation of data, from the process design stage through commercial production, which establishes scientific evidence that a process is capable of consistently delivering a quality product" [16]. Unlike verification, which tests individual units, validation provides assurance that the entire manufacturing process—including equipment, procedures, and personnel—will reliably produce products meeting predetermined quality attributes batch after batch. This is particularly critical when direct testing of every unit is impractical or impossible, as is often the case with complex pharmaceuticals, biologics, and gene therapies [16].

For researchers and scientists developing analytical methods, validation demonstrates that an analytical procedure is suitably optimized and reliable for its intended purpose, ensuring the identity, potency, purity, and performance of drug products [1]. In the context of Ultra-Fast Liquid Chromatography coupled with Diode Array Detection (UFLC-DAD), rigorous validation provides the foundation for generating trustworthy data throughout drug development and quality control.

Core Principles and Regulatory Mandate of Validation

Pharmaceutical validation is not merely a best practice but a legal enforceable requirement under 21 CFR Parts 210 and 211 [16]. Regulatory bodies worldwide mandate validation to protect consumer safety by ensuring that every drug product possesses the identity, strength, quality, and purity it claims to have. The consequences of validation missteps can be severe, including regulatory citations, failed audits, costly corrective actions, and most critically, the distribution of adulterated products that risk patient health [16].

Effective implementation of pharmaceutical validation rests on six core principles [16]:

- Understanding Relevant Regulatory Guidelines: Adherence to FDA regulations (21 CFR) and international standards (ICH) is fundamental.

- Building a Cross-Functional Team: Validation requires collaboration across operations, purchasing, testing, and other departments.

- Executing a Well-Documented Validation Plan: A detailed Validation Master Plan (VMP) based on Installation (IQ), Operational (OQ), and Performance (PQ) Qualification is essential.

- Identifying Organizational Gaps: Proactively addressing resource, knowledge, or procedural shortcomings before validation begins.

- Conducting Validation Throughout the Product Lifecycle: Validation is not a one-time event but applies from process design to commercial production.

- Regularly Revisiting and Updating Processes: Validation documentation and processes must be maintained and updated as changes occur.

The following workflow outlines the key stages of the analytical method validation process in pharmaceutical quality control:

Validation Parameters for UFLC-DAD in Pharmaceutical Analysis

Method validation for UFLC-DAD must assess multiple performance parameters to prove the method is suitable for its intended use. The following table summarizes the core validation parameters, their definitions, and typical acceptance criteria as demonstrated in pharmaceutical applications [1] [17].

Table 1: Key Validation Parameters for UFLC-DAD Methods in Pharmaceutical Analysis

| Validation Parameter | Definition and Purpose | Exemplary Application & Acceptance Criteria |

|---|---|---|

| Specificity/Selectivity | Ability to measure analyte accurately in the presence of potential interferences (excipients, impurities). | Confirmed by no interference from tablet excipients at the retention time of metoprolol tartrate [1]. |

| Linearity and Range | The method's ability to produce results directly proportional to analyte concentration within a given range. | Linear calibration curves for metoprolol with R² > 0.999 [1]. Linear for guanylhydrazones LQM10, LQM14, LQM17 with R² > 0.999 [17]. |

| Accuracy | Closeness of measured value to the true value, often assessed as % recovery of spiked analyte. | Recovery of metoprolol from tablets ranged from 98.7% to 101.5% [1]. Recovery of guanylhydrazones between 99-102% [17]. |

| Precision | Degree of agreement among individual test results (Repeatability and Intermediate Precision). | Intra-day and inter-day precision for metoprolol RSD < 2.0% [1]. Intra-day precision for guanylhydrazones RSD 0.53-2.00% [17]. |

| Limit of Detection (LOD) | Lowest amount of analyte that can be detected but not necessarily quantified. | LOD for carbonyl compounds in soybean oil: 0.03 to 0.1 μg/mL [18] [19]. |

| Limit of Quantification (LOQ) | Lowest amount of analyte that can be quantified with acceptable precision and accuracy. | LOQ for carbonyl compounds: 0.2 μg/mL for all compounds [18] [19]. LOQ for polyphenols in applewood: 0.0225–0.3572 mg/L [20]. |

| Robustness | Capacity to remain unaffected by small, deliberate variations in method parameters (e.g., flow rate, pH). | Robustness demonstrated for metoprolol method against variations in flow rate (±0.05 mL/min) and mobile phase pH (±0.05) [1]. |

Comparative Performance: UFLC-DAD vs. Alternative Analytical Techniques

Selecting the appropriate analytical technique requires a clear understanding of the relative strengths and limitations of available technologies. UFLC-DAD is often compared with traditional HPLC, advanced UHPLC, and simpler spectrophotometric methods.

Table 2: Comparison of UFLC-DAD with Alternative Analytical Techniques

| Technique | Key Advantages | Inherent Limitations | Ideal Application Context |

|---|---|---|---|

| UFLC-DAD | Faster analysis and higher peak capacity than HPLC; lower solvent consumption; DAD provides spectral confirmation and peak purity assessment [1] [21]. | Higher equipment cost than spectrophotometry; less sensitive and selective than MS-detection [22]. | Routine quality control of active ingredients in pharmaceuticals where multi-wavelength detection and peak identity confirmation are valuable [1]. |

| UHPLC-DAD | Highest efficiency: Uses sub-2μm particles for superior speed and resolution; maximum solvent reduction [17] [20]. | Requires instrumentation capable of withstanding very high pressures; potentially higher operational costs. | High-throughput analysis of complex mixtures, e.g., 38 polyphenols in 21 minutes [20]. |

| Spectrophotometry | Low cost, simple operation, high precision and speed [1]. | Lacks selectivity for mixtures (overlapping bands); difficult quantitative analysis with interferences [1]. | Analysis of single-component samples or for applications where the cost is a primary driver and selectivity is not a concern [1]. |

| LC-MS | High sensitivity and selectivity; superior for identifying unknown compounds and structural elucidation [23]. | Very high cost; complex operation; susceptible to matrix effects that can suppress/enhance ionization [22]. | Bioanalysis, metabolite profiling, and identification of degradation products where ultimate sensitivity and specificity are required. |

The following diagram illustrates the logical decision process for selecting an appropriate analytical technique based on method requirements:

Experimental Protocols and Data Comparison

Case Study: Validation of a UFLC-DAD Method for Metoprolol Tartrate

A comparative study developed and validated methods for analyzing metoprolol tartrate (MET) in commercial tablets using both UFLC-DAD and spectrophotometry [1].

- Chromatographic Conditions: A UFLC system with a DAD detector was used. The stationary phase was a C18 column, and the mobile phase consisted of a mixture of acetate buffer (pH 4.0) and methanol (45:55, v/v) at a flow rate of 0.5 mL/min. Detection was performed at 223 nm.

- Sample Preparation: MET was extracted from tablets using ultrapure water. Solutions were protected from light and stored in a dark place.

- Validation Results: The UFLC-DAD method was successfully validated for 50 mg and 100 mg tablets. It demonstrated high specificity with no interference from excipients, excellent linearity (R² > 0.999), and high accuracy with recoveries between 98.7% and 101.5%. The precision was also high, with RSD values below 2.0% for both intra-day and inter-day variations [1].

- Comparative Outcome: While the spectrophotometric method was adequate for 50 mg tablets, the UFLC-DAD method provided superior selectivity and was applicable to both dosage strengths. Statistical analysis (ANOVA, t-test) confirmed the reliability of the UFLC-DAD method for routine analysis [1].

Case Study: UHPLC-DAD for Polyphenols in Applewood

While not a pharmaceutical product, a recent study on applewood polyphenols showcases the high-throughput capabilities of modern liquid chromatography with DAD [20].

- Method Performance: The validated UHPLC-DAD method simultaneously quantified 38 polyphenols in just 21 minutes. It demonstrated excellent linearity (R² > 0.999 for all analytes), high sensitivity (LOQs as low as 0.0225 mg/L), and excellent accuracy (recovery 95-104%) and precision (RSD < 5%) [20].

- Context for Pharma: This demonstrates the potential of UHPLC-DAD for complex analyses, such as profiling plant-derived pharmaceuticals or excipients, where multiple active or interfering compounds must be monitored simultaneously with high efficiency and low solvent consumption.

The Scientist's Toolkit: Essential Reagents and Materials

Successful development and validation of a UFLC-DAD method require specific, high-quality materials and reagents.

Table 3: Essential Research Reagent Solutions for UFLC-DAD Method Validation

| Reagent / Material | Function and Specification | Pharmaceutical Analysis Example |

|---|---|---|

| Ultra-Pure Water (UPW) | Solvent for mobile phase and sample preparation; must be free of interfering ions and organics. | Used as the solvent for preparing metoprolol standard and sample solutions [1]. |

| HPLC-Grade Solvents | Components of the mobile phase (e.g., acetonitrile, methanol); high purity is critical to reduce baseline noise and ghost peaks. | Methanol and water were used in the mobile phase for metoprolol analysis [1]. Acetonitrile was optimized as the extraction solvent for carbonyl compounds from oil [18]. |

| Buffer Salts | Modify mobile phase pH to control analyte ionization, retention, and peak shape (e.g., acetate, phosphate). | Acetate buffer (pH 4.0) was used in the mobile phase for metoprolol separation [1]. Acetic acid was added to the mobile phase for guanylhydrazone analysis to improve peak symmetry [17]. |

| Reference Standards | Highly purified analyte used to prepare calibration standards for quantification, accuracy, and linearity studies. | Metoprolol tartrate (≥98%, Sigma-Aldrich) was used as the primary standard [1]. Certified carbonyl compounds were used as standards for spiking and recovery experiments [18]. |

| Chromatography Column | The stationary phase where chemical separation occurs; selection (e.g., C18, C8) is critical for method selectivity. | A C18 column was used for the separation of metoprolol, guanylhydrazones, and polyphenols [1] [17] [20]. |

Validation is the cornerstone of reliable pharmaceutical quality control, transforming an analytical procedure from a simple operation into a scientifically sound and legally defensible tool. For UFLC-DAD technology, a rigorous validation process—assessing parameters from specificity and accuracy to robustness—provides the assurance that data generated is trustworthy for critical decisions regarding drug safety and efficacy. As demonstrated through comparative studies, UFLC-DAD offers a compelling balance of speed, selectivity, and practicality for routine analysis. By adhering to structured validation protocols and understanding the capabilities of their analytical toolkit, researchers and drug development professionals can ensure the consistent production of high-quality pharmaceuticals, ultimately safeguarding public health.

In the field of pharmaceutical analysis, the reliability of analytical data is paramount. Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) has emerged as a powerful technique for the quantification of active pharmaceutical ingredients and impurities. However, the credibility of results generated by any analytical method, including UFLC-DAD, depends on rigorous validation against established performance parameters. Among these, specificity, linearity, accuracy, and precision form the foundational quartet that assures the quality and reliability of analytical outcomes. This guide provides a detailed examination of these four critical validation parameters, supported by experimental data and protocols from recent pharmaceutical research, offering drug development professionals a framework for objective performance assessment.

Core Validation Parameters Explained

Specificity

Specificity is the ability of an analytical method to distinguish and quantify the analyte of interest in the presence of other components that may be expected to be in the sample matrix, such as impurities, degradants, or excipients [1] [24].

Experimental Protocols for Demonstration:

- Forced Degradation Studies: As demonstrated in an Ornidazole stability-indicating assay, specificity is validated by subjecting the drug substance to various stress conditions (acidic, alkaline, oxidative, thermal, and photolytic) and then demonstrating that the method can successfully separate the analyte from its degradation products. Chromatographic peak purity, often assessed via diode array detector (DAD) spectral analysis, confirms the absence of co-eluting peaks [24].

- Resolution of Structurally Similar Compounds: A method developed for guanylhydrazones confirmed specificity by showing baseline separation between three structurally similar compounds (LQM10, LQM14, and LQM17) with retention times of 5.08, 2.64, and 2.18 minutes, respectively. The peaks were confirmed to be free from co-elution, and spectral similarity indices further verified the result [17].

Linearity

Linearity refers to the ability of the method to produce test results that are directly proportional to the concentration of the analyte within a given range [1]. This range is known as the "dynamic range" of the method.

Experimental Protocols for Demonstration:

- A series of standard solutions at different concentration levels across the expected range are prepared and analyzed.

- The peak response (e.g., area) is plotted against the concentration to generate a calibration curve.

- The relationship is typically evaluated by statistical methods, with the coefficient of determination (r²) being a key indicator. A value of >0.995 is generally considered evidence of acceptable linearity [25].

- Example: A UFLC-DAD method for Metoprolol Tartrate (MET) was validated as linear over a specified range. Similarly, a method for Quercetin quantification demonstrated excellent linearity with an R² value greater than 0.995 across nine concentration levels [1] [25].

Accuracy

Accuracy expresses the closeness of agreement between the value found using the method and the value accepted as a true or reference value. It is often reported as % Recovery of the known amount of analyte spiked into the sample matrix [1] [24].

Experimental Protocols for Demonstration:

- Accuracy is determined by analyzing samples spiked with known quantities of the analyte at multiple levels (e.g., 80%, 100%, 120% of the target concentration).

- The measured concentration is compared to the known spiked concentration, and the percentage recovery is calculated.

- Example: In the validation of an Ornidazole HPLC method, average recoveries at the 80%, 100%, and 120% levels were 99.55%, 99.58%, and 99.92%, respectively, well within acceptable limits [24]. Another study on sea buckthorn analysis reported average recoveries for five compounds ranging from 97.36% to 101.19% [26].

Precision

Precision describes the closeness of agreement between a series of measurements obtained from multiple sampling of the same homogeneous sample under prescribed conditions. It is usually expressed as Relative Standard Deviation (RSD %) [1].

Experimental Protocols for Demonstration:

- Repeatability (Intra-day Precision): Multiple injections of the same sample preparation are analyzed in one day by the same analyst using the same equipment.

- Intermediate Precision (Inter-day Precision): The analysis is repeated on a different day, often by a different analyst, to assess the method's robustness within a single laboratory.

- Example: For Quercetin analysis, intra-day precision (repeatability) showed an RSD of ≤ 6.7%, while inter-day precision (intermediate precision) showed an RSD of ≤ 9.4% [25]. A guanylhydrazone method reported inter-day RSD values for peak areas ranging from 1.56% to 2.81% [17].

Comparative Performance Data

The following tables summarize validation data from recent research, providing a benchmark for expected performance of well-characterized UFLC-DAD methods.

Table 1: Validation Parameters for Pharmaceutical Compounds

| Analyte / Matrix | Linearity Range | Accuracy (% Recovery) | Precision (RSD%) | Citation |

|---|---|---|---|---|

| Ornidazole (Gel) | 1–12 μg/mL | 99.55 - 99.92% | Intra-day: 0.179 - 0.879% | [24] |

| Guanylhydrazones (LQM10, LQM14, LQM17) | Not Specified | 98.71 - 101.47% | Inter-day: 1.56 - 2.81% | [17] |

| Metoprolol Tartrate (Tablets) | Not Specified | Validated | Validated | [1] |

| Quercetin (Nanoparticles) | Multi-level (9 points) | 88.6 - 110.7% | Intra-day: ≤ 6.74%Inter-day: ≤ 9.42% | [25] |

Table 2: Validation Parameters for Natural Product Compounds

| Analyte / Matrix | Linearity (R²) | Accuracy (% Recovery) | Precision (RSD%) | Citation |

|---|---|---|---|---|

| Sea Buckthorn Compounds (Pulp/Seed) | > 0.9997 | 97.36 - 101.19% | 0.60 - 2.22% | [26] |

| Wen-Qing-Yin Formula (5 compounds) | 0.9969 - 0.9996 | 88.6 - 112.5% | Not Specified | [27] |

Experimental Workflow for Method Validation

The following diagram illustrates the logical sequence and interrelationships of the key steps in validating an analytical method for specificity, linearity, accuracy, and precision.

Essential Research Reagent Solutions

The following table details key reagents and materials commonly used in UFLC-DAD method development and validation, as evidenced in the cited research.

Table 3: Key Reagents and Materials for UFLC-DAD Analysis

| Reagent/Material | Function in Analysis | Example from Research |

|---|---|---|

| HPLC-Grade Solvents | Act as the mobile phase to carry samples through the chromatographic system. High purity is critical to minimize background noise. | Acetonitrile and Methanol were used in the analysis of Quercetin and Wen-Qing-Yin [25] [27]. |

| Buffers & Acid Modifiers | Modify the pH of the mobile phase to control ionization, improve peak shape, and enhance separation. | 0.1% Formic acid and 1.5% Acetic acid were used in various methods to achieve optimal resolution [25] [27]. |

| Standard Reference Compounds | High-purity analytes used to prepare calibration standards for establishing linearity, accuracy, and precision. | Metoprolol Tartrate (≥98%), Quercetin (≥98%), and other analytical standards were used for quantification [1] [25]. |

| Chromatography Columns | The stationary phase where chemical separation occurs. C18 columns are the most common. | C18 columns such as Agilent ZORBAX SB-C18 and Inertsil ODS C18 are widely used [28] [26]. |

| Membrane Filters | Used to remove particulate matter from samples and mobile phases to protect the instrument and column. | 0.22 μm and 0.45 μm membrane filters were used for sample preparation [26] [24]. |

The rigorous assessment of specificity, linearity, accuracy, and precision is non-negotiable for establishing a reliable UFLC-DAD method in pharmaceutical analysis. As demonstrated by experimental data, well-validated methods consistently achieve high specificity through forced degradation studies, excellent linearity (R² > 0.995), accurate recovery rates (typically 95-105%), and precise results with low RSD values. These four parameters are deeply interconnected, forming a comprehensive framework that ensures the generation of trustworthy data for drug development, quality control, and regulatory submission. Mastery of these concepts empowers scientists to not only validate their methods effectively but also to critically evaluate the quality of analytical data upon which critical decisions are based.

Implementing UFLC-DAD Validation: Protocols for Accuracy, Precision, and Specificity

In pharmaceutical analysis, the reliability of analytical data is paramount for ensuring drug quality, safety, and efficacy. Specificity and selectivity are fundamental validation parameters that demonstrate a method's ability to accurately measure the analyte of interest in the presence of other components that may be expected to be present, such as impurities, degradation products, or matrix components [10]. According to International Council for Harmonisation (ICH) guidelines, specificity is "the ability to assess unequivocally the analyte in the presence of components that may be expected to be present," while selectivity refers to the ability to differentiate and quantify multiple analytes simultaneously [10] [29]. For Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) methods, establishing these parameters ensures that analyte peaks are free from interferences that could compromise accuracy and precision. The recent modernization of analytical guidelines through ICH Q2(R2) and ICH Q14 emphasizes a science- and risk-based approach to validation, reinforcing the critical importance of specificity and selectivity throughout the entire analytical procedure lifecycle [10] [30].

Comparative Performance of Separation Techniques

The fundamental challenge in pharmaceutical analysis lies in adequately separating the target analyte from potentially interfering substances. Different separation and detection techniques offer varying capabilities for establishing specificity and selectivity.

Table 1: Comparison of Analytical Techniques for Specificity and Selectivity Assessment

| Technique | Specificity/Selectivity Mechanism | Typical Applications | Key Advantages | Common Limitations |

|---|---|---|---|---|

| UFLC/HPLC-DAD | Spectral matching + retention time; UV spectrum overlay | Dissolution testing, purity assessment, stability studies | Rapid identification of peak purity; extensive spectral libraries | Limited for structurally similar compounds with identical chromophores |

| UHPLC-MS/MS | Molecular mass + fragmentation patterns (MRM) | Metabolite identification, trace analysis, bioanalytics | Unambiguous identification; extremely high sensitivity and specificity | High instrumentation cost; requires specialized operator training |

| GC-MS | Volatility + mass fragmentation | Residual solvent analysis, volatile impurity profiling | Excellent for volatile/semi-volatile compounds; robust library matching | Requires derivatization for non-volatile pharmaceuticals; thermal degradation risk |

| HPLC-UV/Vis | Retention time + single wavelength | High-concentration analyte quantification | Simplicity; cost-effectiveness; robust for routine QC | Susceptible to co-elution; limited peak purity assessment capability |

Ultra-Fast Liquid Chromatography (UFLC) systems coupled with Diode Array Detection (DAD) provide a significant advantage over conventional HPLC-UV systems through continuous spectral acquisition across multiple wavelengths. This capability enables peak purity assessment by comparing spectra at different peak regions (up-slope, apex, down-slope) [31]. While mass spectrometric detection (MS/MS) offers superior specificity through molecular fingerprinting, UFLC-DAD remains a robust and cost-effective solution for many pharmaceutical quality control applications, particularly when dealing with formulations and stability studies where analyte concentrations are sufficiently high [32].

Experimental Protocols for Specificity and Selectivity Assessment

Forced Degradation Studies

Forced degradation studies represent a critical component of method validation for establishing specificity. These studies involve intentionally stressing the drug substance under various conditions to generate potential degradants, then demonstrating separation of the analyte from these degradation products.

Table 2: Experimental Conditions for Forced Degradation Studies

| Stress Condition | Typical Parameters | Target Degradation | Sample Preparation | Acceptance Criteria |

|---|---|---|---|---|

| Acidic Hydrolysis | 0.1-1M HCl, room temperature to 60°C, 24-72 hours | Esters, amides, lactams | Neutralization before analysis | Baseline separation of main peak from degradants |

| Basic Hydrolysis | 0.1-1M NaOH, room temperature to 60°C, 24-72 hours | Esters, amides, carbamates | Neutralization before analysis | No co-elution; mass balance 90-110% |

| Oxidative Stress | 0.1-3% H₂O₂, room temperature, 24 hours | Sulfides, thiols, susceptible aromatics | Direct injection | Resolution >1.5 between closest eluting peaks |

| Thermal Stress | Solid: 50-70°C; Solution: 40-60°C, up to 30 days | Various degradation pathways | Direct injection or reconstitution | Peak purity index >0.999 |

| Photolytic Stress | UV (320-400 nm) and visible light per ICH Q1B | Photo-labile functional groups | Direct injection | Spectral homogeneity confirmed |

A validated HPLC-DAD method for analyzing polyphenol transformations during black tea processing exemplifies this approach, demonstrating excellent specificity by resolving 12 structurally similar constituents with high resolution, including gallic acid, catechins, and theaflavins [31]. The method achieved superior resolution of co-eluting compounds through optimized mobile phase composition and gradient profile, confirming the system's ability to distinguish analytes with similar chromophores.

Peak Purity Assessment Using DAD

The DAD detector serves as a powerful tool for establishing specificity through peak purity assessment. The experimental protocol involves:

- Spectral Acquisition: Collect full UV-Vis spectra (typically 200-400 nm) at multiple points across the chromatographic peak (up-slope, apex, down-slope)

- Spectral Comparison: Apply algorithm-based matching to compare spectra across the peak

- Purity Threshold: Establish acceptance criteria (typically purity angle < purity threshold)

- Library Matching: Compare unknown peak spectra against reference standard spectra

The purity factor algorithm mathematically evaluates spectral homogeneity, with values closer to 1.000 indicating pure peaks. Modern DAD software incorporates multivariate analysis techniques such as Principal Component Analysis (PCA) to enhance detection of minor spectral differences that might indicate co-elution [31].

Resolution Testing with Related Substances

A comprehensive specificity assessment includes challenging the method with structurally related compounds and synthetic intermediates that may be present in the drug substance. The experimental protocol involves:

- Preparation of Solutions: Individual and mixed solutions of analyte and potential interferents

- Chromatographic Analysis: Injection of individual and mixed solutions

- Resolution Calculation: Determine resolution between closest-eluting peaks (Rs > 2.0 typically required)

- Tailing Factor: Assess peak symmetry (typically ≤ 2.0)

The validation of a UHPLC-MS/MS method for pharmaceutical contaminants in water exemplifies this approach, demonstrating high selectivity for carbamazepine, caffeine, and ibuprofen despite their different chemical structures and the complex environmental matrix [32]. The method achieved this through optimized solid-phase extraction and tandem mass spectrometry detection, though similar principles apply to DAD methods with less complex matrices.

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Essential Research Reagent Solutions for Specificity Assessment

| Reagent/Material | Function in Specificity Assessment | Application Example | Quality/Regulatory Considerations |

|---|---|---|---|

| Pharmaceutical Reference Standards | Provides reference retention times and spectra for target analytes | Quantification and identification of active pharmaceutical ingredients | Certified purity (>98%); stored according to supplier recommendations |

| Related Compound Mixtures | Challenge method specificity with known impurities and degradants | Forced degradation studies; stability-indicating method validation | Well-characterized; includes potential process-related impurities |

| HPLC-Grade Solvents | Mobile phase preparation; sample reconstitution | Ensuring reproducible chromatography and minimal background interference | Low UV absorbance; minimal particulate matter; stored in appropriate containers |

| Buffer Salts and Additives | Mobile phase modification to enhance separation | Improving resolution of closely eluting peaks | HPLC-grade; prepared fresh or with established expiration dating |

| Forced Degradation Reagents | Intentional stress to generate degradation products | Specificity demonstration under ICH guidelines | ACS reagent grade or higher; concentration verified periodically |

Case Study: Validation Data from Pharmaceutical Analysis

A validated UHPLC-MS/MS method for trace pharmaceutical monitoring provides an excellent case study in establishing specificity and selectivity, achieving exceptional sensitivity with limits of detection at ng/L levels (100 ng/L for carbamazepine, 200 ng/L for ibuprofen, and 300 ng/L for caffeine) [32]. The method demonstrated excellent linearity (correlation coefficients ≥ 0.999) and high precision (RSD < 5.0%), with accuracy reflected in recovery rates ranging from 77 to 160% [32]. Although this method employs mass spectrometric detection, the validation approach for establishing specificity follows similar principles applicable to UFLC-DAD methods.

Regulatory Framework and Compliance Considerations

The regulatory framework for analytical method validation has evolved significantly with the introduction of ICH Q2(R2) and ICH Q14 guidelines. These updated guidelines emphasize a lifecycle approach to analytical procedures, with specificity remaining a fundamental validation parameter [10] [30]. The Analytical Target Profile (ATP) concept introduced in ICH Q14 requires prospective definition of method performance criteria, including specificity requirements, before method development begins [10]. This systematic approach ensures that methods are designed to be fit-for-purpose from the outset, rather than relying on retrospective validation [10].

Regulatory submissions must demonstrate specificity through comprehensive documentation of forced degradation studies, peak purity assessments, and resolution testing. The FDA and other regulatory agencies expect science-based justification of the chosen chromatographic conditions and their ability to separate the analyte from potential interferents [33]. For pharmaceutical analysis, this is particularly critical for stability-indicating methods that must detect and quantify degradation products under ICH stability testing conditions [29].

Establishing specificity and selectivity represents a critical foundation for any validated UFLC-DAD method in pharmaceutical analysis. Through systematic assessment of peak purity, forced degradation studies, and resolution testing, analysts can demonstrate that their methods accurately quantify target analytes free from interference. The evolving regulatory landscape, with its emphasis on lifecycle management and science-based validation, reinforces the importance of robust specificity testing throughout a method's operational lifetime. As analytical technologies advance, the fundamental requirement remains unchanged: providing defensible scientific evidence that analytical results are reliable, accurate, and fit for their intended purpose in ensuring drug quality and patient safety.

In pharmaceutical analysis, the validation of analytical methods is fundamental to ensuring the reliability, accuracy, and reproducibility of data. Among the various validation parameters, linearity and range are critical for establishing that an analytical procedure can obtain test results that are directly proportional to the concentration of the analyte in a given sample [10]. For techniques like Ultra-Fast Liquid Chromatography coupled with a Diode Array Detector (UFLC-DAD), demonstrating acceptable linearity across a specified range is a prerequisite for generating confidence in quantitative results, from drug development to quality control [1].

This guide objectively compares the performance of UFLC-DAD with alternative techniques, namely conventional spectrophotometry, in establishing linearity and range. The comparison is framed within a broader thesis on validation parameters for UFLC-DAD, providing researchers and drug development professionals with experimental data and protocols to support their analytical method selection and validation.

The following table summarizes a direct comparison of linearity and range performance between UFLC-DAD and spectrophotometry, based on experimental data from the analysis of metoprolol tartrate (MET) [1].

| Feature | UFLC-DAD | UV-Vis Spectrophotometry |

|---|---|---|

| Applicable Tablet Dosage | 50 mg and 100 mg MET tablets [1] | Limited to 50 mg MET tablets due to concentration constraints [1] |

| Typical Analytical Range | Wider dynamic range [1] | Narrower range, limited by Beer-Lambert law deviations at higher concentrations [1] |

| Specificity in Complex Matrices | High (separation step eliminates interferences) [1] | Lower (susceptible to matrix interference and overlapping bands) [1] |

| Key Operational Advantage | Speed, simplicity, and selectivity from chromatographic separation [1] | Simplicity, precision, low cost, and wide instrument availability [1] |

| Environmental Impact (AGREE Metric) | Environmentally friendly process [1] | Environmentally friendly process [1] |

This comparative data highlights that while spectrophotometry is a valuable, cost-effective tool for simpler analyses, UFLC-DAD offers a more robust solution for assays requiring a wider dynamic range and higher specificity, such as the analysis of multiple tablet dosages or complex sample matrices.

Experimental Protocols for Establishing Linearity and Range

Protocol 1: UFLC-DAD Method for Metoprolol Tartrate

This protocol is adapted from a study that performed a comparative analysis and validation for quantifying metoprolol tartrate in pharmaceuticals [1].

- 1. Instrumentation: Ultra-Fast Liquid Chromatography system equipped with a Diode Array Detector.

- 2. Standard Solution Preparation: An appropriate mass of MET reference standard (≥98% purity) is accurately weighed and dissolved in ultrapure water to prepare a stock solution. A series of standard solutions are prepared from this stock via dilution to cover the expected concentration range (e.g., for 50 mg and 100 mg tablets) [1].

- 3. Chromatographic Conditions:

- 4. Calibration Curve Construction: The standard solutions are injected, and the peak areas (or heights) are recorded. A calibration curve is constructed by plotting the instrument response against the corresponding concentration of the standard solutions.

- 5. Data Analysis: The linearity is evaluated using the determination coefficient (R²) and the correlation coefficient (r). Statistical analysis of the calibration curve, including the slope, intercept, and their confidence intervals, is performed to confirm the linear relationship [1].

Protocol 2: HPLC-DAD Method for Quercetin in Nanoparticles

This protocol provides a detailed example of linearity assessment for a different compound, quercetin, showcasing a broader application of DAD-based chromatography [3].

- 1. Instrumentation: High-Performance Liquid Chromatography system with a Diode Array Detector.

- 2. Optimal Conditions:

- 3. Calibration Curve Construction: A calibration curve was constructed using nine standard concentrations ranging from 0.14 to 245 µg/mL [3].

- 4. Data Analysis:

- Linearity Assessment: The determination coefficient (R²) was calculated to be >0.995, demonstrating excellent linearity [3].

- Back-Calculation: The concordance of back-calculated concentrations was used to verify the curve's adequacy across its range, with accuracy ranging between 88.6% and 110.7% [3].

- Sensitivity: The Limit of Detection (LOD) and Limit of Quantification (LOQ) were determined to be 0.046 µg/mL and 0.14 µg/mL, respectively [3].

The workflow for developing and validating the linearity and range of a method is systematic, as illustrated below.

The Scientist's Toolkit: Essential Research Reagent Solutions

The table below details key reagents and materials commonly used in developing and validating linearity for UFLC-DAD methods, based on the cited experimental protocols.

| Item Name | Function in Experiment |

|---|---|

| Metoprolol Tartrate (MET) Reference Standard | Serves as the high-purity (>98%) analyte for preparing calibration standards and assessing method accuracy [1]. |

| Quercetin Standard | The flavonol analyte used for method development and validation in nanoparticle and complex matrix analysis [3]. |

| Ultrapure Water (UPW) | The solvent of choice for preparing standard stock and working solutions, minimizing interference [1]. |

| HPLC-Grade Acetonitrile and Methanol | Critical components of the mobile phase for achieving optimal chromatographic separation and peak shape [3]. |

| Acetic Acid (Pro Analysis Grade) | Used as a mobile phase modifier (acidifier) to control pH and improve chromatographic performance [3]. |

| Ammonium Metavanadate | A derivatization agent used in DAD-based methods for detecting non-chromophoric analytes like hydrogen peroxide [34]. |

The establishment of linearity and a defined range is a cornerstone of a reliable analytical method. As demonstrated, UFLC-DAD provides a distinct advantage over spectrophotometry in terms of dynamic range, specificity, and applicability to more complex analytical challenges, such as quantifying active ingredients across different pharmaceutical dosage forms. By adhering to rigorous experimental protocols and understanding the capabilities of each technique, researchers can effectively develop and validate robust methods that ensure the quality, safety, and efficacy of pharmaceutical products.

Recovery studies are a fundamental component of analytical method validation in pharmaceutical development, serving to demonstrate that an analytical method can accurately measure the analyte of interest from a given sample matrix. Method validation is crucial for ensuring the reliability, accuracy, and reproducibility of analytical measurements, with the primary goal of demonstrating that an analytical method is suitable for its intended purpose [1]. In pharmaceutical analysis, every future measurement in routine analysis must be close enough to the true value for the content of the analyte in the sample, making robust accuracy protocols essential for quality control.

The process of recovery determination involves quantifying the proportion of an analyte that can be reliably extracted and measured from a specific matrix, whether it's a dosage form, manufacturing equipment surface, or biological sample. Regulatory bodies including the FDA, ICH, WHO, and EMA mandate recovery assessments as part of comprehensive validation packages for pharmaceutical methods. According to ICH guidelines, key parameters that must be evaluated during method validation include linearity, specificity/selectivity, limit of detection (LOD), limit of quantification (LOQ), precision, accuracy, robustness, and range of analysis [3]. These elements collectively ensure that analytical methods provide trustworthy data for critical decisions in drug development and quality assurance.

Comparative Analysis of Analytical Techniques for Recovery Studies

UFLC-DAD Versus Spectrophotometric Methods

Ultra-Fast Liquid Chromatography with Diode Array Detection (UFLC-DAD) and spectrophotometry represent two complementary approaches for pharmaceutical analysis, each with distinct advantages and limitations for recovery studies. A comparative study analyzing metoprolol tartrate (MET) in commercial β-blocker tablets demonstrated that UFLC-DAD successfully covered 50 mg and 100 mg tablets, while the spectrophotometric method was explicitly applied only to analyze the 50 mg tablets due to concentration limitations [1]. This highlights a key constraint of spectrophotometric methods—their limited dynamic range compared to chromatographic techniques.

The same study reported that statistical analysis, including ANOVA and Student's t-test, indicated that both validated methods were suitable for routine analysis of MET in commercial tablets [1]. However, UFLC-DAD analysis offers superior selectivity and sensitivity in analyzing organic compounds and quantifying isolated substances, making it particularly valuable for complex formulations. UFLC contributes shorter analysis time, increased peak capacity, and lower consumption of samples and solvents compared to conventional HPLC methods [1] [2]. Spectrophotometry remains popular due to procedural simplicity, instrument availability, precision, speed, and accuracy, but struggles with overlapping bands of analytes and interferences that make quantitative data analysis complex [1].

HPLC-DAD Versus UHPLC-UV for Compound Analysis

Chromatographic techniques have evolved significantly, with High-Performance Liquid Chromatography (HPLC) and Ultra-High-Performance Liquid Chromatography (UHPLC) offering different benefits for pharmaceutical analysis. A comparative study of newly developed HPLC-DAD and UHPLC-UV assays for posaconazole quantification revealed distinct practical differences [35]. The run time was significantly shorter for UHPLC-UV (3 minutes) compared to HPLC-DAD (11 minutes), enhancing laboratory efficiency. Both assays demonstrated excellent linearity (r² > 0.999) with CV% and percentage error of the mean below 3%, indicating comparable accuracy between the techniques [35].

Table 1: Comparison of HPLC-DAD and UHPLC-UV Methods for Posaconazole Analysis

| Parameter | HPLC-DAD | UHPLC-UV |

|---|---|---|

| Run Time | 11 minutes | 3 minutes |

| Linear Range | 5–50 μg/mL | 5–50 μg/mL |

| Correlation Coefficient (r²) | >0.999 | >0.999 |

| Limit of Detection | 0.82 μg/mL | 1.04 μg/mL |

| Limit of Quantification | 2.73 μg/mL | 3.16 μg/mL |

| Injection Volume | 20-50 μL | 5 μL |

| Solvent Consumption | Higher | Four times less |

For guanylhydrazone derivatives with anticancer activity, researchers developed both HPLC and UHPLC methods, finding that the UHPLC method was more economical, with four times less solvent consumption and 20 times smaller injection volume, which allowed for better column performance [36]. The factorial design approach used for UHPLC method development made the process faster, more practical, and rational compared to the empirical approach employed for HPLC development [36].

swab Sampling Methods for Cleaning Validation

Recovery studies for cleaning validation in pharmaceutical manufacturing employ both swab and rinse sampling techniques. A comprehensive evaluation of these procedures found that recovery rates vary significantly based on surface material and sampling method [37]. For swab sampling, recovery ranged from 63.88% for stainless steel to higher values for less porous materials, while rinse sampling of PVC surfaces achieved 97.85% recovery [37]. This highlights how surface characteristics and sampling methodology directly impact recovery efficiency.

Table 2: Recovery Rates by Surface Material and Sampling Method

| Surface Material | Sampling Method | Recovery Rate (%) |

|---|---|---|

| Stainless Steel | Swab | 63.88 |

| PVC | Rinse | 97.85 |

| Polyester | Rinse | Data not specified |

| Poly (methyl methacrylate) | Swab | Data not specified |

Parameters affecting cleaning validation swab recovery studies include: the material of construction coupon, residue spike level(s), swab type, swab personnel, swab extraction, and test method [38]. Best practices recommend using the average of recovery data sets as the recovery factor for all cleaning samples, rather than using the single lowest recovery, which could cause samples near the Acceptable Residue Limit (ARL) to fail cleaning when they actually pass [38].

Experimental Protocols for Recovery Studies

swab Recovery Methodology

Swab recovery studies follow a systematic process to determine the efficiency of residue recovery from equipment surfaces. The process begins with preparing sample equipment materials of construction (MOC) coupons spiked with known amounts of the substance of interest [38]. These coupons should represent the actual product-contact surfaces within the manufacturing equipment. The recommended strategy for recovery levels is to spike 125% of the ARL, 100% of the ARL, and 50% of the ARL at a minimum, extending down to the LOQ of the test method as practical [38]. All recovery levels should be performed in triplicate to account for methodological variability.

The swabbing procedure itself requires standardization. For a 5 cm × 5 cm area (25 cm²), which has been accepted as large enough for a representative sample size, the process typically involves using two swabs subsequently [38] [37]. The first swab is wetted with an appropriate solvent (such as purified water), followed by a second dry swab. The sample is prepared by wiping horizontally on one side of the swab, flipping the swab, and wiping vertically on the other side [37]. Each swab sample is then placed in a test tube for extraction. Desorption of the swabs and extraction of residues is typically accomplished by adding a solvent mix (e.g., methanol and water in 60:40 ratio) and hand shaking for approximately 2 minutes [37].

Diagram 1: Swab Recovery Study Workflow

Chromatographic Method Validation for Recovery Assessment

For chromatographic methods such as UFLC-DAD, recovery studies are integrated into broader method validation protocols. The process begins with method optimization, assessing parameters like mobile phase composition, detection wavelength, column type, and flow rate to achieve optimal separation [3] [35]. For quercetin analysis in nanoparticles, researchers tested different mobile phase conditions and detection wavelengths (254 and 368 nm), finding that the best peak resolution was obtained at 368 nm with a mobile phase of 1.5% acetic acid and a water/acetonitrile/methanol ratio of 55:40:5 [3].

Once optimal conditions are established, method validation assesses key parameters including specificity/selectivity, sensitivity, linearity, dynamic range, LOD, LOQ, accuracy, precision, and robustness [1]. For the posaconazole HPLC-DAD and UHPLC-UV methods, intraday accuracy and precision were determined using three sample replicates of 5, 20, and 50 μg/mL of PSZ, with interday assessments repeated on three separate days [35]. Precision was determined using percentage coefficient of variation (CV%), while bias was assessed using mean intra- or interday percentage error of the mean [35].

Acceptance Criteria Frameworks

Establishing Method Acceptance Criteria

Acceptance criteria for analytical methods must be carefully established to ensure methods are fit for their intended purpose while controlling product quality. Traditional measures of analytical goodness include % coefficient of variation (CV) = (repeatability/mean)×100, % recovery = (measured concentration/standard concentration)×100, and R-square of a curve comparing theoretical concentration to method signal [39]. However, these traditional approaches have limitations, as they may falsely indicate a method is performing poorly at low concentrations when it is actually performing excellently, or appear acceptable at high concentrations when actually unacceptable relative to product specifications.

A more sophisticated approach evaluates method error relative to the product specification tolerance or design margin. The fundamental equations governing this relationship are:

- Product Mean = Sample Mean + Method Bias [39]

- Reportable Result = Test sample true value + Method Bias + Method Repeatability [39]

- Tolerance = Upper Specification Limit (USL) - Lower Specification Limit (LSL) [39]

Recommended acceptance criteria for analytical methods include repeatability as ≤25% of tolerance and bias as ≤10% of tolerance [39]. For bioassays, slightly wider acceptance criteria may be appropriate, with repeatability ≤50% of tolerance while maintaining bias ≤10% of tolerance [39].

Recovery Study Acceptance Criteria

For recovery studies specifically, acceptance criteria help determine whether recovery efficiency is sufficient for reliable analytical measurements. According to WHO guidelines, a recovery of >80% is considered good [40]. However, context is important—recoveries between 70-100% are generally acceptable, with consistent, reproducible data being more critical than achieving an arbitrary minimum value [38].

Recovery factors are determined through experiments in which sample equipment materials of construction are spiked with known amounts of the substance of interest, then recovered and tested. The resulting data should demonstrate consistency, with variability typically limited to <15% RSD, although experienced personnel can often achieve <10% RSD [38]. While single recoveries up to 105% can be considered acceptable, any recovery greater than 105% should be considered suspect and investigated [38].

Table 3: Acceptance Criteria for Key Analytical Parameters

| Validation Parameter | Acceptance Criteria | Application Context |

|---|---|---|

| Specificity/Selectivity | Excellent: ≤5% of tolerance; Acceptable: ≤10% of tolerance | Analytical methods [39] |

| Repeatability | ≤25% of tolerance | Analytical methods [39] |

| ≤50% of tolerance | Bioassays [39] | |

| Bias/Accuracy | ≤10% of tolerance | Analytical methods and bioassays [39] |

| LOD | Excellent: ≤5% of tolerance; Acceptable: ≤10% of tolerance | Analytical methods [39] |

| LOQ | Excellent: ≤15% of tolerance; Acceptable: ≤20% of tolerance | Analytical methods [39] |

| swab Recovery | >80% (good), 70-100% (generally acceptable) | Cleaning validation [40] [38] |

| Recovery Variability | <15% RSD (acceptable), <10% RSD (experienced personnel) | Cleaning validation [38] |

Research Reagent Solutions for Recovery Studies

The following essential materials and reagents are critical for conducting recovery studies in pharmaceutical analysis:

UFLC-DAD System: Ultra-Fast Liquid Chromatography system with Diode Array Detection for high-speed, high-resolution separation and quantification of pharmaceutical compounds. Provides shorter analysis time, increased peak capacity, and reduced solvent consumption compared to conventional HPLC [1] [2].

HPLC-UV/Vis System: High-Performance Liquid Chromatography with Ultraviolet/Visible detection for reliable compound separation and quantification. Versatile and widely available, with methods that can be optimized for specific compounds like posaconazole through mobile phase and column selection [3] [35].

Reference Standards: Certified reference materials of known purity and concentration, such as USP-grade standards, essential for method calibration and accuracy determination. Required for preparing calibration curves and assessing method bias [37] [35].

swab Sampling Materials: Appropriate swabs (e.g., Alpha swabs, Texwipe 761) for surface recovery studies. Selection of proper swab material is critical for efficient recovery without introducing interference [37].